Four-planetary-line automatic transmission and vehicle

A technology of automatic transmission and planetary row, which is applied in the direction of vehicle parts, vehicle gearboxes, transmission components, etc., can solve the problems of difficult lightweight design of the box, complex structure, and unfavorable lightweight design, so as to reduce the difficulty of processing and manufacturing, Improved transmission efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

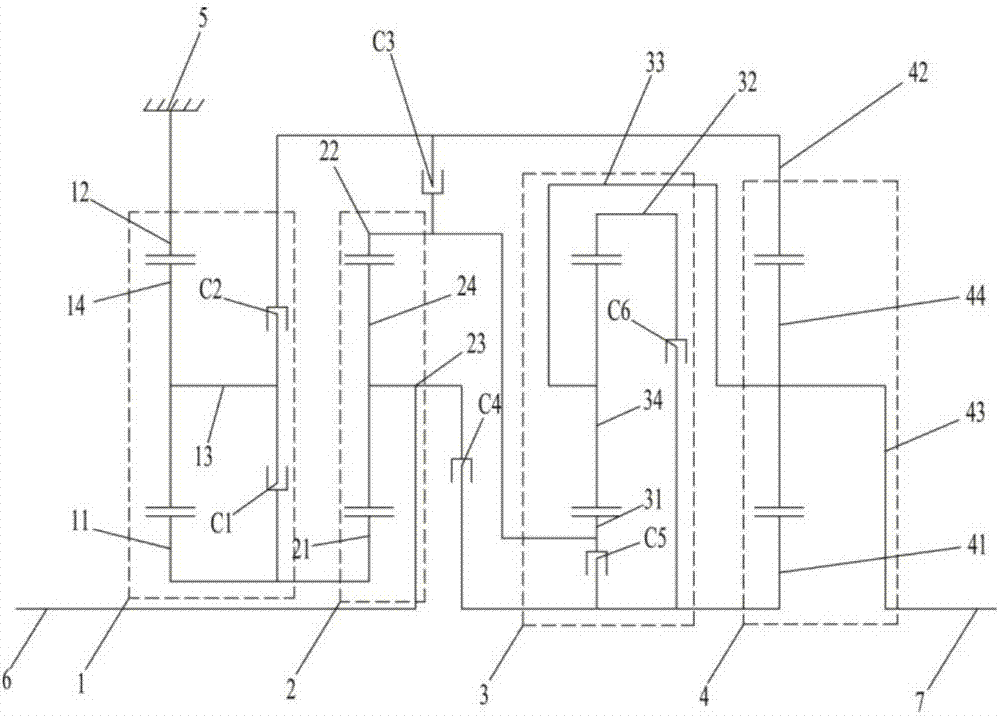

[0037] like figure 1 As shown, a four-planetary automatic transmission according to an embodiment of the present invention is schematically shown, which includes an input member 6 and an output member 7, and the first planetary row 1, the second planetary row 2, the The third planetary row 3 and the fourth planetary row 4, each planetary row has a sun gear, a ring gear, a planetary carrier and a planetary gear set that cooperate with each other, and the first clutch C1, the second clutch C2, and the third clutch C3 , the fourth clutch C4, the fifth clutch C5 and the sixth clutch C6; in the same planetary row, the sun gear and the planetary gear set are externally meshed, the planetary gear set is internally meshed with the ring gear, and the planetary gear set is installed on the corresponding planetary gear through the bearing The above-mentioned six clutches can be used as multi-plate wet clutches or dog-tooth clutches. For the convenience of expression, the sun gear, ring g...

Embodiment 2

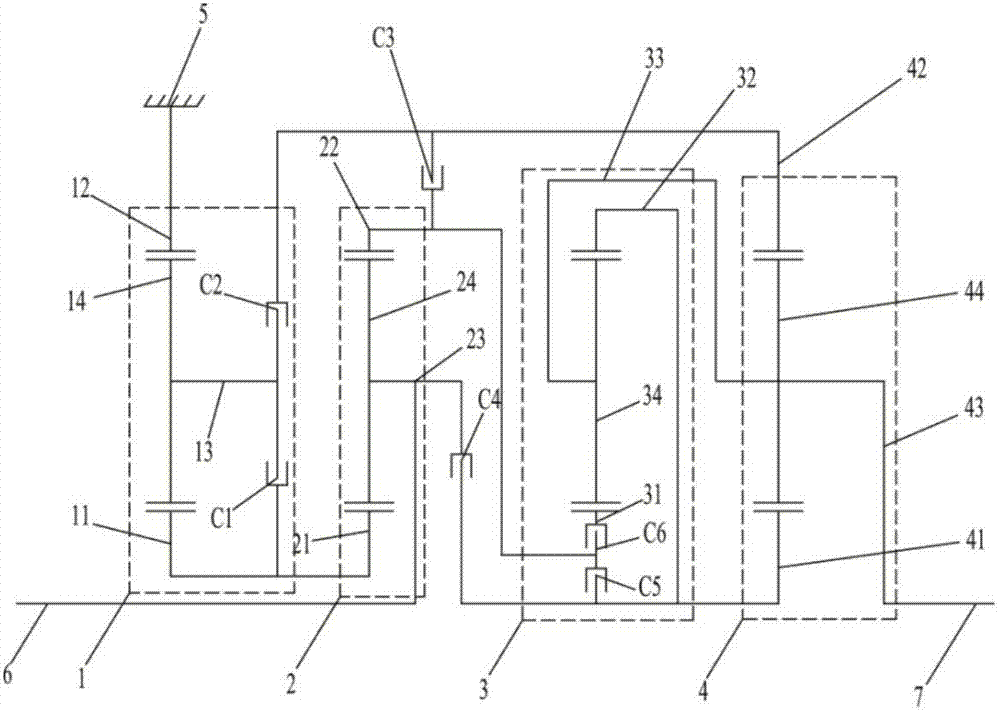

[0059] like figure 2 As shown, the four-planetary automatic transmission in this embodiment is substantially the same as that in Embodiment 1, except that the position of the sixth clutch C6 is different. In this embodiment, the sixth clutch C6 is engaged between the second ring gear 22 and the third sun gear. Between the wheels 31, that is, the second ring gear 22 is connected to the third sun gear 31 through the sixth clutch C6, and the third ring gear 32 is fixedly connected to the fourth sun gear 41; although in this embodiment, the sixth clutch C6 The setting position of is different from that of Embodiment 1, but the four-planetary automatic transmission of this embodiment shares a speed ratio conversion logic table (Table 1) with Embodiment 1, and the power under each gear of the two The transmission route diagrams are also basically the same, that is, the functions realized by the four-planetary automatic transmission in this embodiment are consistent with those reali...

Embodiment 3

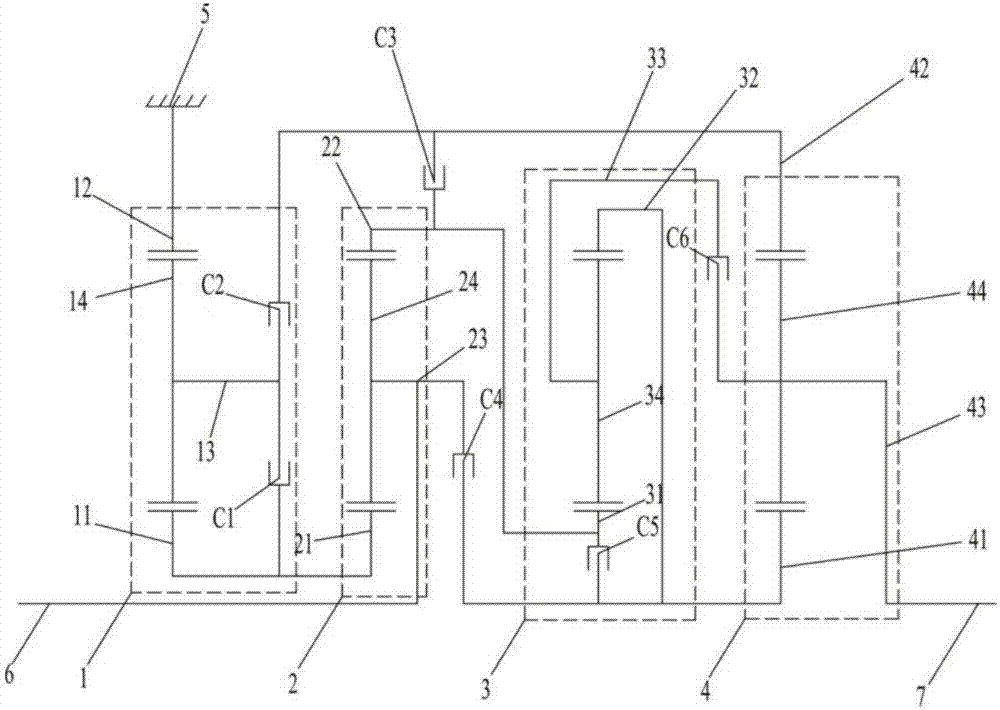

[0061] like image 3 As shown, the four-planetary automatic transmission in this embodiment is substantially the same as that in Embodiment 1, except that the position of the sixth clutch C6 is different. The sixth clutch C6 in this embodiment is engaged between the third planetary carrier 33 and the fourth Between the planetary carriers 43, that is, the third planetary carrier 33 is connected to the fourth planetary carrier 43 through the sixth clutch C6, while the third ring gear 32 is fixedly connected to the fourth sun gear 41, so that when the third clutch C3 is closed , realize the overall rotation of the third planetary row 3; although in this embodiment, the setting position of the sixth clutch C6 is different from the setting position of the embodiment 1, the four-planetary automatic transmission of the present embodiment is shared with the embodiment 1 A speed ratio conversion logic table (Table 1), and the power transmission route map under each gear of the two is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com