Elevator

A hoist and casing technology, which is applied in the field of material hoists, can solve the problems of short service life, easy wear and tear of machinery, inability to automatically dig and discharge materials, etc., and achieve the effect of preventing dust from flying and stabilizing the conveying process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention, and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

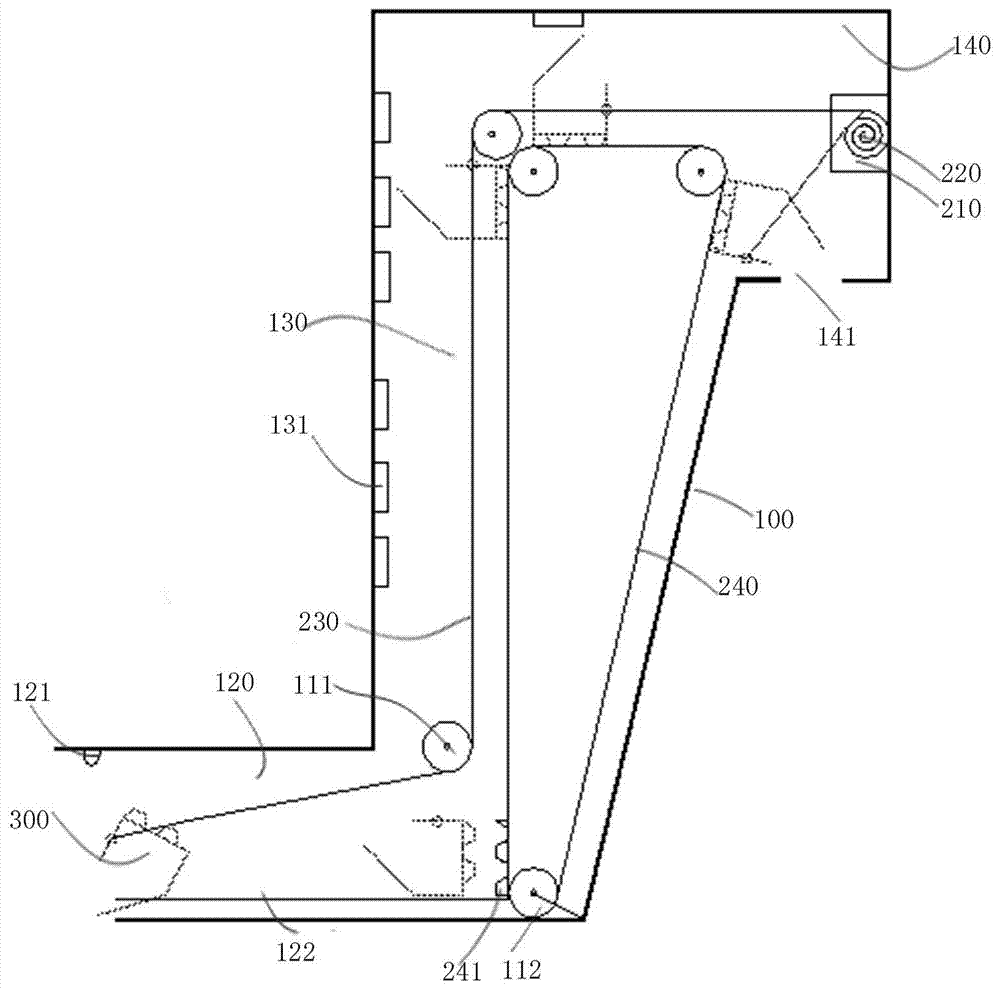

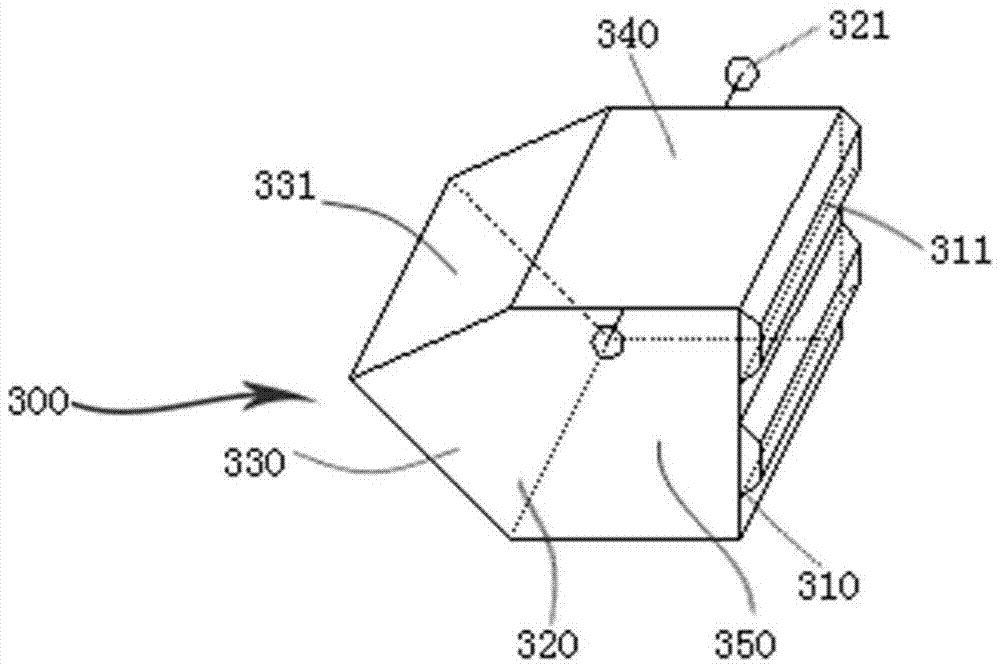

[0025] a hoist, such as figure 1 As shown, this hoist is used to lift materials to a high place to facilitate subsequent process operations. This hoist includes: a casing 100 , and a power assembly 200 and a hopper 300 installed in the casing 100 .

[0026] The inner space of the casing 100 forms a channel 110 , and traction pulleys 111 and crawler pulleys 112 are installed on both sides of the channel 110 for guiding the operation of the power assembly 200 .

[0027] The channel 110 includes a horizontal feed channel 120, a vertical lifting channel 130 and a horizontal discharge channel 140 from bottom to top. The top surface of the feed channel 120 has a steam spray gun 121, which can spray high-temperature water vapor to wet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com