Slag discharging device and method for biomass gasifying furnace

A gasification furnace and biomass technology, applied in the field of gasification furnaces, can solve the problems of not being able to maintain the airtightness of the gasification furnace, high-pressure water consumption, etc., and achieve simple structure, ensure airtightness, and good slagging effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

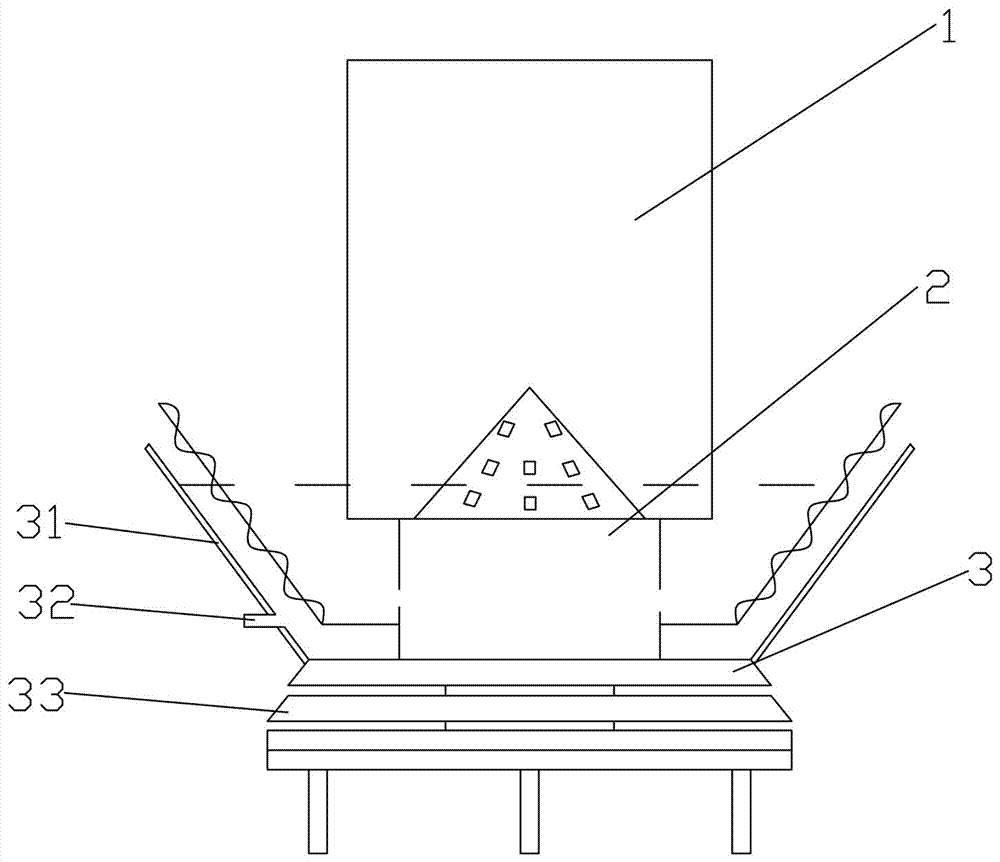

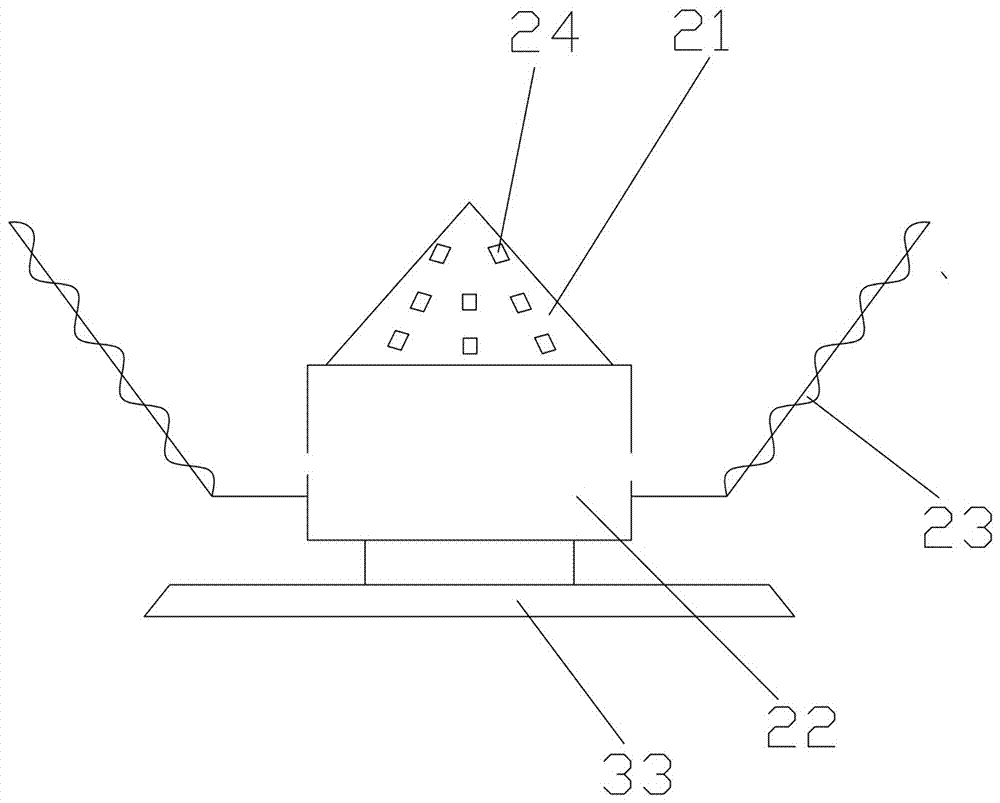

[0035] Embodiment one: as attached Figures 1 to 2 As shown, it is only one embodiment of the present invention, a biomass gasification furnace slagging device, including a furnace body 1: the furnace body 1 is a columnar body with an open lower end; a slagging table 2: the slagging The platform 2 can rotate around its center. The slag discharge platform 2 includes a cone row 21 arranged above, a hollow slag discharge chamber 22 and a slag discharge rack 23 arranged below; the water tray 3: includes a water storage tray 31, an outlet A nozzle 32 and a drive frame 33 for driving the slag discharge table 2 to rotate.

[0036] In the above device, the size of the opening at the lower end of the furnace body 1 is the same as the size of the upper end of the slag discharge bin 22, and the upper end of the slag discharge bin 22 is circular, so the slag discharge bin 22 can effectively extend into the furnace body 1, and the furnace body 1 remains Airtight, the biomass raw material ...

Embodiment 2

[0039] Embodiment two: as attached Figures 1 to 3 As shown, it is only one embodiment of the present invention. After the residue is discharged into the water tray 3 , it is still necessary to further discharge the residue in the water tray 3 .

[0040] A slag discharge frame 23 is connected outside the slag discharge bin 22, and the slag discharge frame contacts with the inner wall of the water tray 22, and the residue in the water tray 3 is discharged from the water tray 3.

[0041] In the above solution, the number of slag discharge racks 23 is not less than 2, and the slag discharge capacity is enhanced.

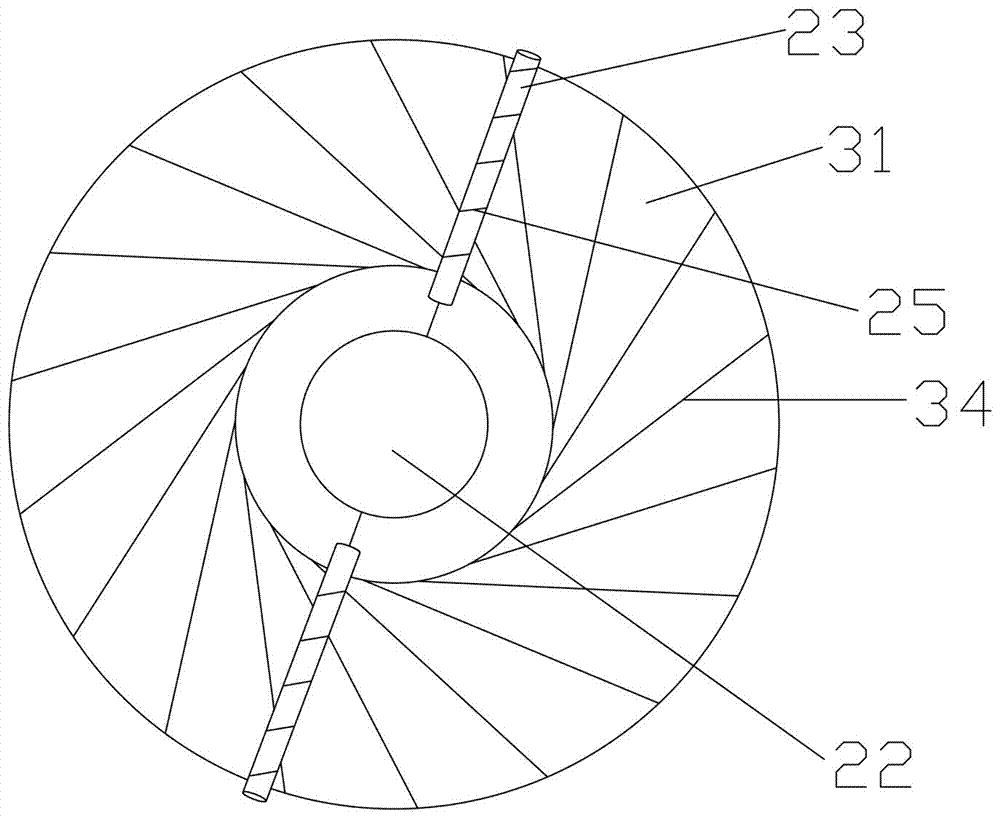

[0042] In the above solution, the inner wall of the water storage tray 31 is provided with a rolling groove 34 for facilitating the rolling of the slag discharge rack 23 .

[0043] In the above solution, the slag discharge frame 23 is provided with a helical tooth 25 corresponding to the roll groove 34 .

[0044] The shape of the slag discharge rack 23 is helical and ...

Embodiment 3

[0046] Embodiment three: a kind of biomass gasifier slagging method, comprises the following steps:

[0047] S1. Fill the water tray with water to prevent the gas from leaking out of the furnace body;

[0048] S2, the slag discharge table rotates, and the residue in the furnace is introduced into the water tray through the slag discharge table;

[0049] S3. The slag discharge table drives the slag discharge frame to rotate on the inner wall of the water tray to take out the residue.

[0050] In the above method, all the water in the water tray is discharged regularly, and then water is injected again, and the height of the water surface does not exceed the slag discharge chamber in the slag discharge table.

[0051] In the above method, step S2 specifically includes: the slag discharge table is a hollow slag discharge table, and the upper part of the slag discharge table is conical, so that the residue enters the slag discharge table from the furnace body, and then rotates to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com