Modified ultrafine glass fiber cotton with high specific surface area for AGM partition and preparation method thereof

A technology of ultra-fine glass fiber and high specific surface area, which is applied in glass manufacturing equipment, manufacturing tools, electrical components, etc., can solve the problems of AGM separator uniformity, tensile strength rebound rate, and poor oxygen recombination efficiency. Achieve the effects of improving oxygen recombination efficiency, reducing viscosity, and reducing expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

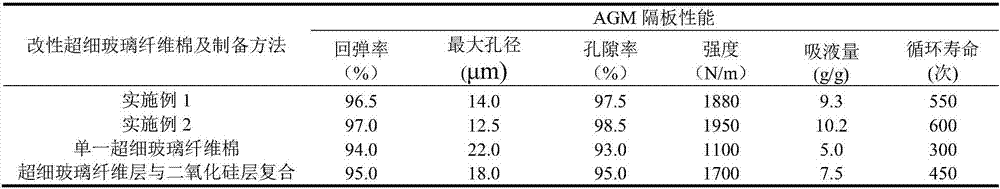

Embodiment 1

[0023] Preparation of modified ultrafine glass fiber wool for AGM separators with high specific surface area

[0024] Weigh 32 parts of quartz sand, 8.5 parts of albite, 4 parts of potassium feldspar, 13.5 parts of soda ash, 8.5 parts of dolomite, 4 parts of calcite and 9.5 parts of borax according to the mass ratio, put them into the kiln for calcination after uniform mixing, and melt into The temperature of the obtained glass liquid is 1095°C; then the glass liquid is drawn once, and then blown by a flame at 1015°C to form ultra-fine glass fibers. The B in the ultra-fine glass fiber cotton 2 o 3 The content is 5.8wt%, Fe 2 o 3 The content is 0.05wt%, 95% of its diameter is normally distributed at 1.2μm, and its length is 90% normally distributed at 2.4mm. At the same time, according to the injection pressure of 0.45MPa and the injection flow rate of 165kg / h, the particle diameter of KH550 and KH560 will be mixed It is 55nm nano-scale fumed silica powder uniformly atomized...

Embodiment 2

[0026] Preparation of modified ultrafine glass fiber wool for AGM separators with high specific surface area

[0027] Weigh 33.5 parts of quartz sand, 10.5 parts of albite, 4.5 parts of potassium feldspar, 12 parts of soda ash, 9.5 parts of dolomite, 3.5 parts of calcite and 11.5 parts of borax according to the mass ratio, put them into the kiln for calcination after uniform mixing, and melt into The temperature of the obtained glass liquid is 1110°C; then the glass liquid is drawn once, and then blown by a flame at 1020°C to form ultra-fine glass fibers. The B in the ultra-fine glass fiber cotton 2 o 3 The content is 6.3wt%, Fe 2 o 3The content is 0.02wt%, 95% of its diameter is normally distributed at 0.8μm, and its length is 90% normally distributed at 2.8mm. At the same time, according to the injection pressure of 0.5MPa, the injection flow rate of 180kg / h will mix KH792 and NDZ-311 The particle diameter is 40nm nano-scale fumed silica powder evenly atomized and sprayed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com