A method for exfoliating two-dimensional materials

A two-dimensional material, bulk technology, applied in the field of two-dimensional material exfoliation, can solve the problem of long time and achieve the effect of short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 6

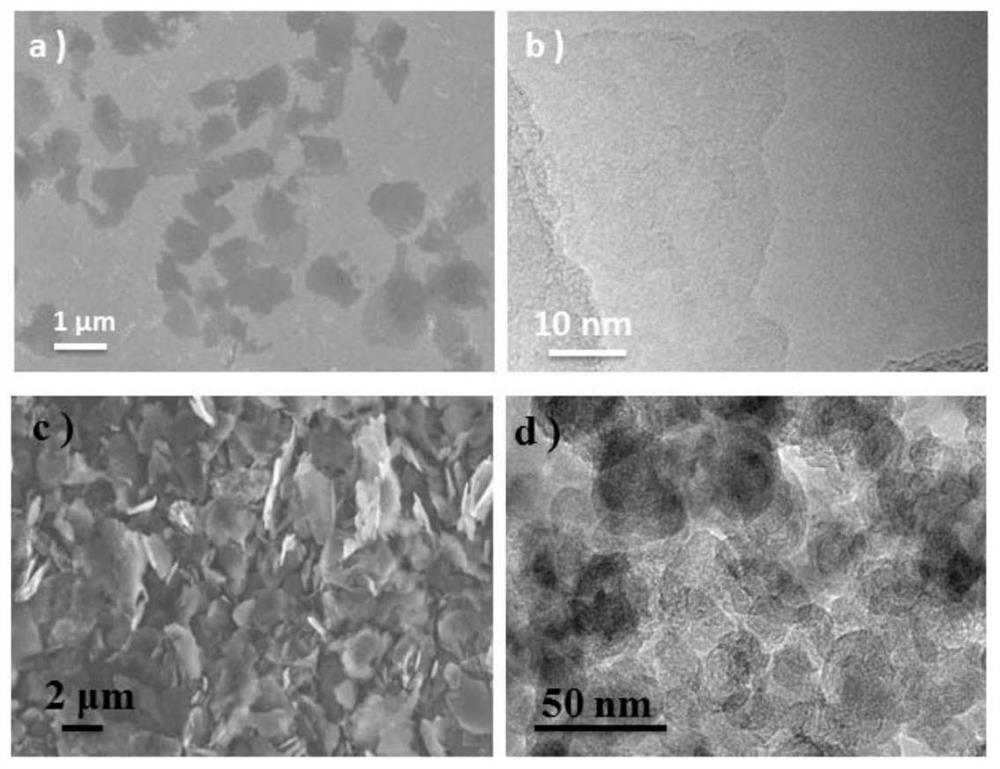

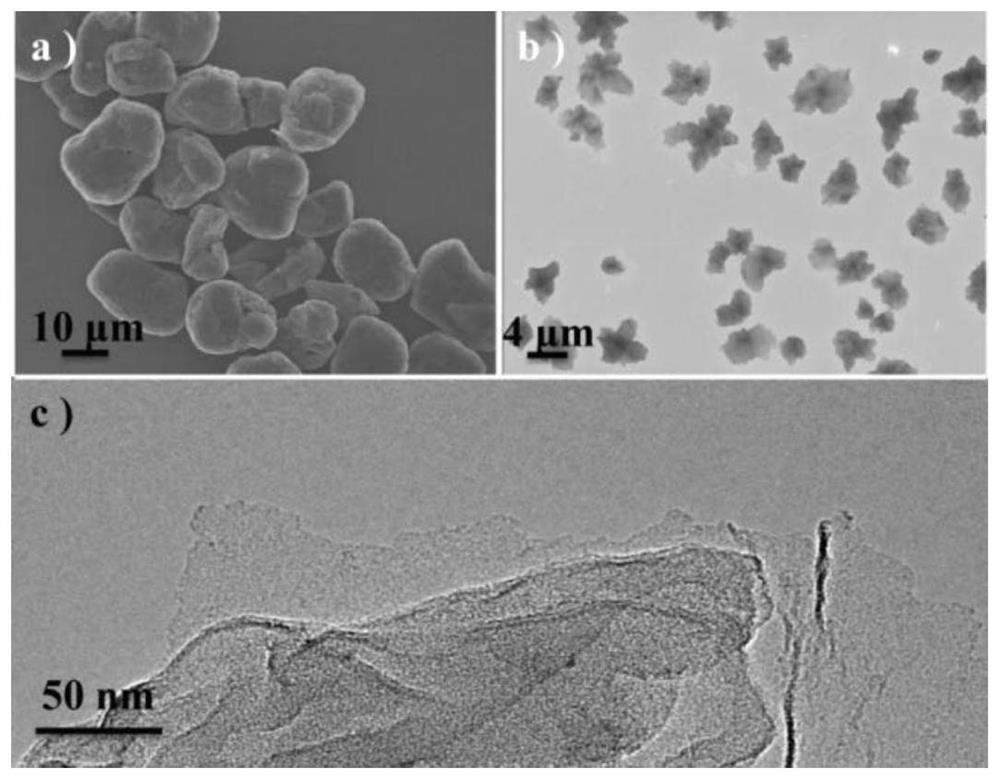

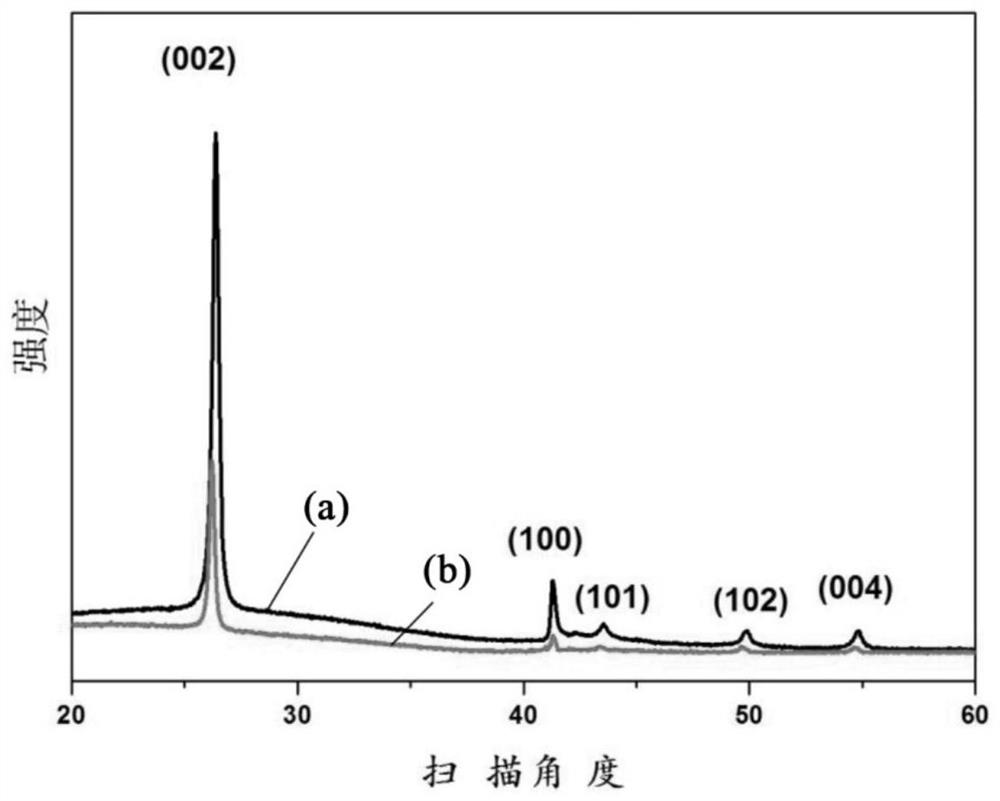

[0040] The stripping of embodiment 1 hexagonal boron nitride

[0041]After heating 0.5 g of commercial block hexagonal boron nitride (hexagonal boron nitride powder) to 800°C, it was directly put into 50 mL of ice-water mixture, ultrasonicated for 30 minutes, and then freeze-dried.

Embodiment 2 6

[0042] The stripping of embodiment 2 hexagonal boron nitride

[0043] Heat 0.5g of commercial block hexagonal boron nitride (hexagonal boron nitride powder) to 900°C, put it directly into 50mL of ice-water mixture, ultrasonicate for 30 minutes, and then freeze-dry;

[0044] After the freeze-dried product was heated to 900°C, it was directly put into 50 mL of ice-water mixture, ultrasonicated for 30 minutes at the same time, and then freeze-dried.

Embodiment 3 6

[0045] The stripping of embodiment 3 hexagonal boron nitride

[0046] Heat 0.5g of commercial block hexagonal boron nitride (hexagonal boron nitride powder) to 900°C, put it directly into 50mL of ice-water mixture, ultrasonicate for 30 minutes, and then freeze-dry;

[0047] After heating the freeze-dried product to 900°C, put it directly into a 50mL ice-water mixture, ultrasonicate for 30 minutes at the same time, and then freeze-dry;

[0048] After the second freeze-dried product was heated to 900°C, it was directly put into 50 mL of ice-water mixture, ultrasonicated for 30 minutes, and then freeze-dried.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com