A recyclable floating composite photocatalytic ball and its preparation method and application

A technology of composite photocatalysis and composite light, which is applied in the field of photocatalytic oxidation and degradation of pollutants, can solve the problems of effective degradation and floating of difficult pollutants, and achieve the effect of high degradation efficiency, low cost and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] (1) Preparation of visible light-responsive nano-photocatalytic active components

[0064] Take 1.0gTiO 2 (P25), 200mL absolute ethanol and 1.5mL NaOH aqueous solution (concentration: 5g / L) were placed in a flask, stirred and adsorbed in a water bath at 30°C. After adsorption equilibrium (more than 12 hours), TiO 2 (P25) The surface forms a stable OH-rich - the adsorbed water layer.

[0065] Take another 50 mL of absolute ethanol dissolved with 0.02 g of silver nitrate, and drop it into the adsorption equilibrium system drop by drop using a constant pressure funnel. Silver nitrate will diffuse into the adsorbed water layer, and OH - The ions undergo a precipitation decomposition reaction, and the TiO 2 (P25) Ag nanoparticles formed in the surface adsorption layer. After the reaction was completed (5 hours), the temperature of the water bath was raised to 80°C, and the 2 The suspension system of (P25)-Ag composite particles was aged and heat-treated for 1 hour. A...

Embodiment 2

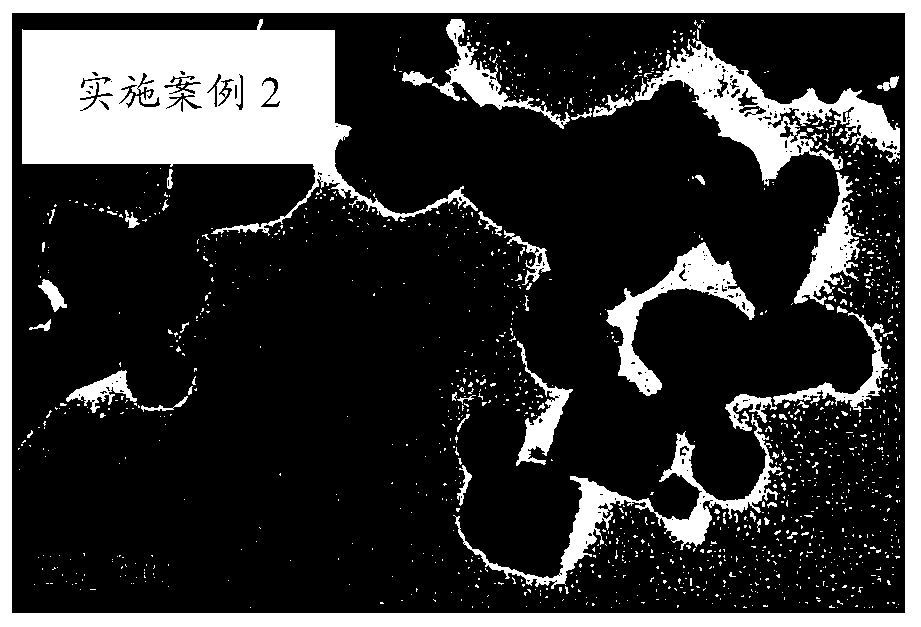

[0085] (1) Catalyst preparation

[0086] Take 1.0g TiO 2 (P25), 200mL absolute ethanol and 1.5mL NaOH aqueous solution (concentration: 10g / L) were placed in a flask, stirred and adsorbed in a 30°C water bath. After adsorption equilibrium (more than 12 hours), TiO 2 (P25) The surface forms a stable OH-rich - the adsorbed water layer.

[0087] Take another 50 mL of absolute ethanol dissolved with 0.04 g of silver nitrate, and drop it into the adsorption equilibrium system drop by drop using a constant pressure funnel. Silver nitrate will diffuse into the adsorbed water layer, and OH - The ions undergo a precipitation decomposition reaction, and the TiO 2 (P25) Ag nanoparticles formed in the surface adsorption layer. After the reaction was completed (5 hours), the temperature of the water bath was raised to 80°C, and the 2 The suspension system of (P25)-Ag composite particles was aged and heat-treated for 1 hour. After the reaction system is cooled to room temperature aft...

Embodiment 3

[0107] (1) Catalyst preparation

[0108] Take 1.0g TiO 2 (P25), 200mL absolute ethanol and 1.5mL NaOH aqueous solution (concentration: 15g / L) were placed in a flask, stirred and adsorbed in a 30°C water bath. After adsorption equilibrium (more than 12 hours), TiO 2 (P25) The surface forms a stable OH-rich - the adsorbed water layer.

[0109] Take another 50 mL of absolute ethanol dissolved with 0.06 g of silver nitrate, and drop it into the adsorption equilibrium system drop by drop using a constant pressure funnel. Silver nitrate will diffuse into the adsorbed water layer, and OH - The ions undergo a precipitation decomposition reaction, and the TiO 2 (P25) Ag nanoparticles formed in the surface adsorption layer. After the reaction was completed (5 hours), the temperature of the water bath was raised to 80°C, and the 2 The suspension system of (P25)-Ag composite particles was aged and heat-treated for 1 hour. After the reaction system is cooled to room temperature aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com