Method for preparing herbicide from starch wastewater

A technology for starch wastewater and herbicides, applied to herbicides and algicides, methods based on microorganisms, botanical equipment and methods, etc., can solve the problems of undiscovered herbicides, difficulty in large-scale use, and high price, and achieve Facilitate large-scale production, promote the utilization of nutrients, and improve the effect of growth ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing herbicides using starch wastewater, including the following steps:

[0029] 1) Wastewater conditioning: Mix fish scale meal and earthworm feces at a weight ratio of 1:5, and let them stand for 24 hours under indoor ventilation to obtain the first mixture. Mix the first mixture with starch wastewater at a weight ratio of 1:8 Place it in a stirring tank, and stir for 30 minutes at a stirring rate of 10r / min every 3.5h under indoor ventilation, and adjust the pH to 7.0 after 48h to obtain the second mixture;

[0030] 2) Seed preparation: Sterilize and cool the second mixture and inoculate the original Streptomyces erythraea. The inoculation concentration of the original Streptomyces erythropolis is 10 per ml of the sterilized second mixture. 6 Spores were cultured in a shake flask at 28-30°C at 150r / min for 36 hours to obtain liquid seeds. The strain number of the original Streptomyces rubrum was ACCC41492;

[0031] 3) Liquid fermentation: Put the second mi...

Embodiment 2

[0038] A method for preparing herbicides using starch wastewater, including the following steps:

[0039] 1) Wastewater conditioning: Mix fish scale meal and earthworm feces at a weight ratio of 1:5, and let them stand for 24 hours under indoor ventilation to obtain the first mixture. Mix the first mixture with starch wastewater at a weight ratio of 1:10 Place it in a stirring tank, and stir for 30 minutes at a stirring rate of 10r / min every 3.5h under indoor ventilation conditions, and adjust the pH to 7.4 after treatment for 48 hours to obtain the second mixture;

[0040] 2) Seed preparation: Sterilize and cool the second mixture and inoculate the original Streptomyces erythraea. The inoculation concentration of the original Streptomyces erythropolis is 10 per ml of the sterilized second mixture. 7 Spores were cultured in a shake flask at 28-30°C at 150r / min for 36 hours to obtain liquid seeds. The strain number of the original Streptomyces rubrum was ACCC41492;

[0041] 3) Liquid ...

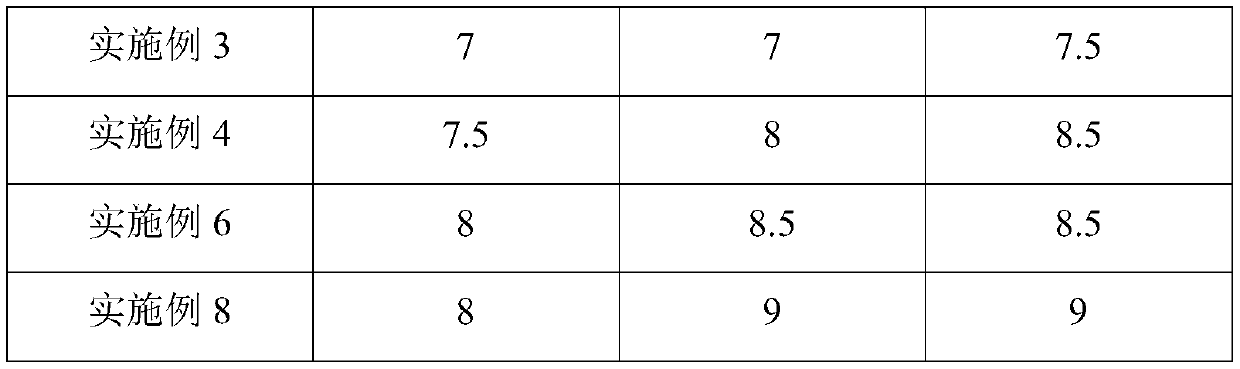

Embodiment 3

[0048] A method for preparing herbicides using starch wastewater, including the following steps:

[0049] 1) Wastewater conditioning: Mix fish scale meal and earthworm feces at a weight ratio of 1:5, and let them stand for 24 hours under indoor ventilation to obtain the first mixture. Mix the first mixture with starch wastewater at a weight ratio of 1:9 Place it in a stirring tank, and stir for 30 minutes at a stirring rate of 10r / min every 3.5h under indoor ventilation conditions, and adjust the pH to 7.2 after treatment for 48h to obtain the second mixture;

[0050] 2) Seed preparation: Sterilize and cool the second mixture and inoculate the original Streptomyces erythraea. The inoculation concentration of the original Streptomyces erythropolis is 5×10 per ml of the sterilized second mixture 6 Spores were cultured in a shake flask at 28-30°C at 150r / min for 36 hours to obtain liquid seeds. The strain number of the original Streptomyces rubrum was ACCC41492;

[0051] 3) Liquid ferme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com