Condenser pipe arrangement spot welding machine with hanging rack

A technology of condensing tubes and hanging racks, which is applied in the field of condensing tube discharge spot welding machines, which can solve the problems of large fluctuations in product quality, inconvenient operation, and slow processing speed, and achieve uniform spot welding effects, convenient fixed connections, and fast connection speeds Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

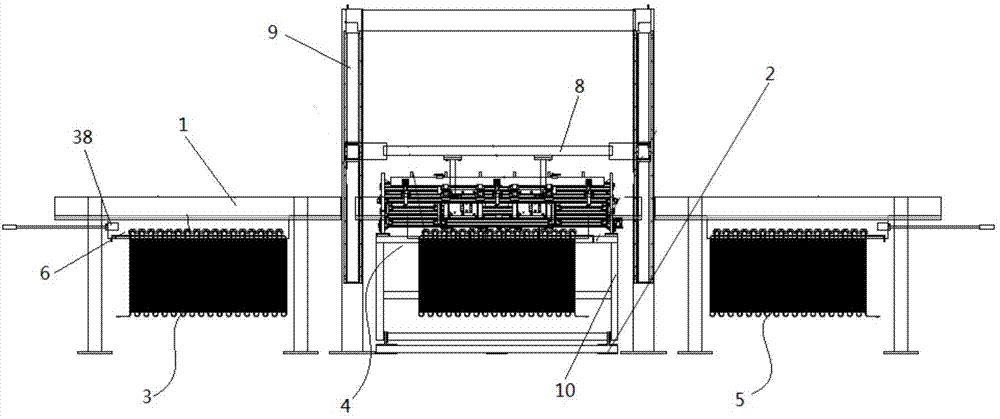

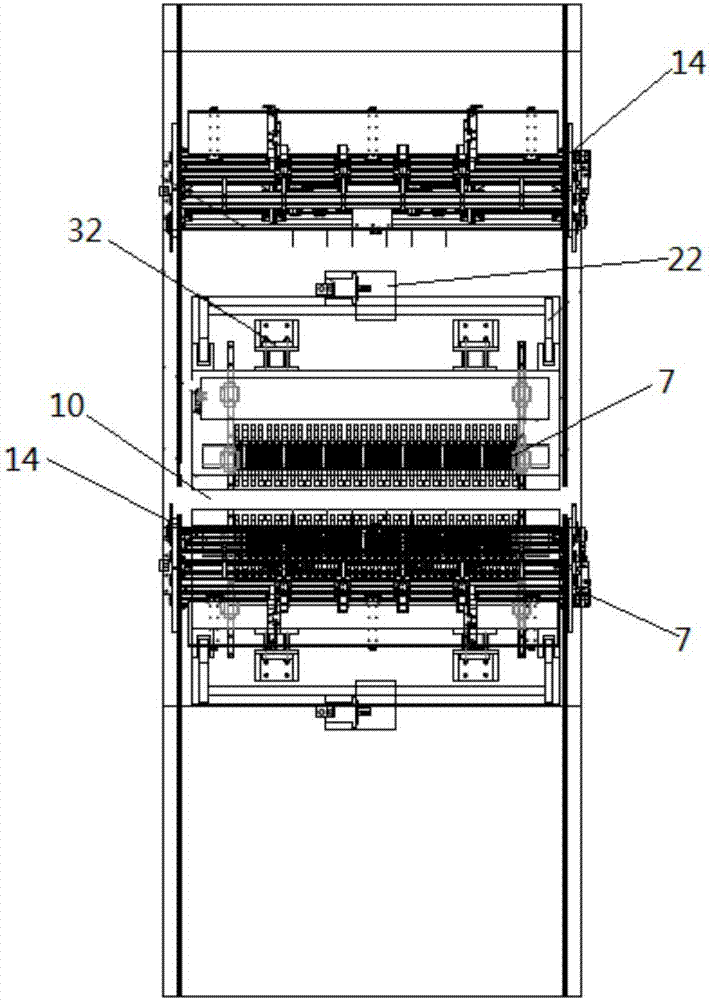

[0038] Such as Figure 1-7 As shown, this embodiment discloses a condensation tube discharge spot welder with a hanger, including a hanger mechanism 2 arranged on the X-axis track 1, and the mobile hanger mechanism 2 is sequentially moved in the direction of the X-axis track 1 A material hanging mechanism 3, a spot welding mechanism 4 and a blanking mechanism 5 are provided; the material hanging mechanism 3 includes a hanger 6; the spot welding mechanism 4 is provided with a spot welding device 7 on both sides of the X-axis track 1, and above the spot welding mechanism 4 A Y-axis lifting device 8 is provided along the Y-axis direction. The Y-axis lifting device 8 can move along the Y-axis track 9. The Y-axis lifting device 8 can be automatically connected with the hanger 6 that moves below. Welding clamping station 10; Hanger 6 can move in the spot welding clamping station 10, and spot welding clamping station 10 is evenly provided with several U-shaped draw-in grooves 11, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com