A high temperature pipeline protection device

A protection device and pipeline technology, applied in the direction of pipeline supports, pipe elements, pipes/pipe joints/pipe fittings, etc., can solve the problems of high cost, high cost, occupation of ship space resources, etc., and achieve protection against impact damage, easy installation, and economical The effect of ship space resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

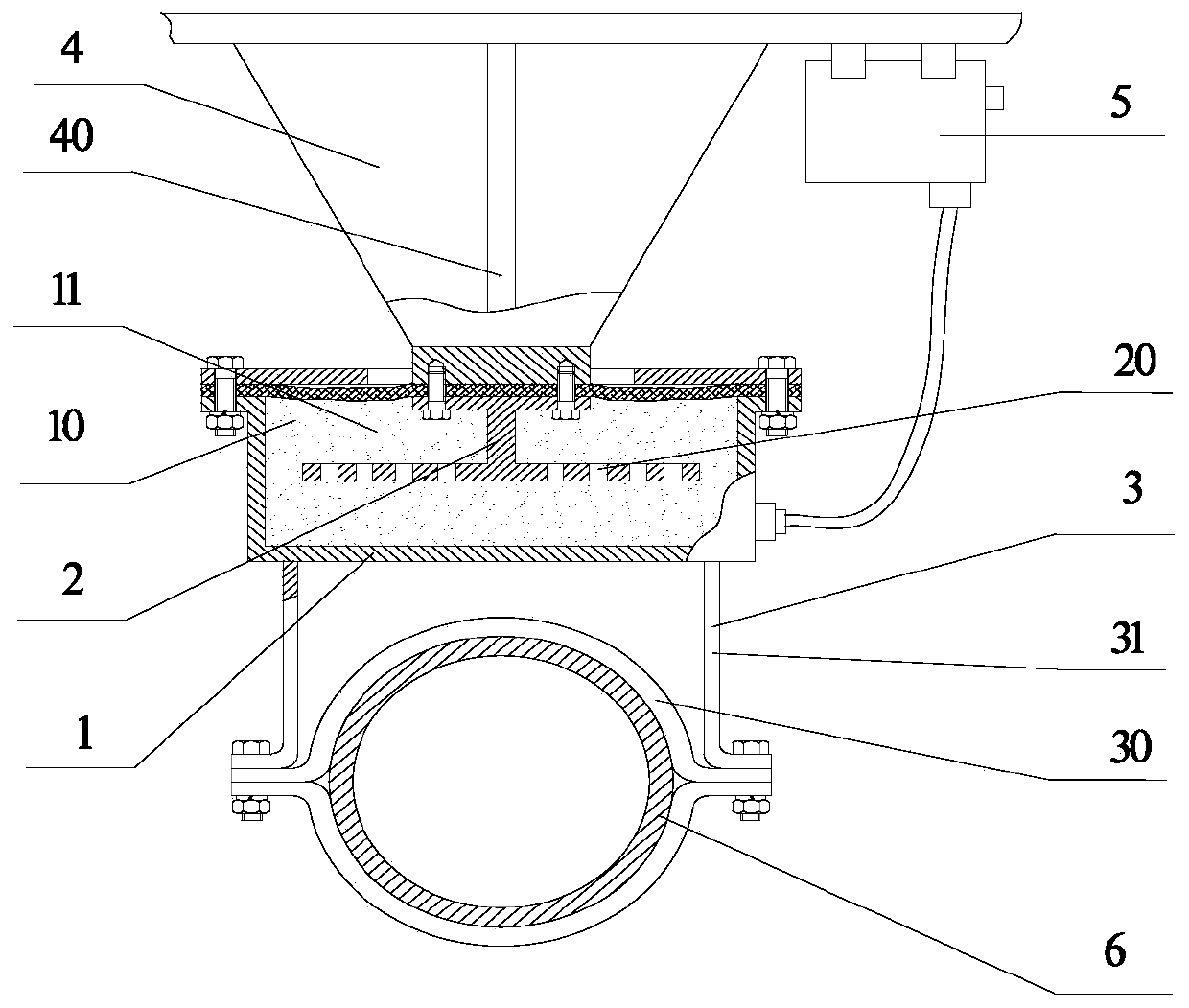

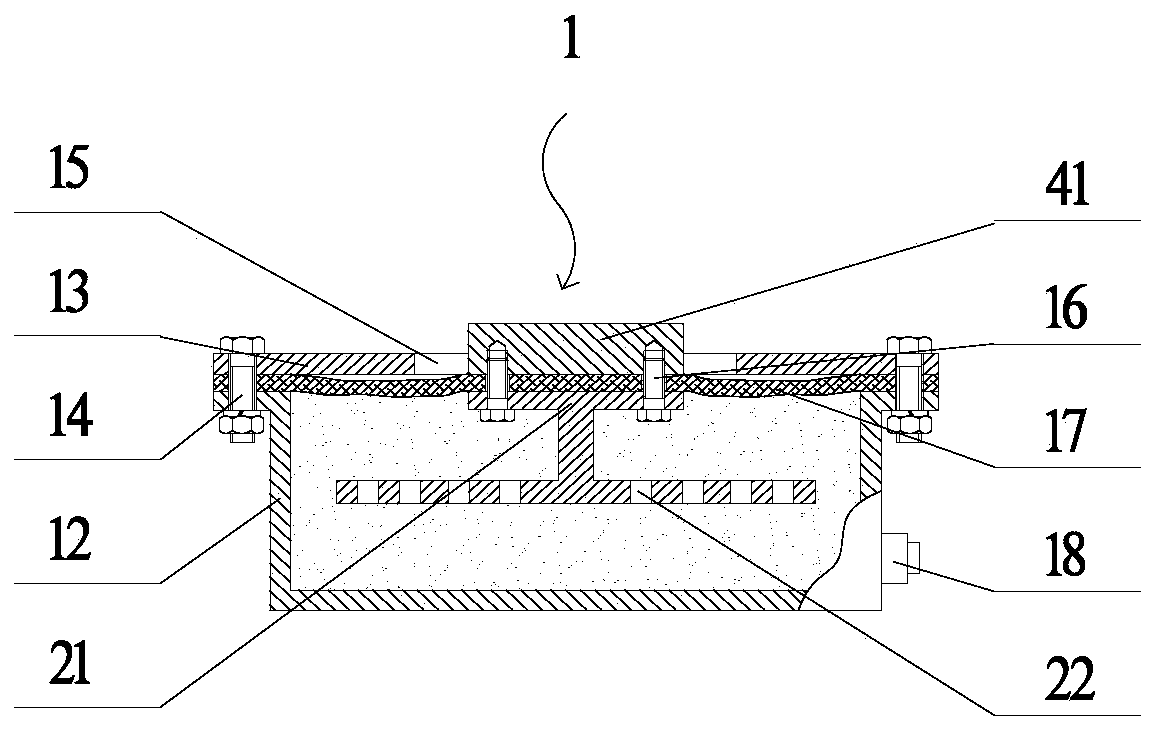

[0025] see figure 1 As shown, the embodiment of the present invention provides a high-temperature pipeline protection device, which includes a casing 1 , and the casing 1 includes a casing body 12 and a casing cover 13 assembled on the casing body 12 . The central region of the housing cover 13 is provided with a cover opening 15 . The top of the shell body 12 extends outward to form a convex edge, and the shell cover 13 is fixed on the convex edge by bolts. The space surrounded by the housing body 12 and the housing cover 13 is a storage space 10 , and the storage space 10 is filled with particles 11 .

[0026] The pipeline protection device also includes an energy-absorbing member 2 , a plate body 22 of the energy-absorbing member 2 is embedded in the particulate matter 11 , and a plurality of small holes 20 are evenly distributed on the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com