Testing apparatus for testing slagging resistance of material

A test device and slagging technology, which is applied in the direction of chemical analysis by combustion, can solve the problems of long time spent, waste of manpower and material resources, etc., and achieve the effect of easy blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

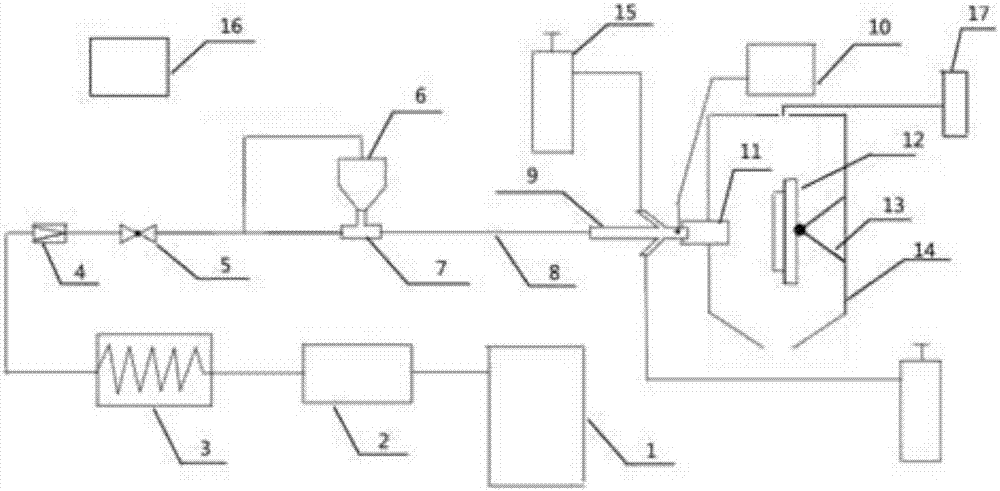

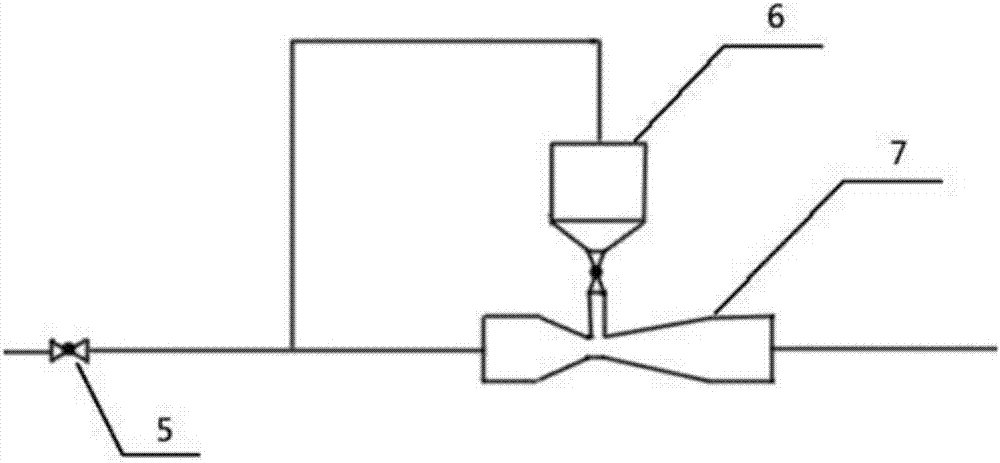

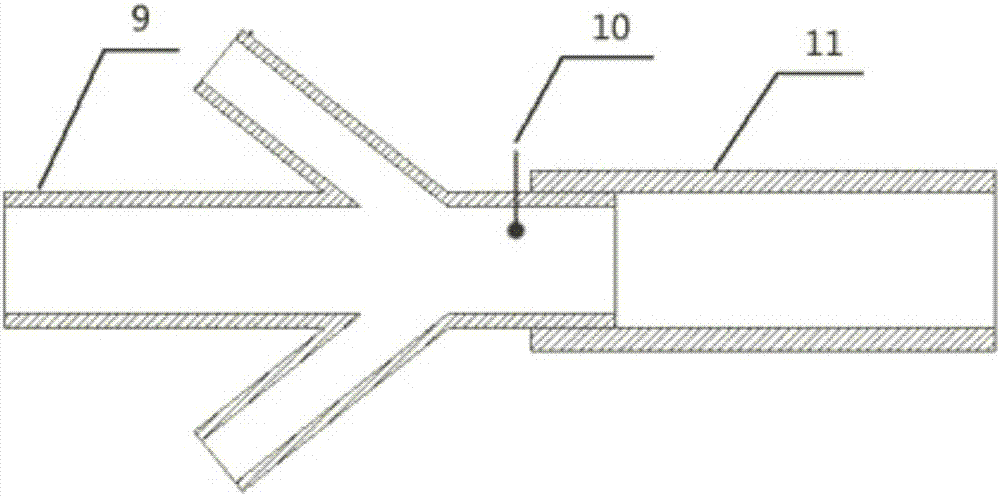

[0020] Such as figure 1 As shown, the present invention includes an air compressor 1 connected by pipelines, a refrigerated dehumidifier 2, an air preheater 3, a pressure reducing valve 4, and a ball valve 5. The compressed air is divided into two paths after passing through the ball valve 5, and one path is connected to the pulverized coal bin 6 upper end, the other way enters the Venturi feeder 7 and enters the acceleration pipe 8 after mixing with the falling coal powder, and enters the mixing chamber 9 after the acceleration is completed. The left and right sides of the mixing chamber 9 are equipped with methane inlets and Bottles 15 are connected, compressed air, pulverized coal and methane are fully mixed, ignited by ignition controller 10 and enter nozzle 11 for combustion and injection. The nozzle 11 is facing the sample stand 13, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com