A casing oiling device for stepping motor oiling

A stepper motor and oil injection device technology, applied in mechanical equipment, engine components, lubricating oil control valves, etc., can solve the problems of reducing production efficiency, increasing labor costs, too much or too little oil injection, and improving production efficiency. , The effect of improving product quality and uniform oil injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

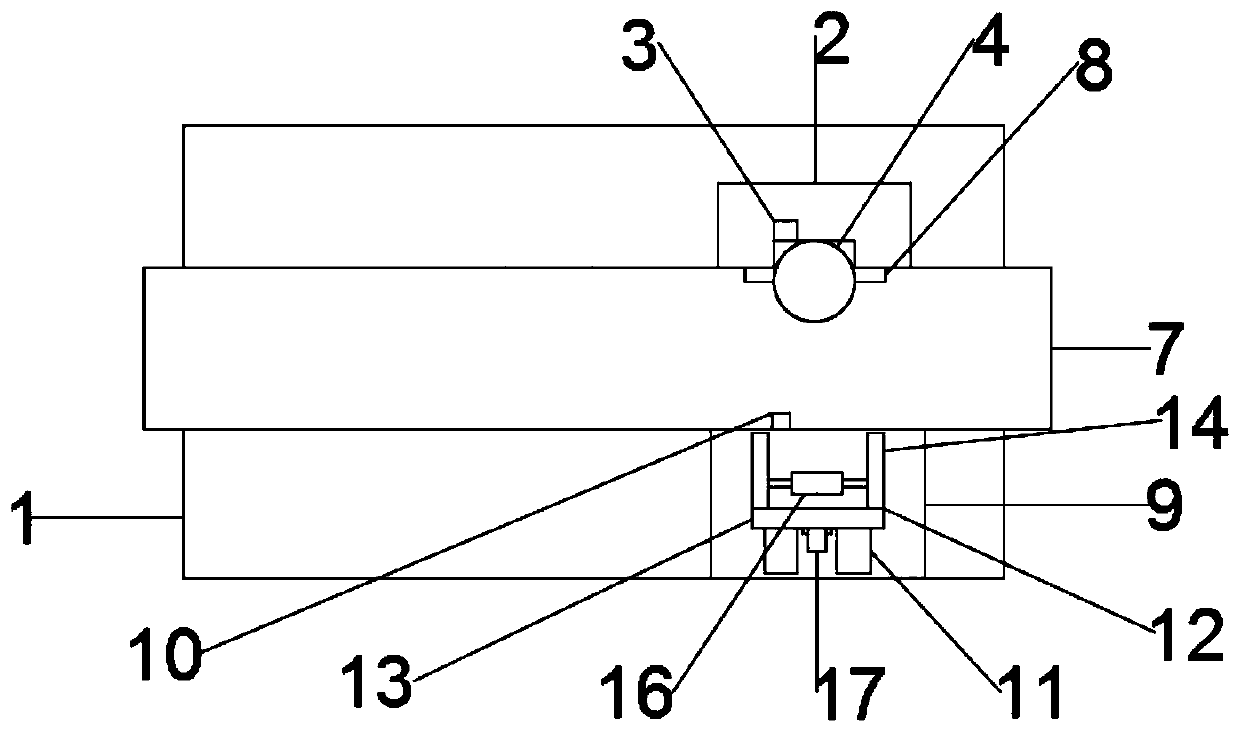

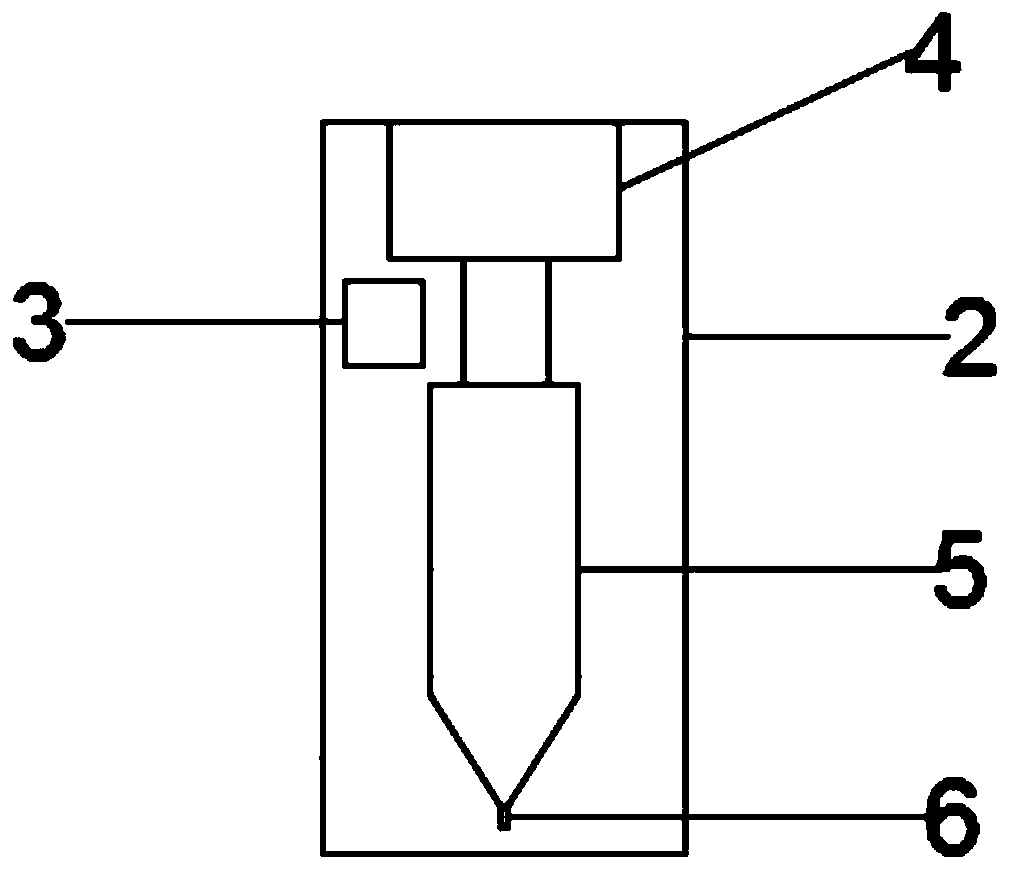

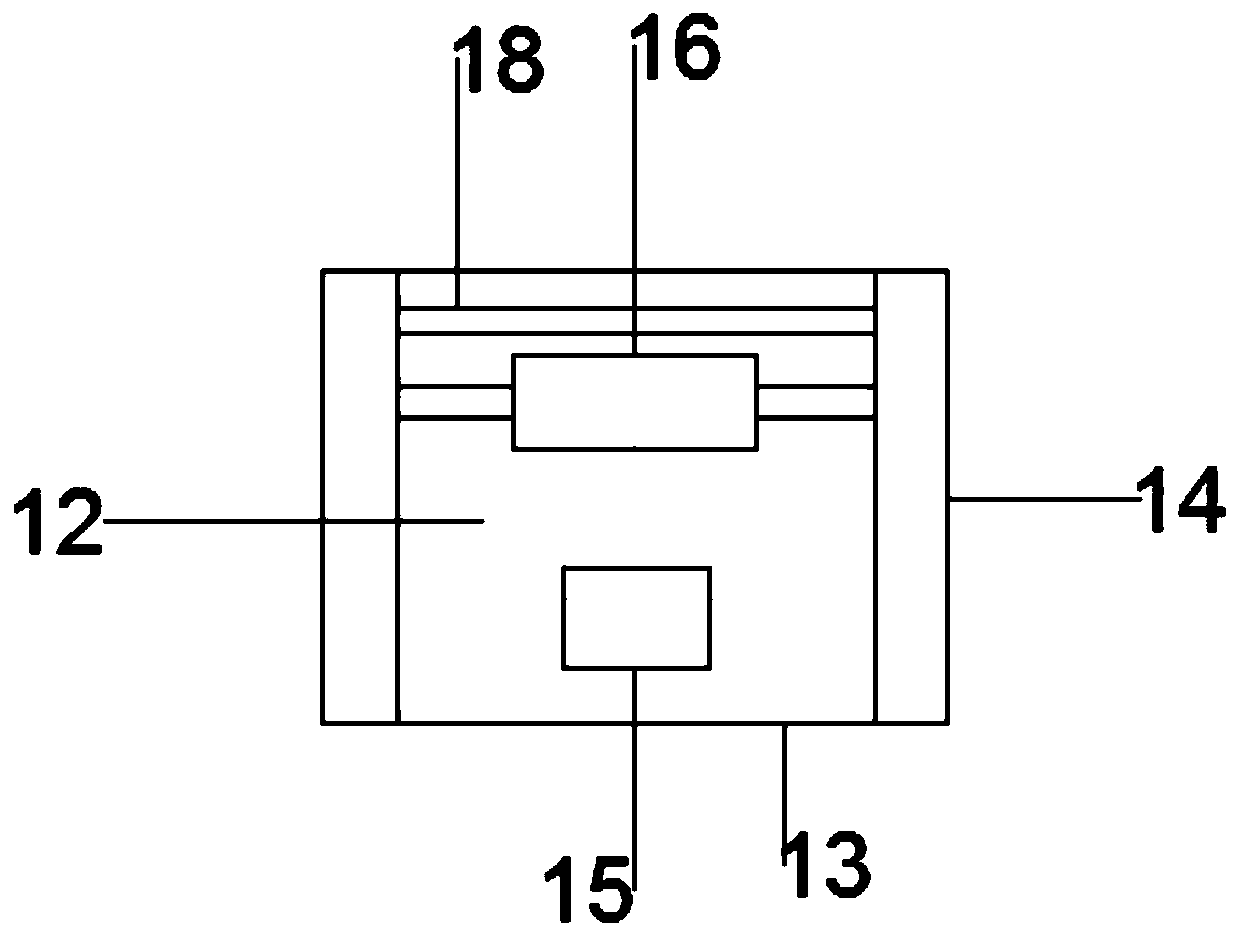

[0022] Such as Figure 1 to Figure 5 As shown, the present invention provides a technical solution, including a workbench 1, an oil injection support 2 is fixedly installed on the workbench 1, an oil injection cylinder 4 is arranged on the upper end of the oil injection support 2, and an oil injection cylinder 4 is arranged on the lower end of the oil injection cylinder 4. An oil injection pipe 5 is provided, the end of the oil injection pipe 5 is provided with an oil injection nozzle 6, a conveyor belt 7 is provided below the oil injection bracket 2, and a baffle 8 is provided on one side of the conveyor belt 7, and the baffle 8 is opposite to the conveyor belt. The stepping motor casing on the 7 and the limiter arm 14 of the limiter 12 have the effect of limiting, so that the grease nozzle 6 can just be vertically opposite to the casing to improve the machining accuracy. The other side of the conveyor belt 7 is provided with limited Positioner bracket 9, said limiter bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com