Compressing type subsealing packer

A packer, compression technology, applied in sealing/packing, production fluid, wellbore/well components, etc., can solve the problems of low construction efficiency, unable to meet the requirements of multiple stages of packer-driven fracturing, etc. The effect of unblocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

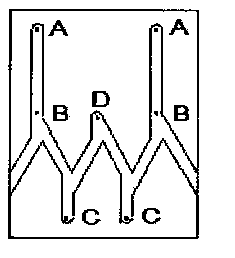

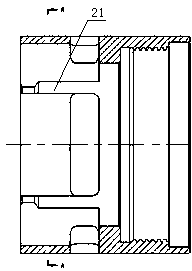

[0027] In order to overcome the problem that the conventional fracturing packer in the prior art is used as a bottom seal packer, the construction efficiency is low, and the problem that the packer cannot meet the requirements of multiple stages of dragging and fracturing when the packer goes down the well at one time, this embodiment provides a method such as figure 1 , figure 2 , image 3 The shown compression bottom seal packer includes a reversing centralizing mechanism, an anchoring mechanism and a sealing mechanism connected in sequence from bottom to top;

[0028] The reversing righting mechanism is composed of a lower joint 13, a guide center pipe 12, a guide pin 17, a guide pin carrier 11, a righting block 16, a righting block carrier 10 and a spring 9. The upper end of the lower joint 13 is connected with the lower end of the guide center pipe 12 connection, the outer wall of the lower end of the guide central tube 12 is provided with a "W" type reversing shallow g...

Embodiment 2

[0043]On the basis of Example 1, the working process of the compression-type bottom seal packer is as follows: the setting method of the packer is compression type, which is set by lifting up and down, and then lifting and unsealing.

[0044] Setting process:

[0045] When the packer enters the well, the guide pin 17 is located at the short track (point D) of the reversing shallow groove. At this time, the cone 6 is not in contact with the slips 15, and the packer will not be anchored. When it is lowered to the predetermined setting depth , lift the pipe string by 0.3m ~ 0.4m, and then lower the pipe string, the guide pin 17 will be located at the long track (point A) of the reversing shallow groove, the slips will be stretched and bit the casing wall, and 10 ~ 35kN will be applied The down pressure (reduction of the hanging weight of the pipe string wellhead) makes the inner center rod 1 of the packer compress the inner rubber tube 2 downward, and the inner center rod 1 pushe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com