A container crane for U-shaped berth

A container crane and container technology, which is applied in the direction of cranes, cranes, and traveling mechanisms of trolleys, can solve the problems of restricted area switching, low transportation efficiency, and large investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

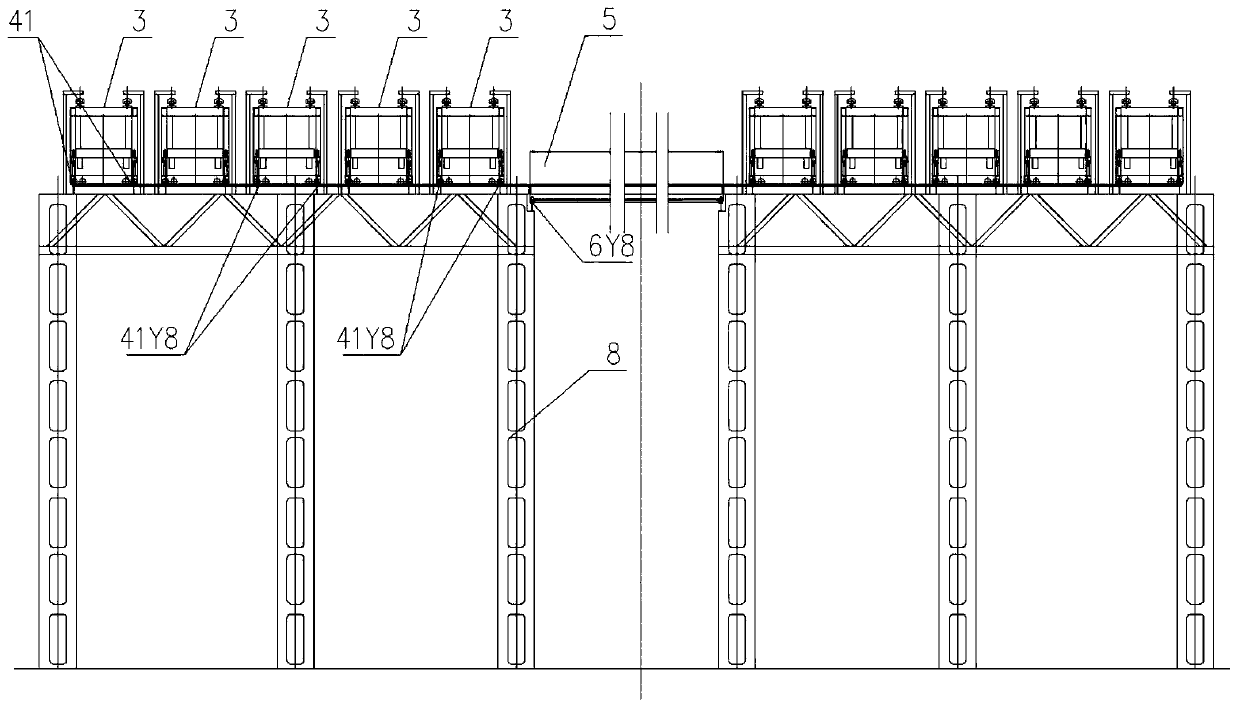

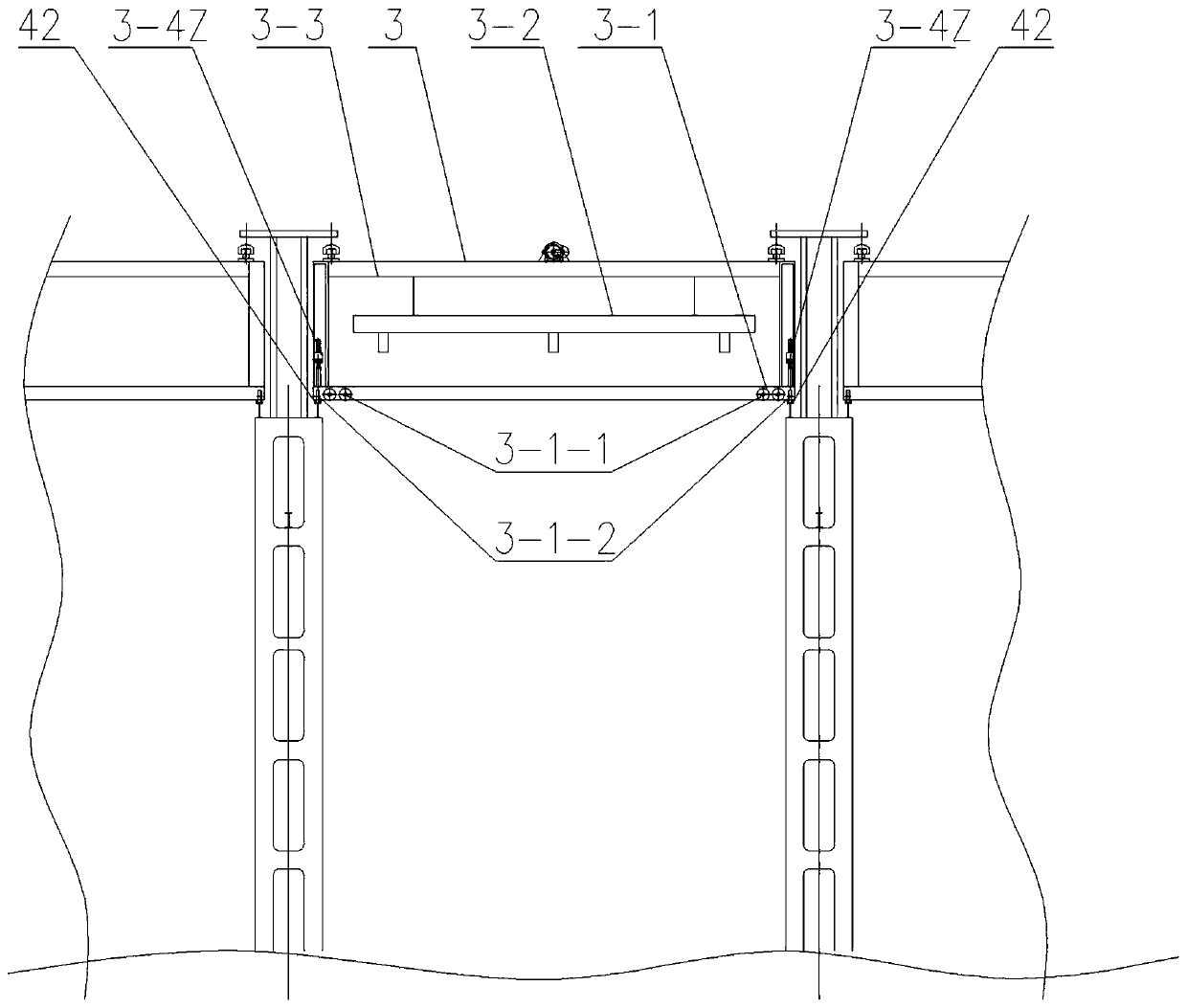

[0047] The container crane 1 includes the transport trolley 3 of the container 2, the track 4 on which the transport trolley 3 runs, the cart 5, the track 6 on which the cart 5 runs, the U-shaped berth 7 and the components 8 on the U-shaped berth 7; the U-shaped berth 7 The length direction of the bottom edge is the X direction, the length of the bottom edge 7X is greater than the width of the container ship 9, the length of the vertical edge 7Y of the U-shaped berth 7 is greater than the length of the ship 9, and the length direction of the container 2 on the ship 9 is parallel to that of the ship 9. In the length direction, when the ship 9 is berthed in the U-shaped berth 7, the length direction of the ship 9 is the Y direction; the member 8 near the ship 9 on the vertical side 7Y is provided with a cart 5 running along the Y direction. The cart Y track 6Y8 , the middle of the upper member 8 on the vertical side 7Y is provided with the longitudinal Y track 41Y8 of the transpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com