Device for testing double-sided solar cell

A solar cell and double-sided technology, which is applied in photovoltaic power generation, electrical components, photovoltaic system monitoring, etc., can solve problems affecting the accuracy of test results, falsely high power test, and enhanced light intensity on one side of the cell, to reduce Effects of interaction, reduced number of uses, accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

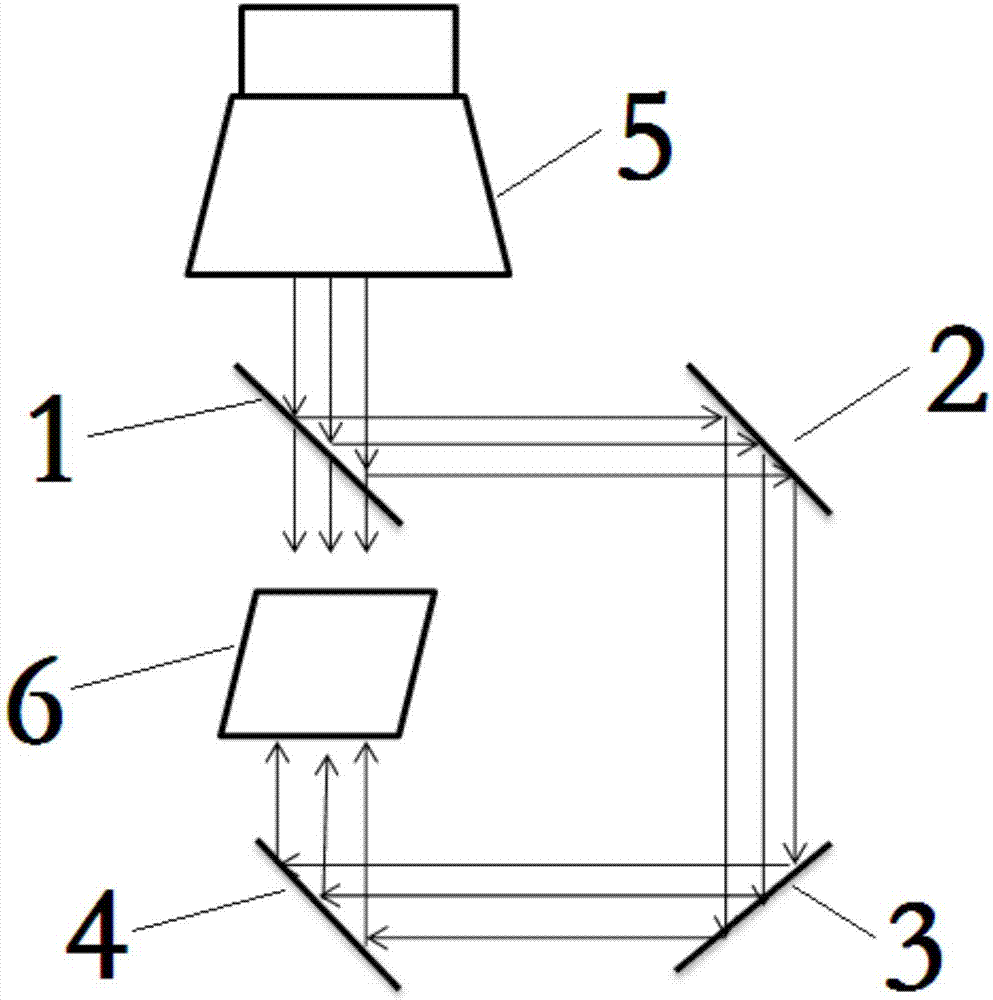

[0033] Example 1: Combining figure 2 , an apparatus for testing bifacial solar cells comprising a xenon lamp 5,

[0034] The device also includes a first beam splitter 1 arranged directly under the xenon lamp 5, and the mirror surface of the first beam splitter 1 is set at 45° relative to the incident light of the xenon lamp 5;

[0035] The device also includes a second mirror 2 whose mirror surface and horizontal position are parallel to the first beam splitter 1, and the oblique upper part of the first beam splitter 1 corresponds to the reflection surface of the second mirror 2;

[0036] The device also includes a third reflector 3 positioned perpendicular to the second reflector 2, the third reflector 3 is arranged directly below the second reflector 2, and the reflection surface of the third reflector 3 is 45° upward and its level Orientation is opposite to the horizontal orientation of the reflection surface of the second reflector 2;

[0037] The device also includes ...

Embodiment 2

[0040] Embodiment 2: As for the device described in Embodiment 1, the first beam splitter 1 can be selected according to the light intensity requirements on the front and back of the battery sheet 6, such as requiring both the front and back sides to use 1000W / m 2 The first beam splitter 1 can use an optical splitter with a splitting ratio of 50%: the transmittance and reflectance are respectively 50%, so that half of the light source is transmitted and half is reflected. The device can be used to test the conversion efficiency of the front and back sides of the battery sheet 6, and can also be used to test the power of the front and back sides of the module.

Embodiment 3

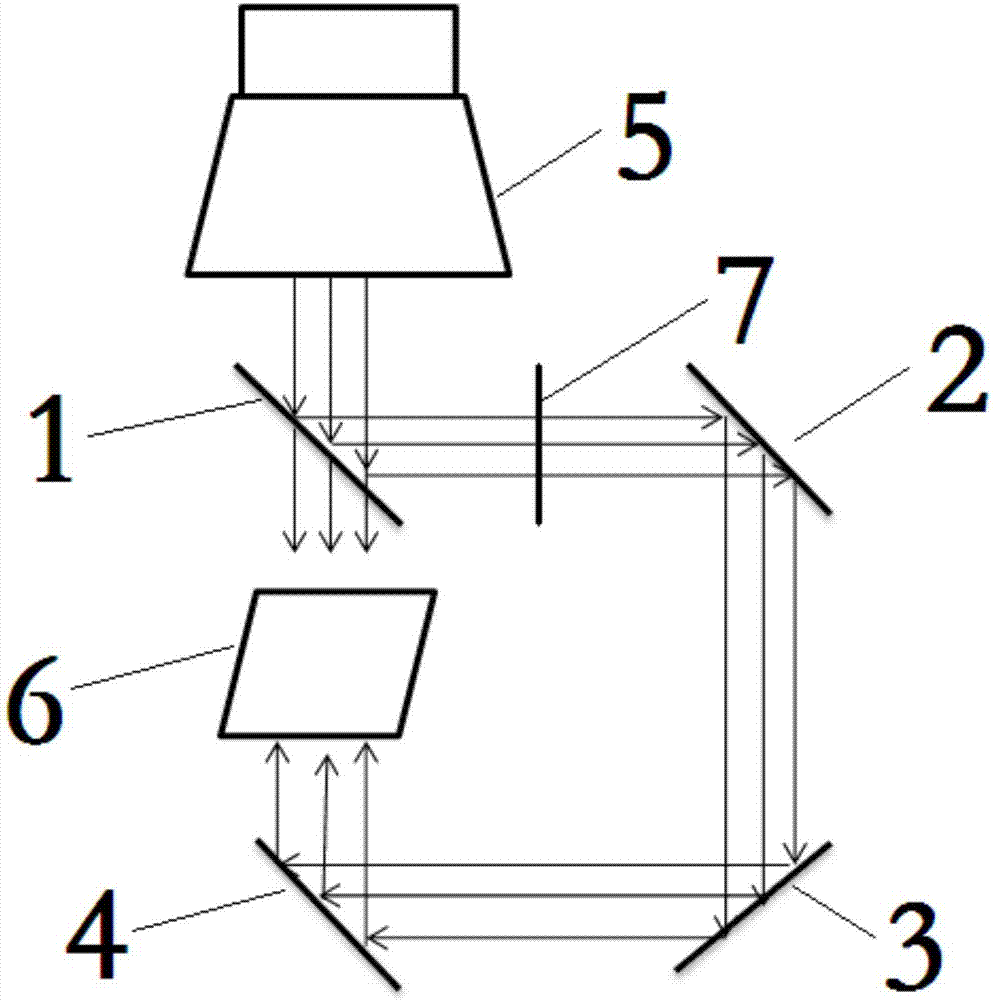

[0041] Example 3: Binding image 3 , as the device described in Embodiment 1, in order to realize the different requirements of the light intensity on the back of the battery sheet 6, a vertical light-transmitting plate 7 is added between the first beam splitter 1 and the second reflector 2, and the light-transmitting range is 50-95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com