A thermoplastic elastomer gasket material and its production method

A technology of thermoplastic elastic and sheet materials, which is applied in the field of thermoplastic elastomer gasket materials, can solve the problems of contaminated liquid medicine, long processing cycle, and complicated processing of butyl rubber plugs, and achieve good rebound and pressure change characteristics, Effect of improving anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Material pretreatment: 1) SEBS is added with filler oil and stirred at high speed for 5 minutes, the temperature is controlled at 30°C-70°C and then allowed to stand for 48 hours; 2) Add silane coupling agent diluted with glycerol to the nano filler, glycerol: Silane coupling agent = 3:1, mix at low speed for 120 seconds, then dry and set aside.

[0018] Mixing: Weigh the materials according to the requirements, add POK resin, EPDM, oil-filled SEBS, nano fillers treated with silane coupling agent, antioxidant, and lubricant respectively into the mixer, mix at low speed for 120 seconds, and mix at high speed After mixing for 60 seconds, pour into the hopper of the extruder, extrude, granulate and pack with a twin-screw extruder.

[0019] The temperature of each section of the twin-screw is 85-105°C, 140-160°C, 160-200°C, 160-200°C, 160-200°C, 160-190°C, 160-190°C, 160-190°C. The temperature is 160-175°C.

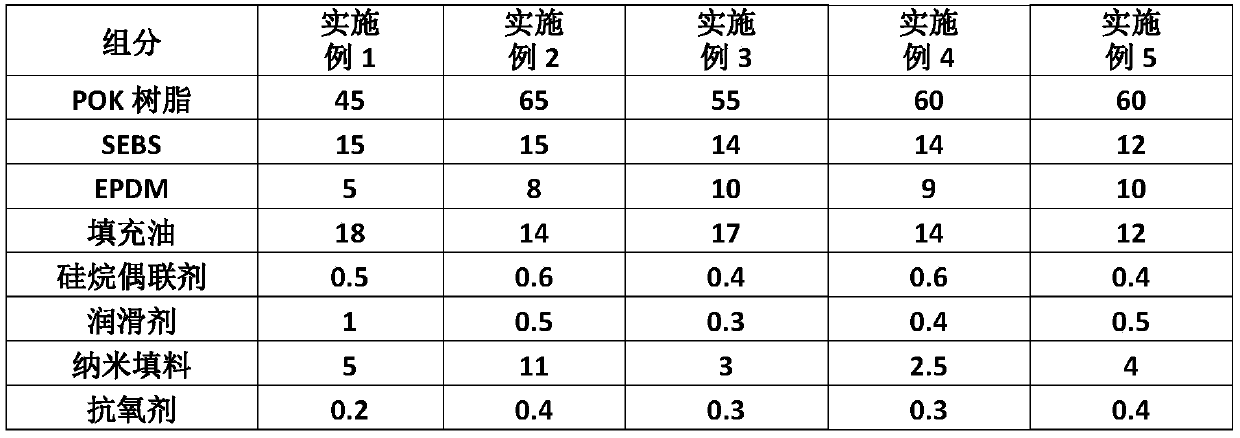

[0020] Table 1 Example

[0021]

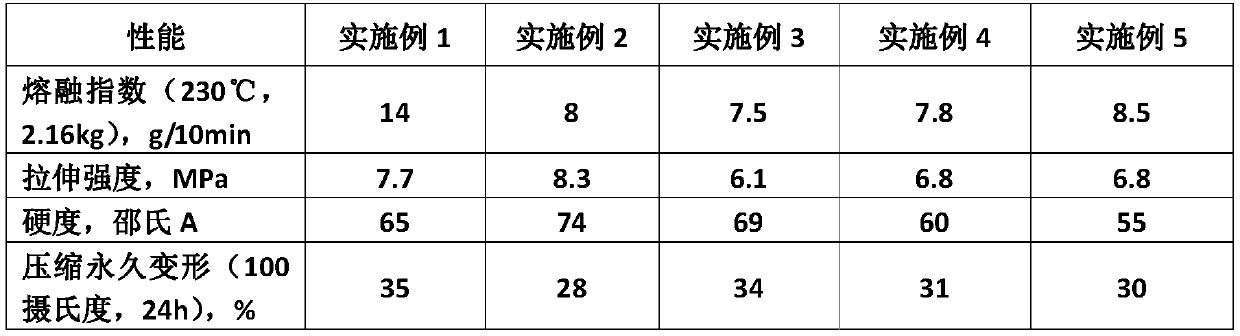

[0022] The performance pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com