Anti-twisting winding core barrel for winding of water pipe connector PTFE thread seal tape and anti-twisting mechanism of anti-twisting winding core barrel

A technology of water pipe joints and raw material belts, which is applied in the direction of thin material handling, sending objects, transportation and packaging, etc., can solve the problems of inconvenience and waste in construction, and achieve the effect of convenient construction, avoidance of waste, and avoidance of torsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

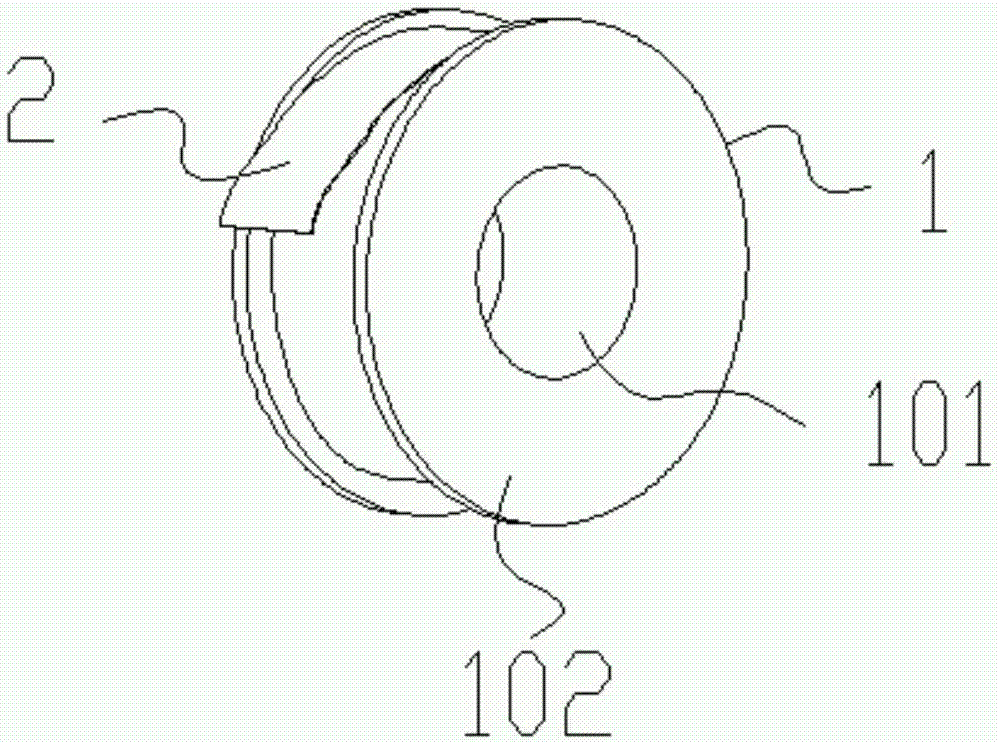

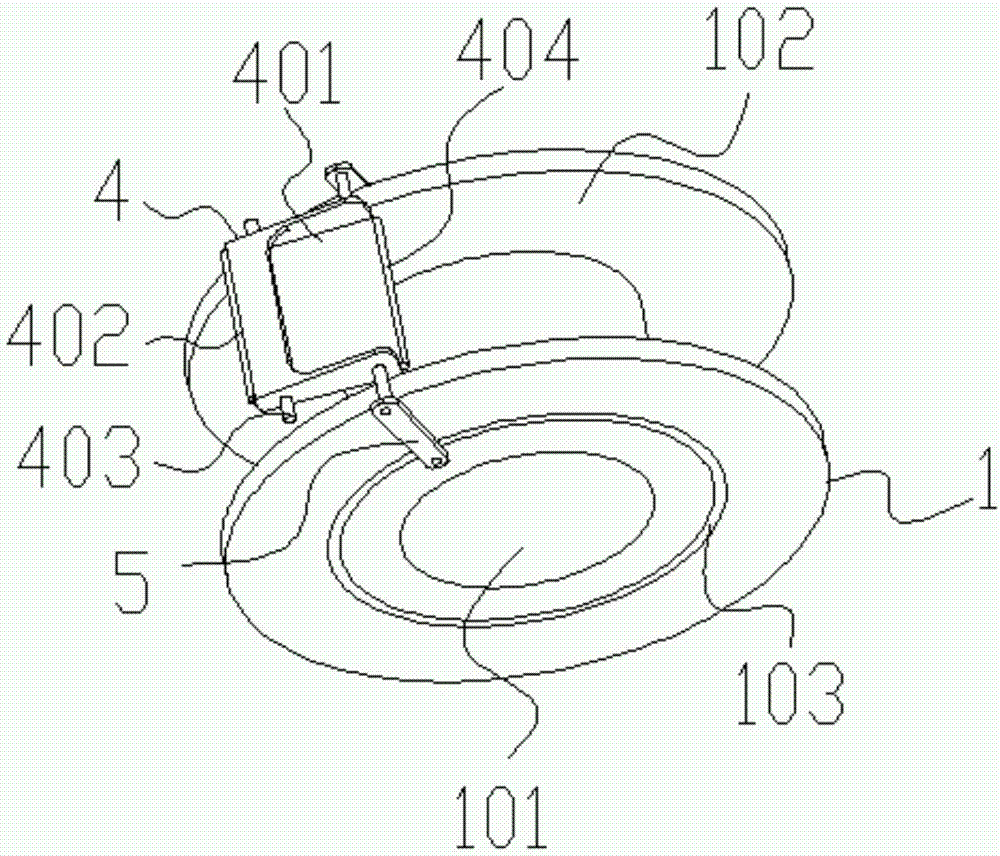

[0028] Such as Figure 3-Figure 6 As shown, the present invention is an anti-twist mandrel for water pipe joint raw tape winding. Its specific structure is as follows: it includes a mandrel 1 with a central hole 101 in the center and side walls 102 on both sides; Between the two side walls 102, there is a hollow flattening head 4 that rotates around the center of the mandrel 1, and the flattening head 4 is fixed by a movably connected rotating arm 5; Enter at the end and send out from the front. With this design, a flattening head is installed before the raw material tape core barrel is discharged, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com