Energy-saving and compact type guide rail clamping device

A clamper, compact technology, applied in the direction of brake parts, brake parts, brake types, etc., can solve the problems of small effective space, poor machining accuracy, etc., achieve wide application range, large braking force, and avoid guide rail scratches The effect of injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

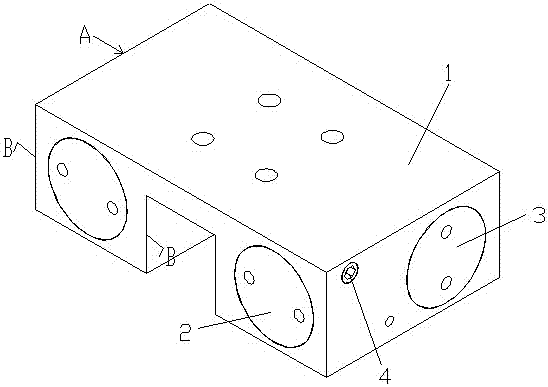

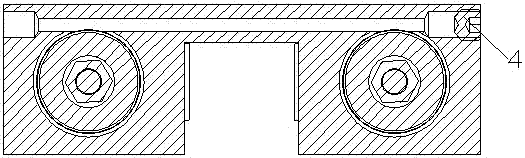

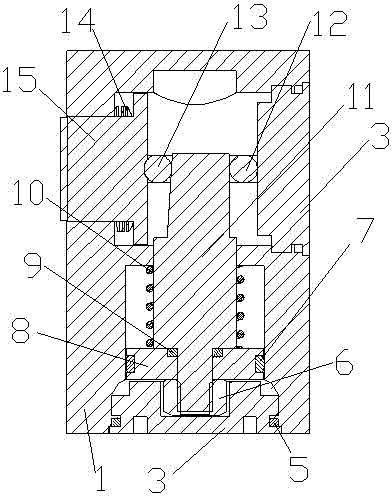

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10As shown, a normally open guide rail clamp has a symmetrical main structure with left and right ends, and each end is composed of a clamp body 1, a cylinder cover 2, a clamp support block 3, a sealing screw 4, and a cylinder cover sealing ring 5 , cylinder rod fixing nut 6, piston sealing ring 7, piston 8, cylinder rod sealing ring 9, compression spring 10, cylinder rod 11, clamping A guide post 12, clamping B guide post 13, spring washer 14 and clamping block 15, The spring washer 14 is a wave spring washer or a butterfly spring washer. The clamp body 1 is set to fasten the fixed thread 1-1 on the line rail and the air outlet hole 1-3 of the cylinder, and the air inlet threaded hole 1 of the clamp body 1 -2 communicates with the air inlet 1-4 and is used to connect the air inlet joint and the sealing screw 4, the air inlet 1-4 is arrang...

example 2

[0035] Such as Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 and Figure 16 As shown, a normally closed guide rail clamp has a symmetrical main structure with left and right ends, and each end is composed of a clamp body 1, a cylinder cover 2, a clamp support block 3, a sealing screw 4, and a cylinder cover sealing ring 5 , cylinder rod fixing nut 6, piston sealing ring 7, piston 8, cylinder rod sealing ring 9, compression spring 10, cylinder rod 11, clamping A guide post 12, clamping B guide post 13, spring washer 14 and clamping block 15, The spring washer 14 is a wave spring washer or a butterfly spring washer. The clamp body 1 is set to fasten the fixed thread 1-1 on the line rail and the air outlet hole 1-3 of the cylinder, and the air inlet threaded hole 1 of the clamp body 1 -2 communicates with the air inlet 1-4 and is used to connect the air inlet joint and the sealing screw 4, the air inlet 1-4 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com