Multifunctional boiler

A multi-functional boiler technology, applied in steam boilers, steam boiler accessories, steam boiler components, etc., can solve the problems that the angle and length of the supporting legs cannot be changed, the installation of the boiler is not stable enough, and the actual effect is not ideal. fit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

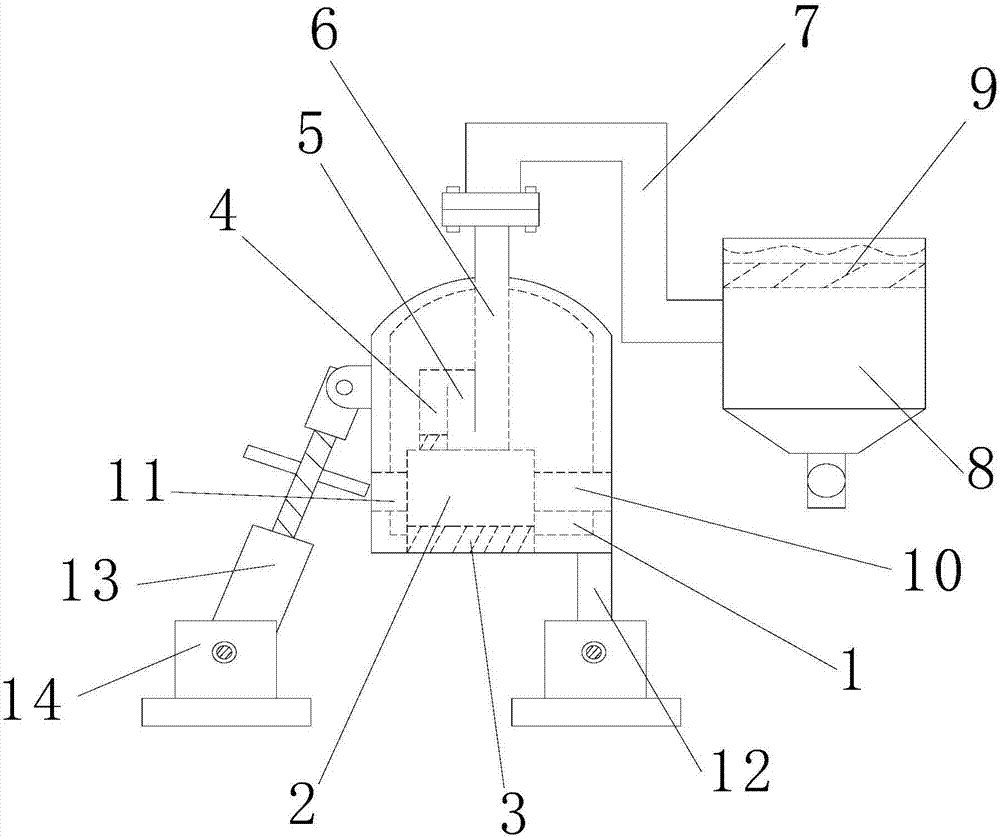

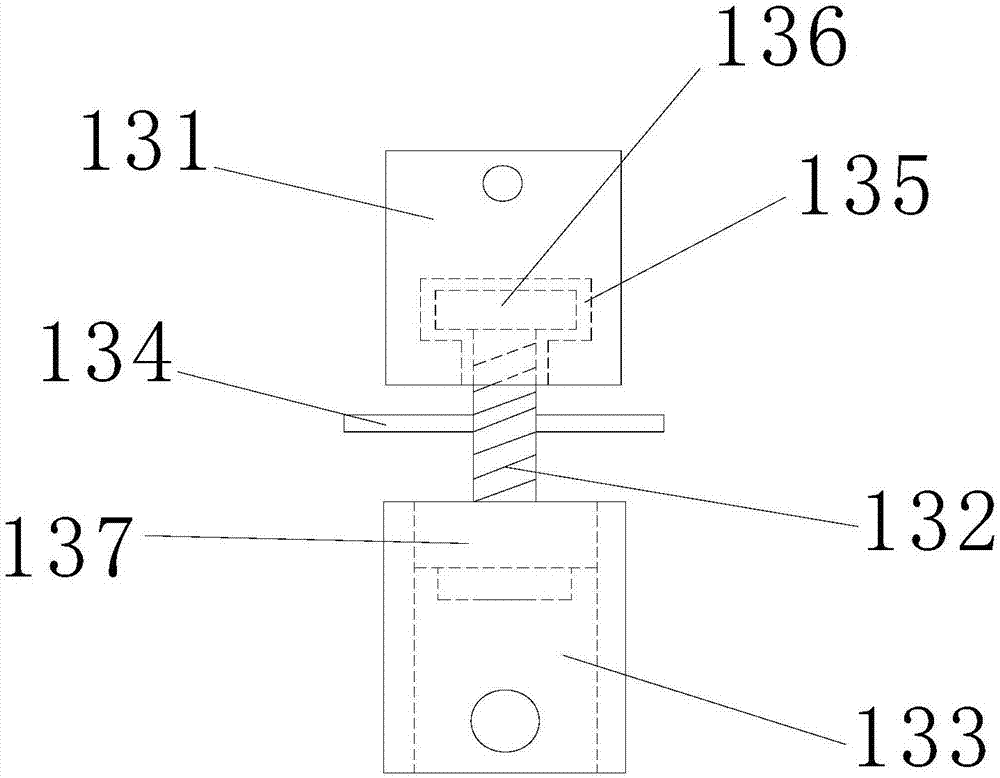

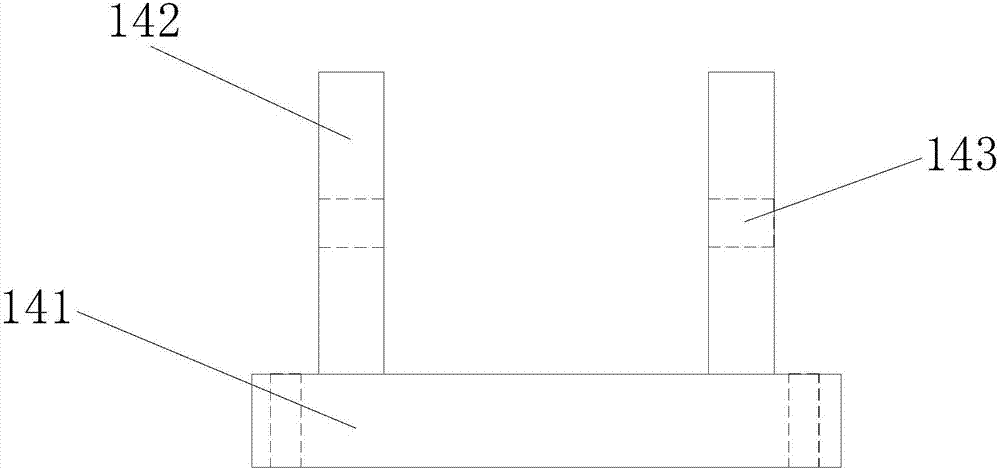

[0018] refer to figure 1 , 2 And 3, a kind of multifunctional boiler of the present invention, comprises water tank 1, combustion chamber 2, fire grate 3, ascending flue gas pipe 4, descending flue gas pipe 5, chimney 6, diversion pipe 7, water tank 8, filter screen 9 , coal feeding pipe 10, carbon slag pipe 11, support leg 12, regulating leg 13 and base 14, the bottom of the bottom of the water tank 1 is fixedly provided with a combustion chamber 2, and the bottom of the combustion chamber 2 is provided with a fire grate 3 The upper end of the combustion chamber 2 is communicated with an upward flue gas pipe 4, the upper end of the downward flue gas pipe 5 is communicated with the upper end of the downward flue gas pipe 4, and the lower end of the downward flue gas pipe 5 is connected with a chimney 6. The upper end of the chimney 6 extends to the outside of the upper part of the water tank 1, and the outer end of the chimney 6 is communicated with a guide tube 7, and the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com