Pen-type solder stick electric extruding feeder

A solder wire and extrusion technology is applied in the field of pen-type solder wire electric extrusion feeders, which can solve the problems of low welding efficiency and achieve the effects of convenient use, stable and reliable wire feeding, and simple manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

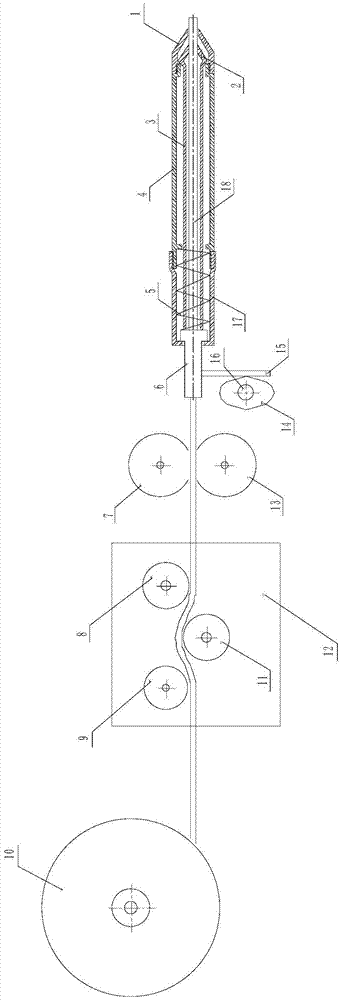

[0018] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

[0019] A pen-type solder wire electric extrusion feeder, which includes a pen tip 1, a clamping valve 2, an inner cylinder 3, a pen holder 4, a spring 5, a pressing rod 6, an upper wire feeding roller 7, an upper right straightening wheel 8, Left upper straightening wheel 9, solder wire reel 10, lower straightening wheel 11, straightening device housing 12, lower wire feeding roller 13, cam 14, push plate 15, drive motor 16 and connecting sleeve 17, the solder The wire reel 10 is installed on the rotating shaft, and the upper right straightening wheel 6 and the upper left straightening wheel 8 are installed on the straightening device housing 7 through bearings and the upper right straightening wheel 6 is located on the right side of the upper left straightening wheel 8. The lower straightening wheel 10 is installed on the straightening device housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com