Heavy metal ion adsorbent and application thereof

A technology of heavy metal ions and adsorbents, applied in the fields of application, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problems of bringing in non-tobacco components, etc., and achieve easy acquisition, short treatment cycle, and high removal rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

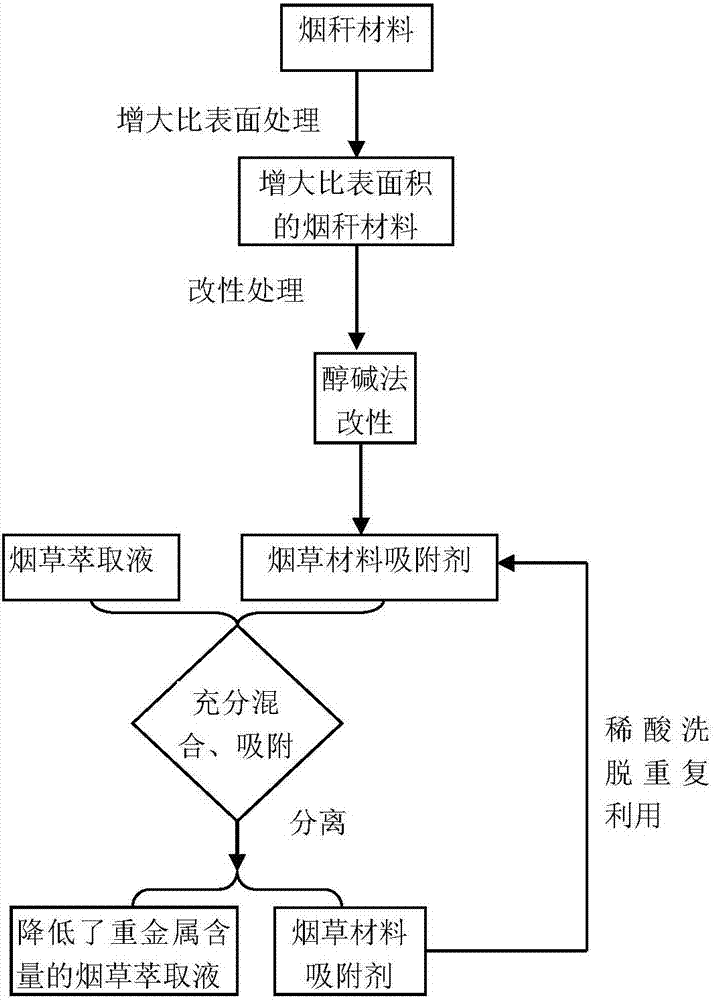

[0026] The heavy metal ion adsorbent of this embodiment, the preparation flow chart is as follows figure 1 As shown, the following method is used to prepare:

[0027] 1) Grind the dried tobacco stalks to obtain tobacco stalk powder with a particle size of 0.15mm~0.25mm (denoted as A powder);

[0028] 2) Weigh 5.0g of A powder, and add 100mL ethanol and NaOH solution to the alcohol-alkali modification solution (the concentration of NaOH solution is 0.4mol / L, the volume ratio of ethanol to NaOH solution is 1:1), shaker After 22 hours of shaking treatment (circular oscillation, rotation speed of 150r / min), filter with a 150-mesh nylon screen, then wash with deionized water 3 times, and dry at 55°C to obtain an alcohol-alkali modified adsorbent A.

[0029] When the heavy metal ion adsorbent of this embodiment is used to adsorb heavy metal ions in the tobacco extract, weigh 0.2g of the alcohol-alkali modified adsorbent A, add 15 mL of the tobacco extract, and oscillate and adsorb for 2.0...

Embodiment 2

[0032] The heavy metal ion adsorbent of this embodiment is prepared by the following method:

[0033] 1) Grind the dried tobacco stalks to obtain tobacco stalk powder with a particle size of 0.25mm~0.42mm (denoted as B powder);

[0034] 2) Weigh 5.0g of B powder, add 100mL methanol and KOH solution to the alcohol-alkali modification solution (the concentration of KOH solution is 0.2mol / L, the volume ratio of methanol to KOH solution is 1:2), shake on a shaker After 36h (circular oscillation, rotating speed 120r / min), filter with 150-mesh nylon screen, then wash with deionized water 3 times, and dry at 55°C to obtain the alcohol-alkali modified adsorbent.

[0035] When the heavy metal ion adsorbent of this embodiment is used to adsorb heavy metal ions in the tobacco extract, weigh 0.2g of the alcohol-alkali modified adsorbent, add 15 mL of the tobacco extract, and oscillate and adsorb for 2.5h at a rotation speed of 120r / min. Filtration separates the heavy metal ion adsorbent from th...

Embodiment 3

[0038] The heavy metal ion adsorbent of this embodiment is prepared by the following method:

[0039] 1) Grind the dried tobacco stalks to obtain tobacco stalk powder with a particle size of 0.42mm~0.84mm (denoted as C powder);

[0040] 2) Weigh 5.0g of C powder, add 100mL of mixed solvent composed of ethanol and NaOH solution (the concentration of NaOH solution is 0.6mol / L, the volume ratio of ethanol and NaOH solution is 2:1), shake on a shaker for 40h ( Circumferentially oscillate at a rotation speed of 180r / min), filter with a 150-mesh nylon screen, then wash with deionized water 3 times, and dry at 55°C to obtain an alcohol-alkali modified adsorbent.

[0041] When the adsorbent of this embodiment is used to adsorb heavy metal ions in the tobacco extract, weigh 0.2g of the alcohol-alkali modified adsorbent, add 15 mL of the tobacco extract, and oscillate and adsorb for 3.0h at a rotation speed of 200r / min. The heavy metal ion adsorbent is separated from the tobacco extract.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com