Paste homogenizing and stirring process for lithium ion battery negative electrode

A lithium-ion battery and anode slurry technology, which is applied in battery electrodes, electrode manufacturing, secondary batteries, etc., can solve the problems of low battery cycle life and high cost of negative electrodes, improve equipment utilization, improve cycle life, and shorten completion. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

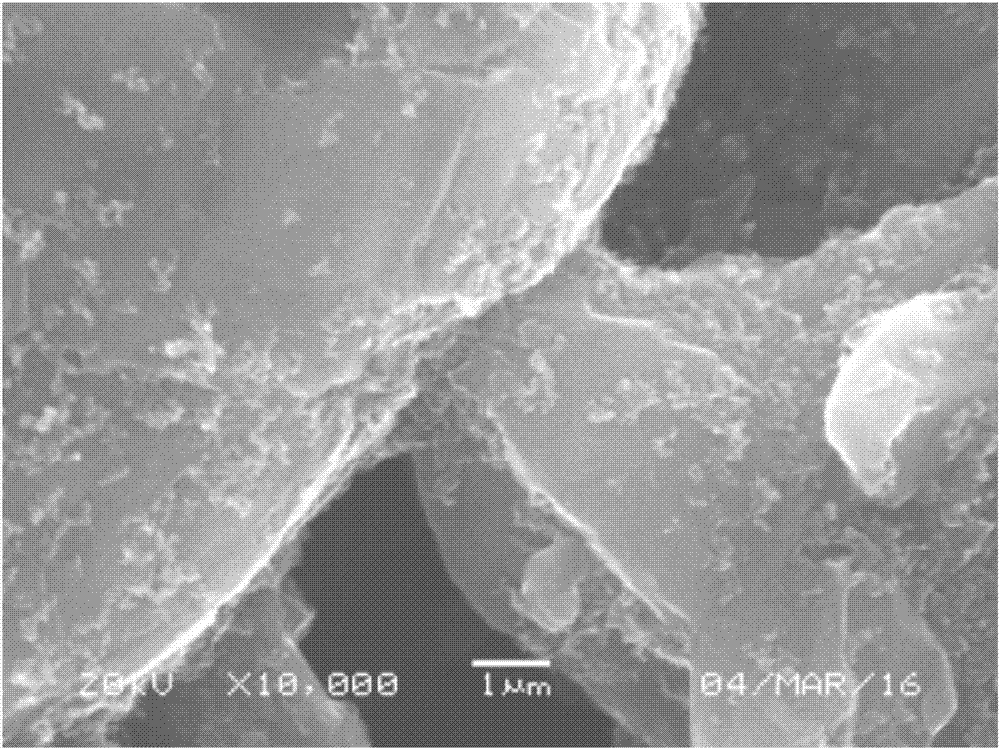

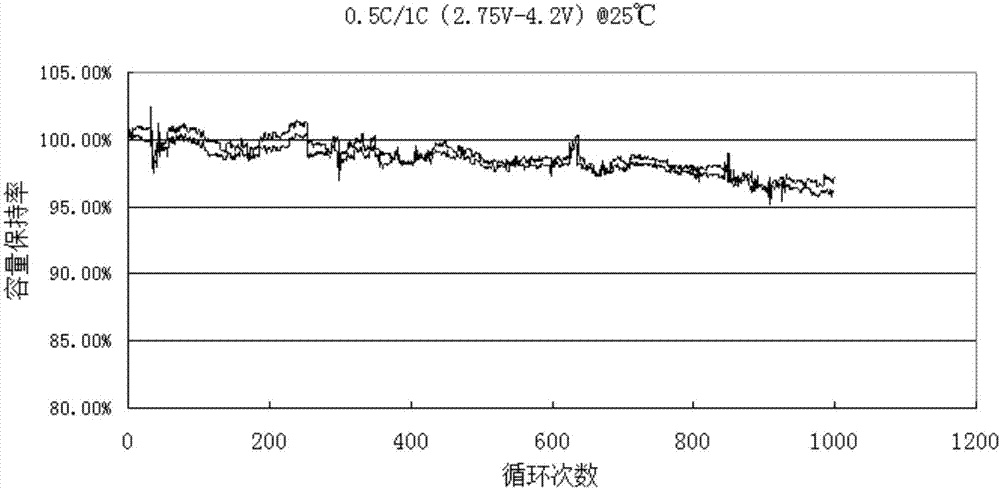

Image

Examples

Embodiment 1

[0043] A preparation method of lithium ion battery negative electrode slurry, comprising the following steps:

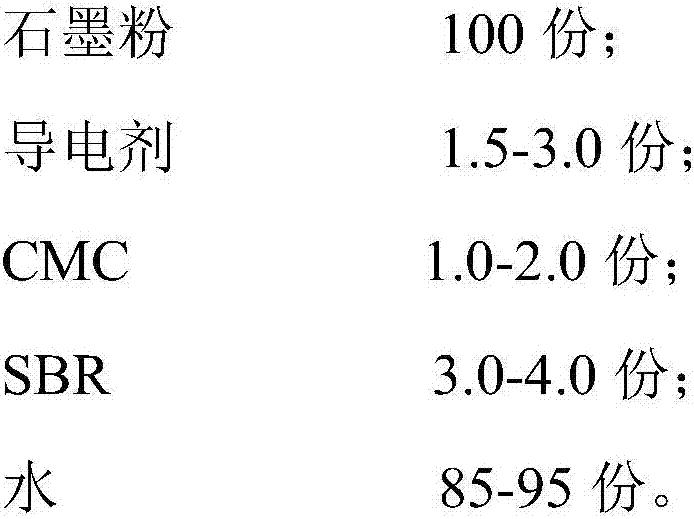

[0044] Weigh the raw material components of the lithium ion battery negative electrode, the raw material components include graphite powder, conductive agent, CMC, SBR and water, and the mass ratio of graphite powder, conductive agent, CMC, SBR and water is 100:2.5 :1:3:85;

[0045] Put the graphite powder and the conductive agent into a dry mixing tank, stir for 15 minutes at a revolution speed of 5 rpm and a rotation speed of 100 rpm to prepare a powder; after mixing the CMC and the water, first Stir 90min under the rotating speed of 864rpm, then stir 30min under the condition of 864rpm, prepare CMC glue;

[0046] Put the powder in a mixer, add the CMC glue with a mass percentage of 8% to the powder, stir for 10 min at a revolution speed of 10 rpm and a rotation speed of 800 rpm, and mix the powder The material is wetted to obtain the first mixed material;

[00...

Embodiment 2

[0052] A preparation method of lithium ion battery negative electrode slurry, comprising the following steps:

[0053] Weigh the raw material components of the lithium ion battery negative electrode, the raw material components include graphite powder, conductive agent, CMC, SBR and water, and the mass ratio of graphite powder, conductive agent, CMC, SBR and water is 100:2.5 :1.5:3.5:90;

[0054] Put the graphite powder and the conductive agent into a dry mixing tank, stir for 13 minutes at a revolution speed of 5 rpm and a rotation speed of 103 rpm to prepare powder; after mixing the CMC and the water, first Stir 95min under the rotating speed of 850rpm, then stir 30min under the condition of 850rpm, prepare CMC glue;

[0055] The powder is placed in a mixer, the CMC glue with a mass percentage of 9% is added to the powder, stirred for 10 min at a revolution speed of 9.5 rpm and a rotation speed of 805 rpm, and the Wetting the powder to obtain the first mixture;

[0056] A...

Embodiment 3

[0061] A preparation method of lithium ion battery negative electrode slurry, comprising the following steps:

[0062] Weigh the raw material components of the lithium ion battery negative electrode, the raw material components include graphite powder, conductive agent, CMC, SBR and water, and the mass ratio of graphite powder, conductive agent, CMC, SBR and water is 100:2 :1:3.2:90;

[0063] Put the graphite powder and the conductive agent into a dry mixing tank, stir for 14min at a revolution speed of 5rpm and a rotation speed of 102rpm to prepare powder; after mixing the CMC and the water, first Stir for 88min under the rotating speed of 88min, then stir 28min under the condition of 880rpm, prepare CMC glue;

[0064] The powder is placed in a mixer, the CMC glue with a mass percentage of 10% is added to the powder, stirred for 11 min at a revolution speed of 10.5 rpm and a rotation speed of 798 rpm, and the Wetting the powder to obtain the first mixture;

[0065] Add the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com