Foamed net conveying equipment for apple packing

A technology for conveying equipment and packaging, which is applied in the field of foam net conveying equipment for apple packaging, which can solve the problems of low production efficiency, troublesome operation, and discontinuous apples, and achieve the goals of reducing work stations, improving work efficiency, and simplifying the packaging process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

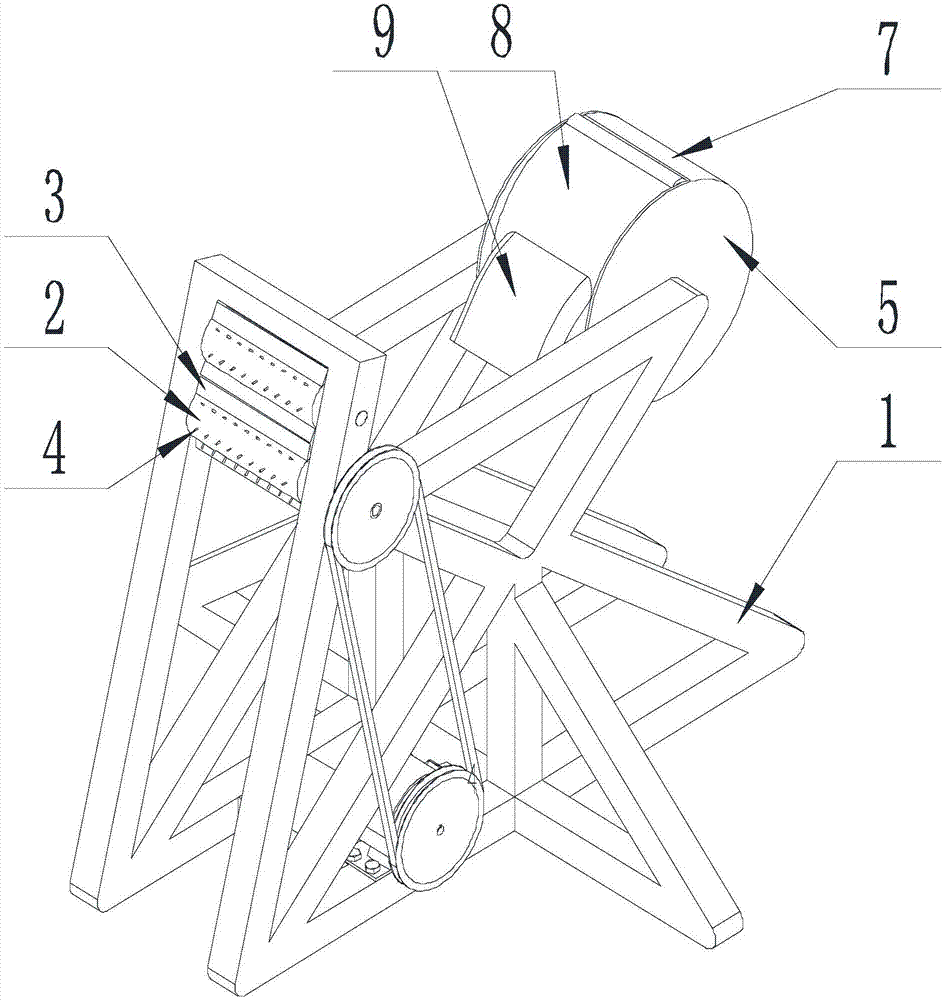

[0044] Such as Figure 1-Figure 6As shown, the foam net conveying equipment for apple packaging of the present invention includes a cutting assembly, a driving device and a support frame 1, and the support frame 1 supports the cutting assembly on the ground, and the cutting assembly includes a pair of installations whose axes are parallel to each other. The shaft 2 is provided with a cutter 3 and a locking rod 4 on the installation shaft 2, the blade of the cutter 3 is parallel to the axis of the installation shaft 2, and both ends of the installation shaft 2 are connected to the support frame 1 in rotation , and the driving device drives the mounting shafts 2 to rotate around their own axes respectively, and makes the blades of the cutters 3 contact each other, and the rotation direction of the mounting shafts 2 is opposite.

[0045] One end of the foamed net rolled into a roll is sleeved on the clamping rod 4 through the mesh on it, and the side of the foamed net close to a ...

Embodiment 2

[0048] This embodiment is based on Embodiment 1 to further illustrate the present invention.

[0049] Such as Figure 1-Figure 6 As shown, in the present invention, the foaming net conveying equipment for apple packaging is provided with a net storage box 5 on the support frame 1, and on the side wall of the net storage box 5, an end close to the cutter 3 is provided with a net communicating with the inner cavity. The material guide hole is provided with a positioning shaft 6 in the inner cavity of the net storage box 5, and the axis of the positioning shaft 6 is parallel to the axis of the installation shaft 2.

[0050] Set the rolled foam net on the positioning shaft 6, and the farthest end of the foam net from the positioning shaft 6 passes through the material guide hole and is set on the clamping rod 4 through its own mesh to carry out Cutting of foam net and packaging process of apples.

[0051] Further, the net storage box 5 is cylindrical, the axis of which coincides...

Embodiment 3

[0057] This embodiment is based on Embodiment 1 to further illustrate the present invention.

[0058] Such as Figure 1-Figure 6 As shown, in the foam net conveying equipment for apple packaging of the present invention, each of the installation shafts 2 is provided with two cutters 3, and the cutters 3 are symmetrical along the axis of the corresponding installation shaft 2, and the same installation shaft Positioning rods 4 are arranged on the side walls between the cutting knives 3 on the top 2.

[0059] Set the diameter of the installation shaft 2 according to the length of the foam net package required, so that every time the installation shaft 2 completes one rotation, just complete the cutting of the foam net twice, so as to improve work efficiency.

[0060] Furthermore, three rows of clamping rods 4 are arranged on the side wall between the cutters 3 on the same installation shaft 2 , and the arrangement direction of each row of clamping rods 4 is parallel to the axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com