Energy accumulator tank extrusion die

A technology of extrusion dies and accumulators, which is applied to household appliances, manufacturing tools, and other household appliances, can solve problems such as inconsistent upper and lower apertures, unbalanced upper and lower pressures, bending and deformation of cup-shaped blanks 100b, etc., and achieve the completeness of upper and lower apertures. Consistent, prevent bending deformation, ensure the effect of coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

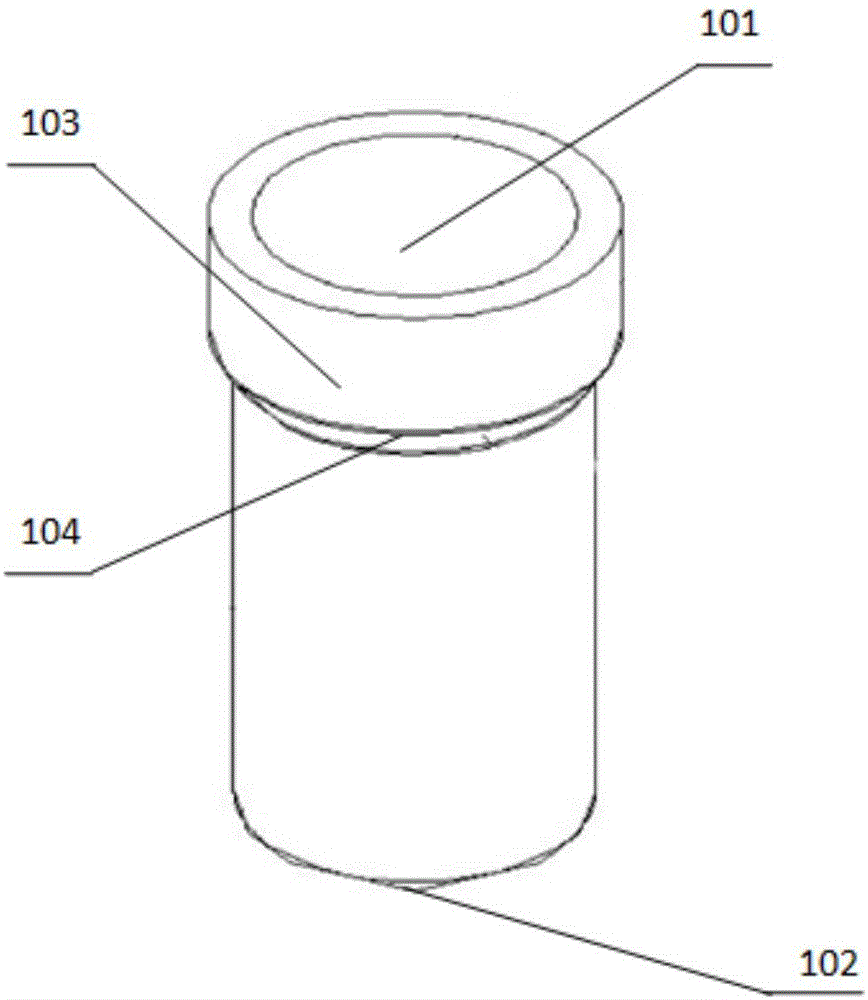

[0022] See attached figure 2 and attached Figure 4 , with figure 2 It shows the product shape change diagram of the blank of the accumulator tank body in the extrusion process, with Figure 4 Shows the accumulator tank body extrusion die and the accessory of the present invention figure 2 The assembly drawing of the cup-shaped blank 100b in .

[0023] as attached Figure 4 As shown, the accumulator tank body extrusion die of the present invention includes a punch seat 302; a punch 301, the punch 301 is arranged below the punch seat 302, and the punch 301 includes a ring 3011 and the punch core 3012 that is installed in the inner cavity of the annular punch 3011, the upper end of the annular punch 3011 is fixedly connected...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap