Conveying device used for railway vehicle maintenance and production

A technology for conveying devices and railway vehicles, which is applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., which can solve the problems of incomplete coverage of the conveying area and difficulty in automation, so as to achieve automatic operation, easy automatic operation, and full coverage The effect of logistics delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

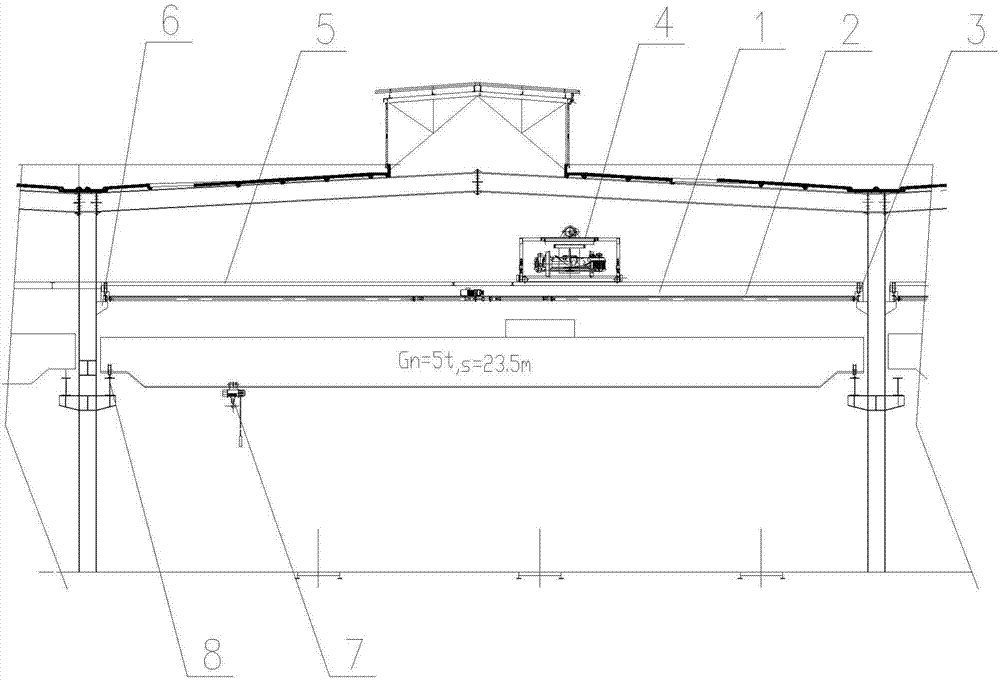

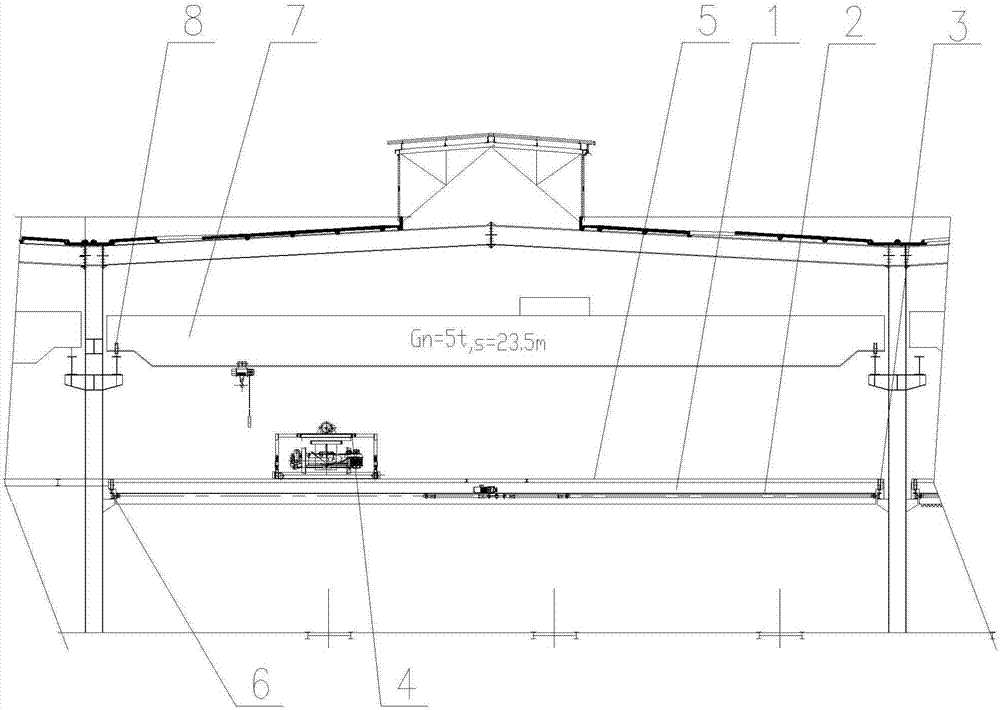

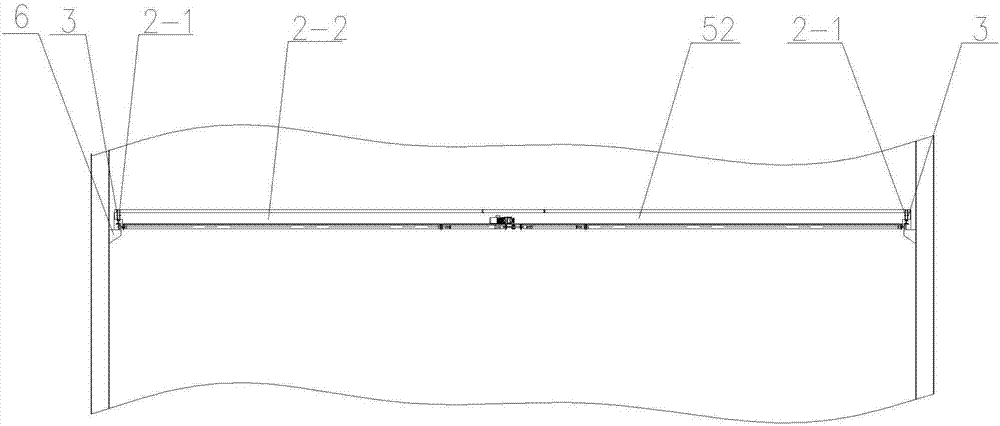

[0027]Conveying device 1 comprises carrying trolley 2, the aerial rail 3 that carrying trolley 2 moves, load trolley 4, the running track 5 of load trolley 4, column member 6, driving 7 and the track 8 that driving 7 moves, the length of track 3 is established The direction is the X direction; the carrying trolley 2 includes a running device 2-1, a frame 2-2 and a track 52 on which the loading trolley 4 runs, and the running device 2-1 is fixed on both ends of the frame 2-2, and the running device 2-1 Walking on the track 3, the track 3 is fixed on the component 6, the loading trolley 4 includes a running device 4-1, a lifting device 4-2 and a frame 4-3, and the running device 4-1 is located at the bottom of the frame 4-3, Lifting device 4-2 is positioned at the top of frame 4-3, and frame 4-3 is the cavity of bottom opening, and the hook device 4-3-1 of lifting device 4-3 lifts the article below frame 4-3 to In the cavity of the frame 4-3, the bottom surface of the article is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com