Rubber belt winding machine

A technology of winding machine and rubber belt, which is applied in the directions of winding strips, thin material processing, transportation and packaging, etc., and can solve problems affecting the performance of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

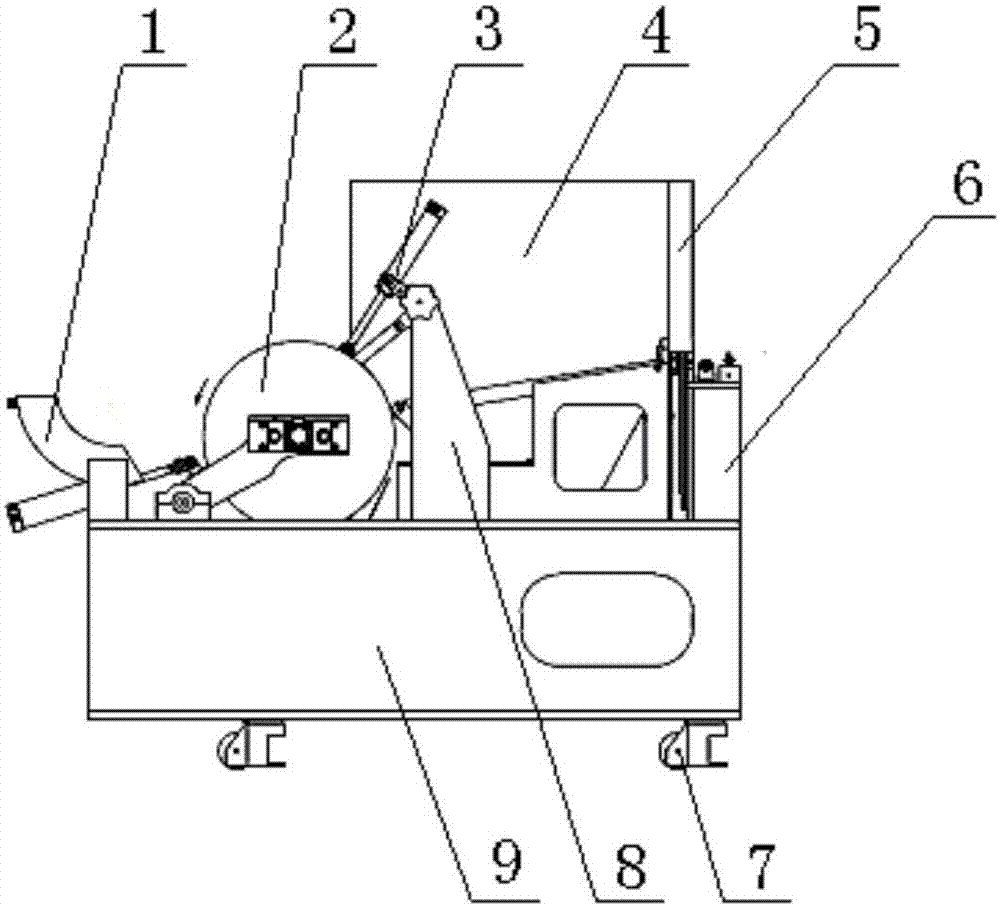

[0012] Such as figure 1 , figure 2 As shown, a rubber belt winding machine includes a base 9, a feeding mechanism 6, a power mechanism, a roll changing bracket 1, a winding mechanism 2, a pressing mechanism 3 and a cutting mechanism 5, and the feeding mechanism 6 is located at the base 9 On the upper side, the roll change bracket 1 is located on the other side above the base 9, and there are a cutting mechanism 5, a winding mechanism 2 and a pressing mechanism 3 between the feeding mechanism 6 and the roll change bracket 1, and the cutting mechanism 5 is located The side of feeding mechanism 6, the side of feeding mechanism 6 has cutting mechanism connection bracket 13, and there is pressing mechanism connection bracket 8 above the base middle part, and base 9 is also linked to each other with control cabinet 4. Cutting mechanism 5 comprises circular knife rest 11, the ratchet 12 that drives circular knife rest 11 to rotate and three cutting blades 10 that are evenly distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com