Railway container yard and conveying device thereof

A technology of conveying device and container, applied in the direction of conveyor, storage device, mechanical conveyor, etc., can solve the problems of low degree of automation, low efficiency, container loading and unloading, slow transfer speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

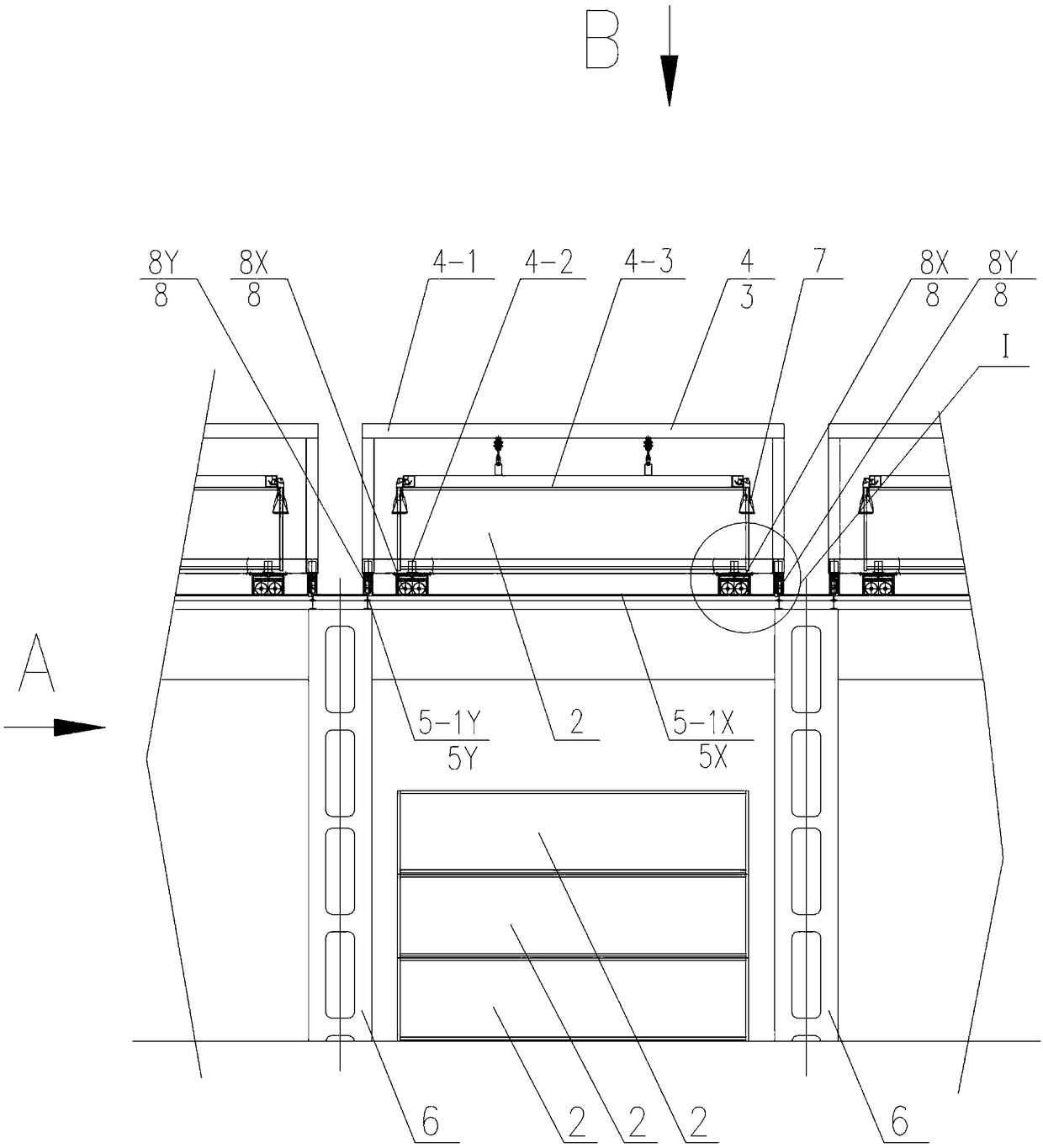

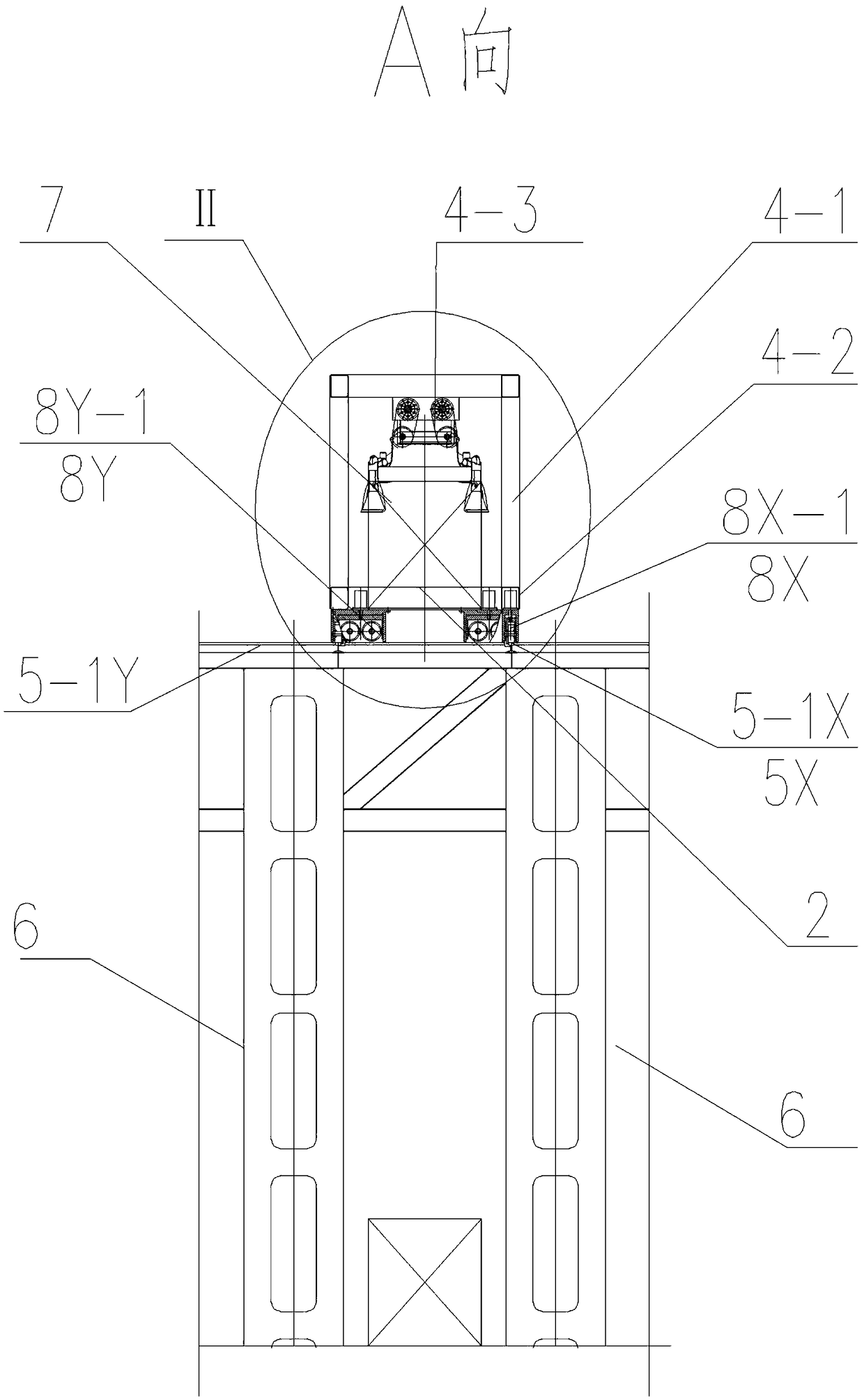

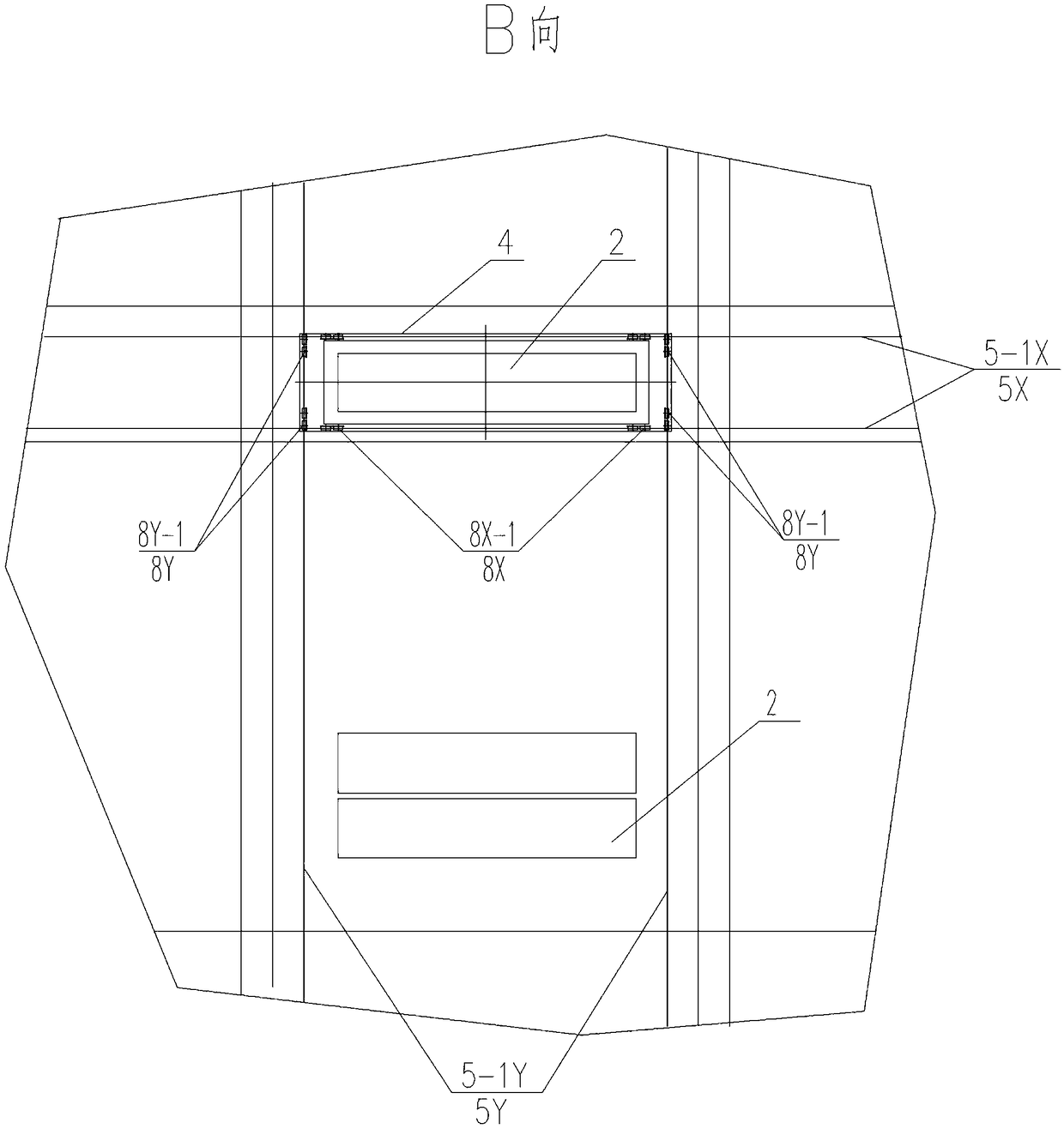

[0052]The conveying device 3 of the container 2 in the railway container yard 1 includes the container transport vehicle 4, the freight yard track 5 and the column member 6 that the transport vehicle 4 runs, and the length direction of the railway track in the freight yard 1 is the X direction, and the length direction of the transport vehicle 4 is is the length direction of the container 2, the width direction of the transport vehicle 4 is the width direction of the container 2, and the transport vehicle 4 includes a frame 4-1, a jacking switching device 4-2, a lifting device 4-3, a suspension device 7 and a walking Device 8, the frame 4-1 is a cavity with an opening at the bottom, the traveling device 8 is located at the bottom of the frame 4-1, the lifting device 4-3 is located at the top of the frame 4-1, and the lifting device 4-3 passes through the hanging device 7 Hang the container 2 under the frame 4-1 into the frame 4-1, or place the container 2 in the frame 4-1 under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com