A kind of preparation method of transition metal modified silicalite catalyst

A technology of stevensite and transition metal, which is applied in the field of preparation of transition metal-modified ferrierite catalyst, can solve the problems of high cost and easy deactivation of the catalyst, and achieves the advantages of reducing production cost, solving easy deactivation and facilitating popularization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] a. Weigh 0.602g of magnesium sulfate, add 9.0g of deionized water, the molar ratio of magnesium sulfate to water is 1:100, add 5g of 98% concentrated sulfuric acid, stir at room temperature for 0.5h to obtain a uniform solution of magnesium sulfate and sulfuric acid a.

[0027] b. Weigh the silicon source water glass Na 2 SiO 3 •9H 2 O 71.125g, add 90g deionized water, the molar ratio of water glass and water is 1:20, stir at room temperature for 0.5h, form a uniform solution, and obtain solution B.

[0028] c. Under vigorous stirring at a speed of 150r / min, slowly drop the mixed solution A of the previous step into the solution B of this step, and at the same time add 11.518g of ethanol as a template agent, and the molar ratio of the template agent to water glass is 1:1. After stirring for 2h, a homogeneous solution C was obtained.

[0029] c. Stir the solution C for 0.5 h with a high-speed shear emulsifying glue maker, and put the obtained gel into a polytetraflu...

Embodiment 1

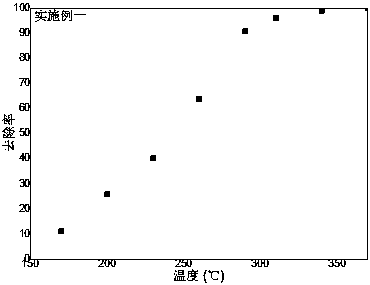

[0034] The catalyst activity test figure of embodiment 1 is as figure 1 It can be seen from the figure that the T50 (the temperature at which the conversion rate of toluene is 50%, the same below) for the catalytic degradation of toluene by the catalyst is 240°C, and the T90 is 289°C. The catalyst has good catalytic activity for catalytic degradation of toluene.

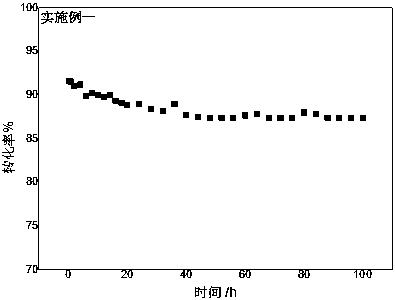

[0035] The catalyst activity test figure of embodiment 1 is as figure 1 As mentioned above, it can be seen from the figure that the experimental results of the catalytic life of the catalyst for 100 hours. The experimental condition is that the intake air velocity is 10000h -1 , the intake toluene concentration is 1000ppm, and the catalytic temperature is 300°C. It can be seen from the figure that the catalytic activity of the catalyst does not change much after 100 hours of continuous catalysis, and the catalytic efficiency drops by 4.5%, so the catalyst has good catalytic stability.

Embodiment 2

[0037] a. Weigh 0.602g of magnesium sulfate, add 8.1g of deionized water, the molar ratio of magnesium sulfate and water is 1:90, add 5g of 98% concentrated sulfuric acid, stir at room temperature for 0.5h, and obtain a uniform mixed solution of magnesium sulfate and sulfuric acid a.

[0038] b. Weigh 142.250g of water glass Na2SiO3•9H2O, add 270g of deionized water, the molar ratio of water glass to water is 1:30, stir at room temperature for 0.5h, and form a uniform solution solution B.

[0039] c. Under vigorous stirring, at a speed of 150r / min, slowly add solution A to solution B, and simultaneously add 32.045g of methanol as a template agent, the molar ratio of template agent to water glass is 1:0.5, stir for 3h, A homogeneous solution C was obtained.

[0040] d. Stir the solution C for 0.5 h with a high-speed shear emulsifying glue maker, put the obtained gel into a polytetrafluoroethylene-lined hydrothermal crystallization kettle for 24 h to crystallize, and the crysta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com