Anti-corrosion insulating safe liquid heating tube

A technology for insulating and safe heating pipes, which is applied to corrosion-resistant insulating safe liquid heating pipes and liquid heating. It can solve the problems of slow response of bimetals, damaged components, and large movement deviation, and achieve uniform and stable heating, high safety, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to illustrate the embodiments of the present application or the technical solutions in the prior art more clearly, the embodiments will be briefly introduced below.

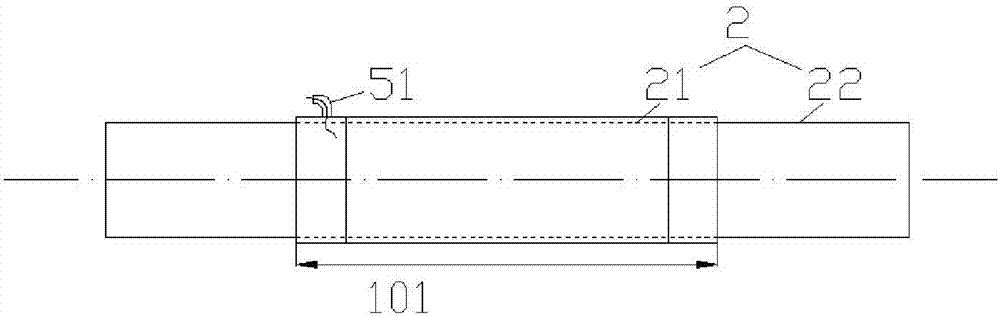

[0019] like Figure 1~3 , a corrosion-resistant insulated safety liquid heating tube 100, in image 3 Frame the heating area 101, which includes a ceramic tube 2, a heating film 3, an insulating layer 4, and a housing 5 from the inside to the outside. Filled with heated liquid 1, the ceramic tube 2 has a main body 21 in the middle and ends 22 on both sides, and the heating film 3 has a thickness of 0.08-0.2mm, and is coated on the main body of the ceramic tube 2 by screen printing The outer surface of part 21, after coating, the thickness deviation of each place is within ±10%. The insulating layer 4 is obtained by spraying a layer of insulating material on the outer surface of the heating film 3. The housing 5 is installed on the end of the ceramic tube 2. part 22, the outer side of one end of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com