Evaporative pattern casting coating and preparation method and using method thereof

A technology of lost foam casting and coating, applied in casting molding equipment, coating, mold and other directions, can solve problems such as insufficient strength, low work efficiency, cracking and even peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

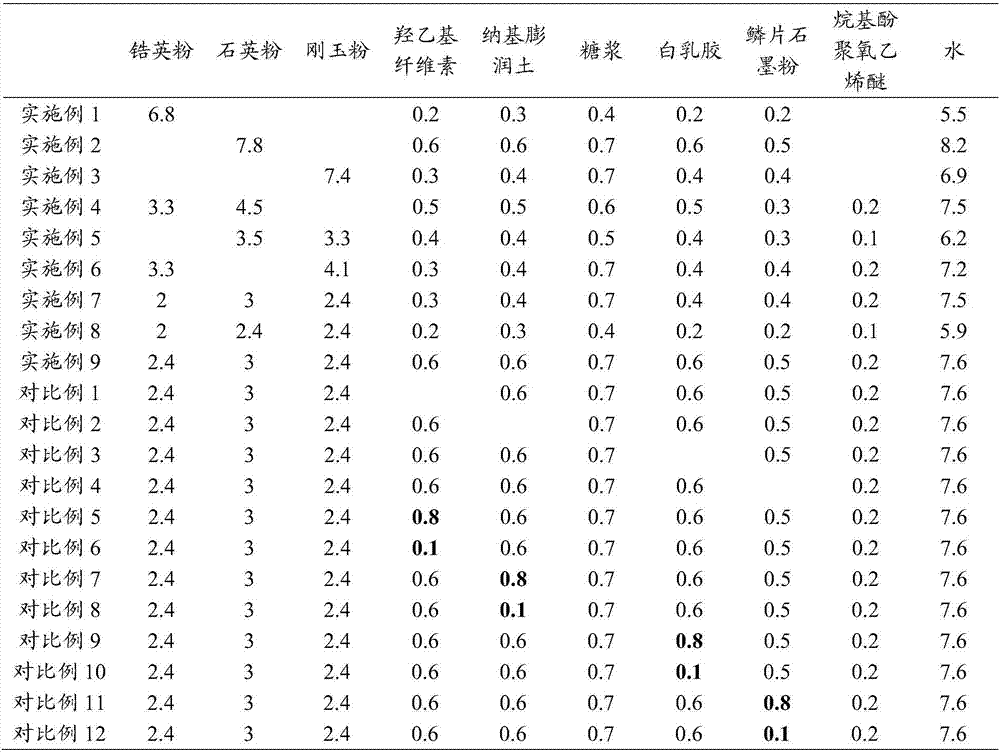

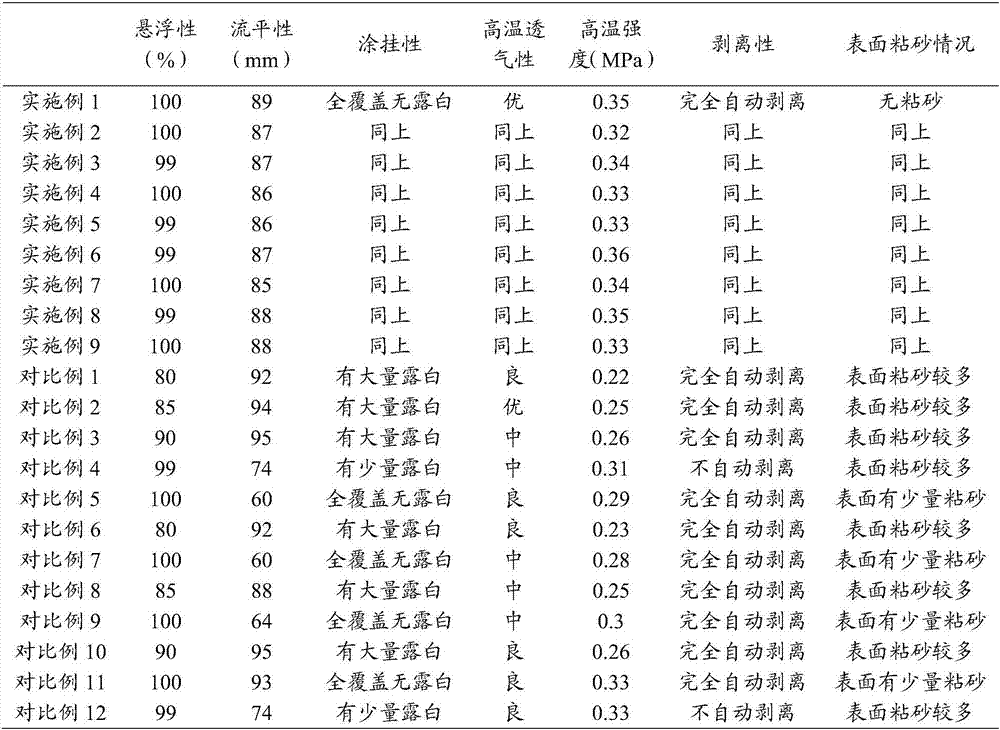

Examples

preparation example Construction

[0036] The preparation method of the lost foam casting paint is simple and quick, and the obtained lost foam casting paint has the characteristics of high strength and good stripping property in the coating formed in the lost foam casting process.

[0037] The present invention also provides a method for using the above-mentioned lost foam casting coating in an embodiment: mixing the above-mentioned lost foam casting coating with water at a weight ratio of 100:68-76, and then it can be used.

[0038] Specifically, the mixing condition is: stirring at a rotating speed of 500-600 rpm for 30-120 minutes, and then stirring at a rotating speed of 180-240 rpm for 20-40 minutes.

[0039] The applicant has found through research that factors such as water content, stirring speed and stirring time will affect various properties of the lost foam casting coating, such as high temperature strength, stripping property, suspending property, leveling property and coating property. Therefore,...

Embodiment 1

[0045] Under normal temperature and pressure, according to the composition and weight of the lost foam casting coating in Example 1 in Table 1, batching was carried out. The components are mixed and stirred thoroughly to obtain the lost foam casting coating. According to the weight of water in Example 1 in Table 1, add water to the lost foam casting coating, stir at a speed of 500 rpm for 120 minutes, and then stir for 40 minutes at a speed of 180 rpm to obtain the used lost foam casting coating . Apply the used lost foam casting paint evenly on the surface of the plastic foam model, then put the model in a 50°C drying oven to dry for 12 hours, repeat the above coating and drying steps twice, and then perform sand burying and vacuum pouring, Finally, the casting can be unpacked after cooling down.

Embodiment 2

[0047] Under normal temperature and pressure, according to the composition and weight of the lost foam casting coating in Example 2 of Table 1, batching was carried out. The components are mixed and stirred thoroughly to obtain the lost foam casting coating. According to the weight of water in Example 2 in Table 1, add water to the lost foam casting coating, stir at a speed of 600 rpm for 30 minutes, and then stir at a speed of 240 rpm for 20 minutes to obtain the used lost foam casting coating . Subsequent steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com