Method for obtaining reoxidized analysis sample in steam service environment

A technology of service environment and acquisition method, which is applied in the field of obtaining samples for reoxidation analysis under steam service environment, can solve the problems of difficult realization and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

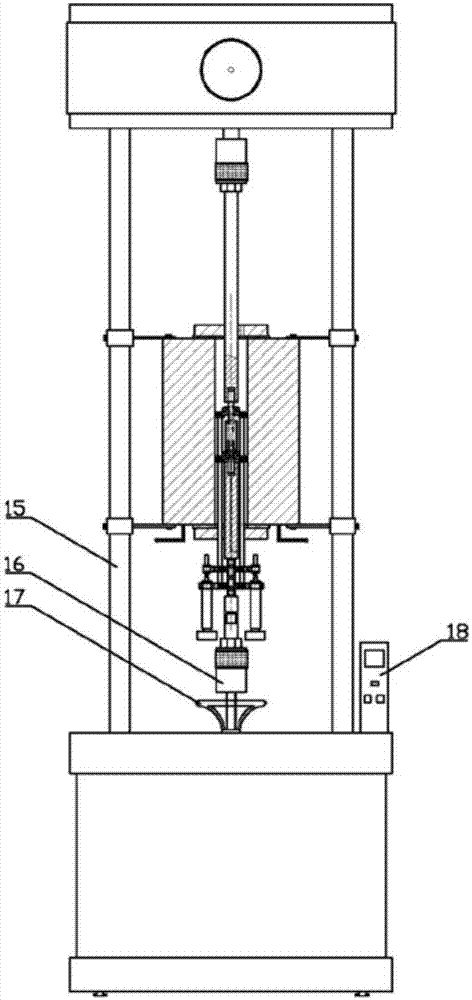

[0027] Research question: After the material super304H is exposed to 600°C, 20MPa steam environment, the creep stress level is 105MPa, and the creep damage degree is 50% (corresponding to about 50,000 hours of operation time), the peeling of the primary scale surface layer is related to steam reoxidation oxidation mechanism.

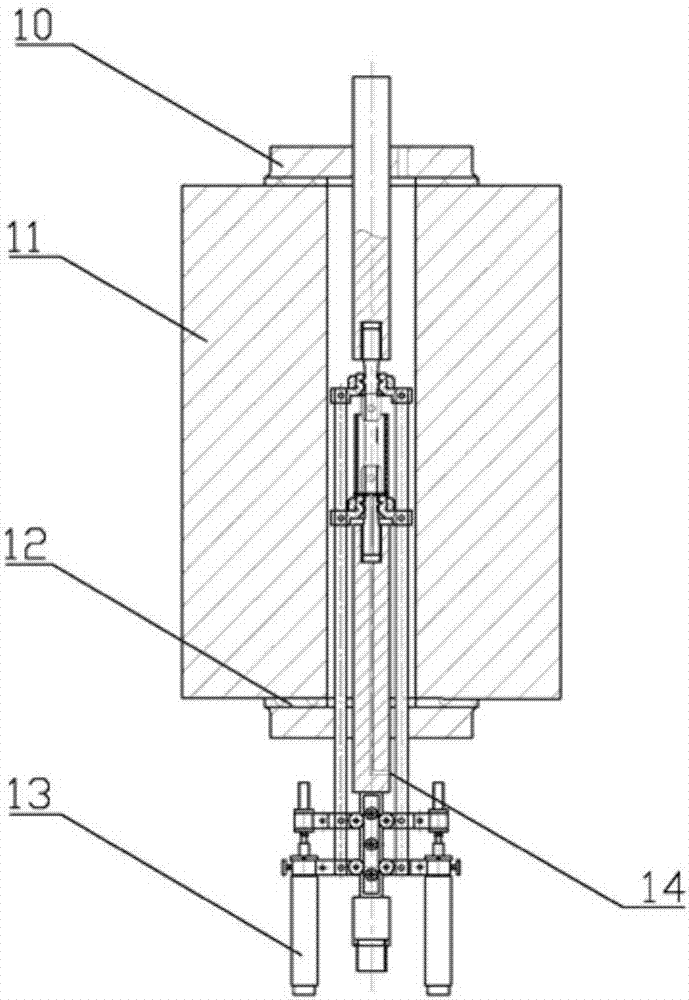

[0028] According to the requirements of the creep machine, make sample 4 and a comparison sample of the same size and shape, such as Figure 5 shown.

[0029] The methods for obtaining reoxidation analysis samples under steam service environment are as follows:

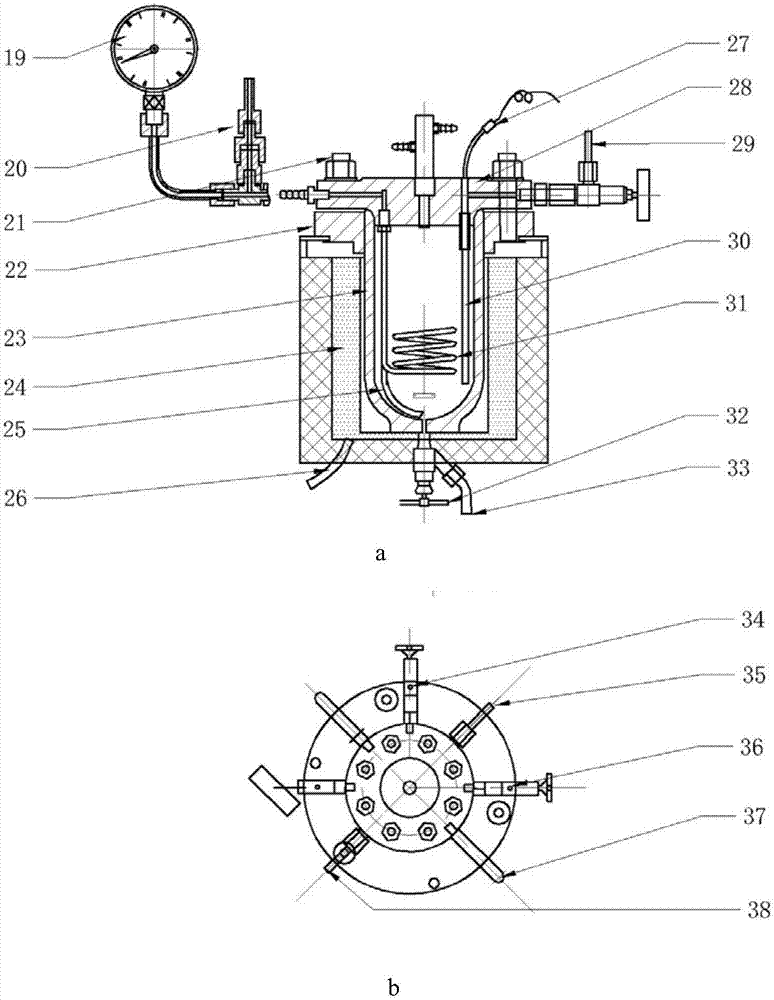

[0030] 1) High temperature and high pressure reactor such as figure 1 a- figure 1 As shown in b, firstly, in the high-temperature and high-pressure reactor, use oxygen and high-temperature H 2 O steam for steam oxidation of sample 4. Oxygen simulated oxidation is a widely used method for simulating steam oxidation by accelerating oxidation. The amount of oxygen added is determined accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com