Automatic control system for ore storage bin

An automatic control system and mining silo technology, applied in the general control system, control/adjustment system, program control, etc., can solve the problems of large impact and rollover of vehicles, achieve uniform loading and distribution of feeding materials, and avoid vehicles dumping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

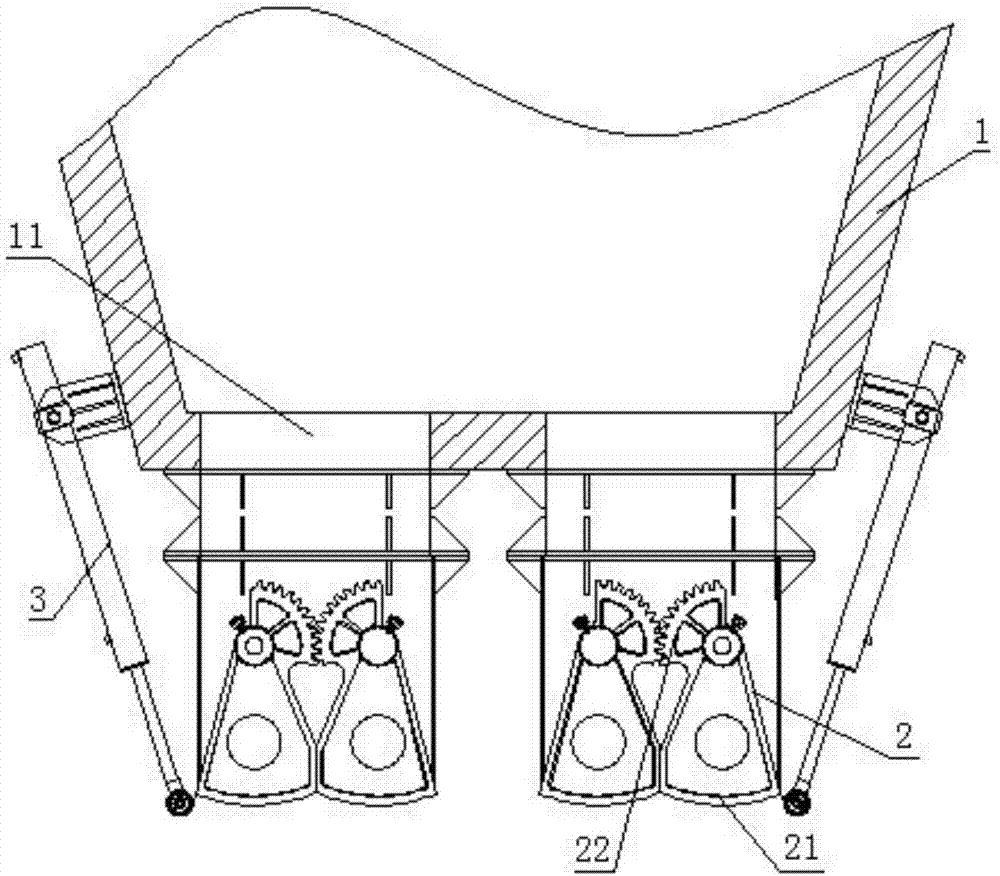

[0026] Mine bin automatic control system, including industrial computer, industrial control electromechanical connection with PLC controller, PLC controller is electrically connected with interleaved control module, interleaved control module is electrically connected with several electromagnetic reversing valves, and electromagnetic reversing valve is connected with The hydraulic cylinder 3 opened and closed by the opening and closing mechanism 2 on the discharge port 11 of 1.

[0027] The opening and closing mechanism 2 is a jaw-type ore-drawing valve. The jaw-type ore-drawing valve 2 includes two sets of rotating valve plates 21. Both sets of rotating valve plates 21 are hinged with the mine bin 1. Gears 22 are connected to the rotating valve plates 21. Two sets of rotating valve plates The gear 22 on the rotating valve plate 21 meshes, and one end of one group of rotating valve plates 21 away from the gear 22 is hinged to the piston rod of the hydraulic cylinder 3 . The tw...

Embodiment 2

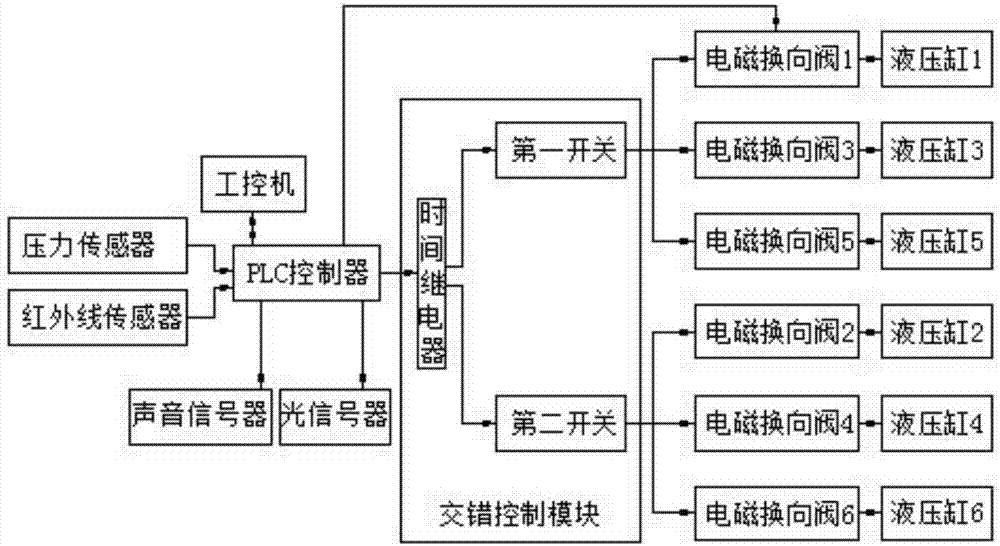

[0031] On the basis of Embodiment 1, the interleaved control module includes a time relay, the time relay is electrically connected to the PLC controller, the normally open contact of the time relay is electrically connected to the first switch, and the first switch is electromagnetically commutated with a part thereof The positive stroke contact of the valve is electrically connected; the normally closed contact of the time relay is electrically connected to a second switch, and the second switch is electrically connected to the positive stroke contact of another part of the electromagnetic reversing valve. The closing time and disconnection of the time relay The time is the same; the reverse travel contact of the electromagnetic reversing valve is electrically connected with the PLC controller.

[0032]When the vehicle is in place, the PLC controller is connected to the contact of the time relay. The closing time and opening time of the time relay are the same, so the first ...

Embodiment 3

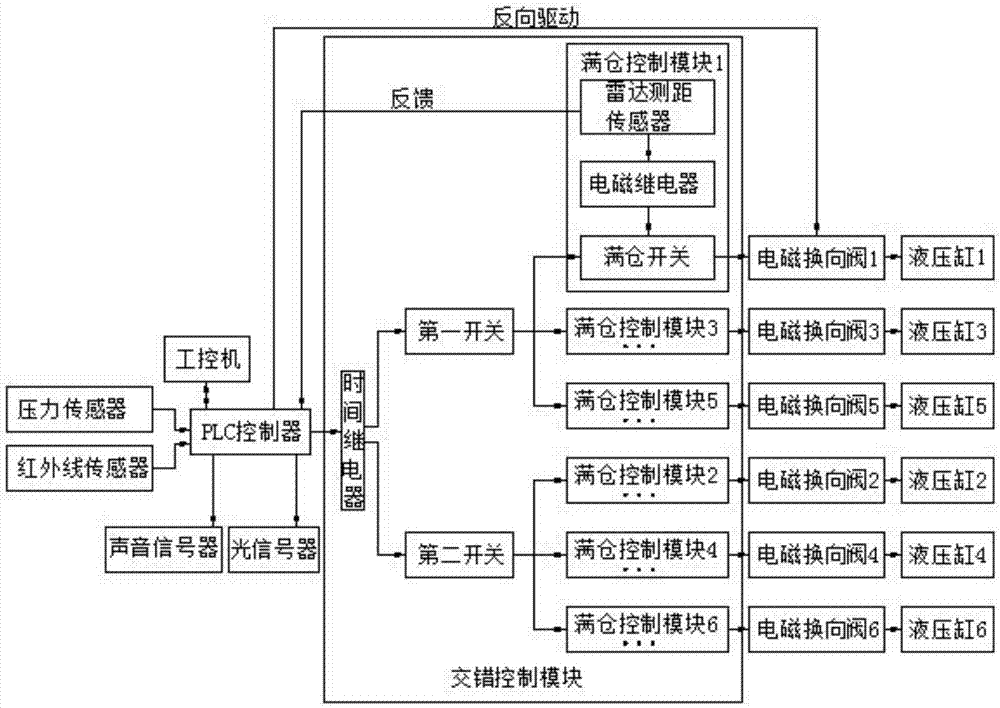

[0034] On the basis of Embodiment 1 or Embodiment 2, the interleaved control module includes a time relay, the time relay is electrically connected to the PLC controller, the normally open contact of the time relay is electrically connected to the first switch, and the normally closed contact of the time relay The contacts are electrically connected to a second switch; the positive stroke contacts of several electromagnetic reversing valves are connected to a full warehouse control module, the output end of the first switch is electrically connected to a part of the full warehouse control module, and the second switch is connected to the other part of the full warehouse control module. The control module is electrically connected; the full warehouse control module is electrically connected to the PLC controller to form a feedback circuit, the reverse travel contact of the electromagnetic reversing valve is electrically connected to the PLC controller, and the closing time of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com