Noise reduction and active return structure of friction plate

A friction plate and noise reduction technology, applied in the direction of noise/vibration control, brake type, brake components, etc., can solve the problems of no active return, increased fuel consumption, large drag torque, etc., to reduce the drag torque , reduce fuel consumption and solve noise problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

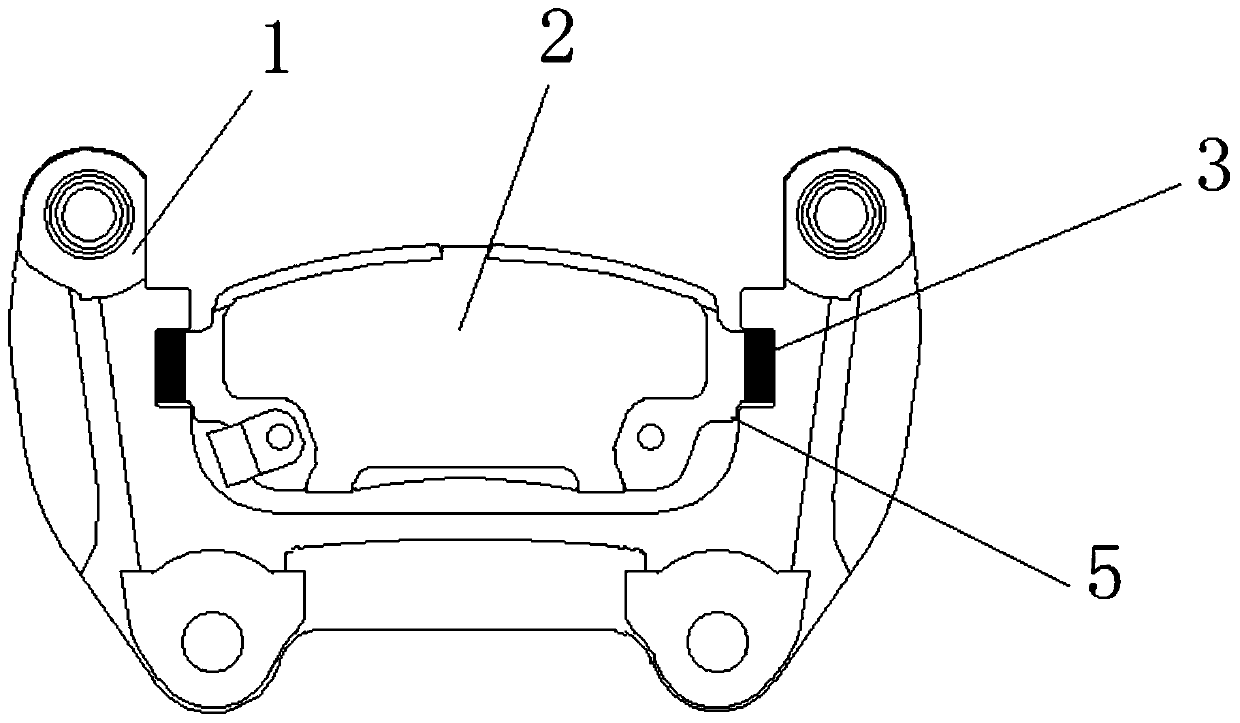

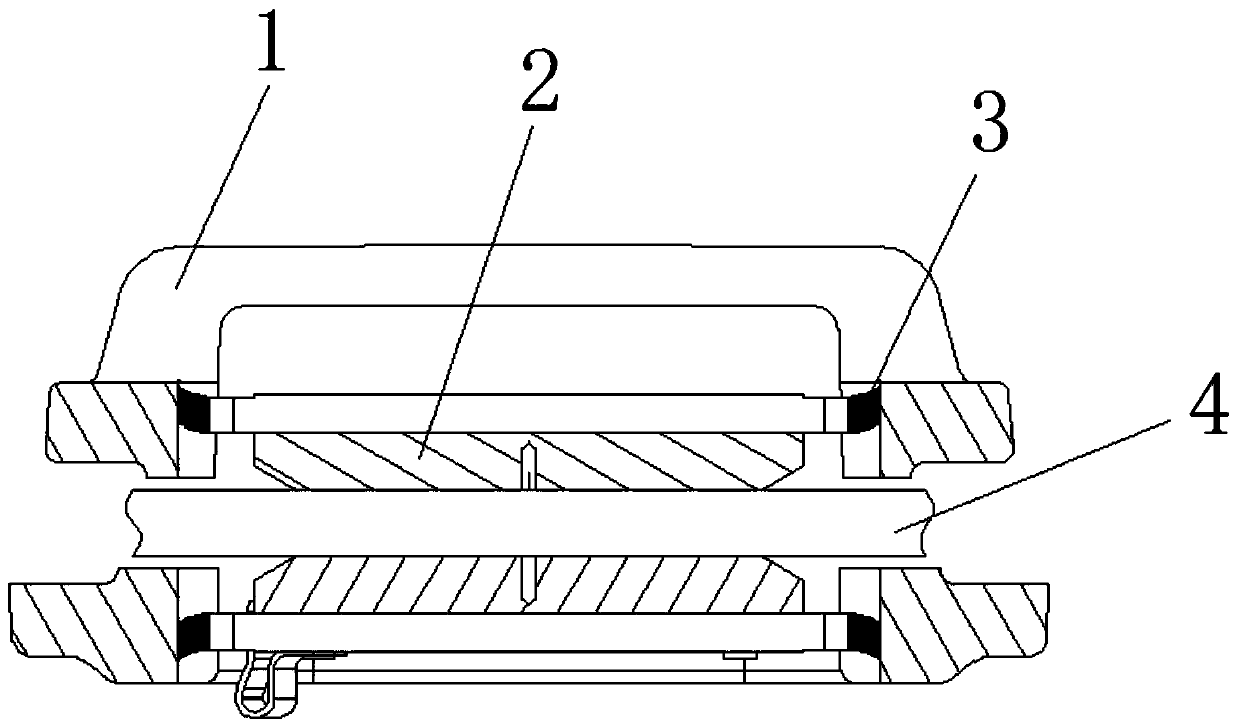

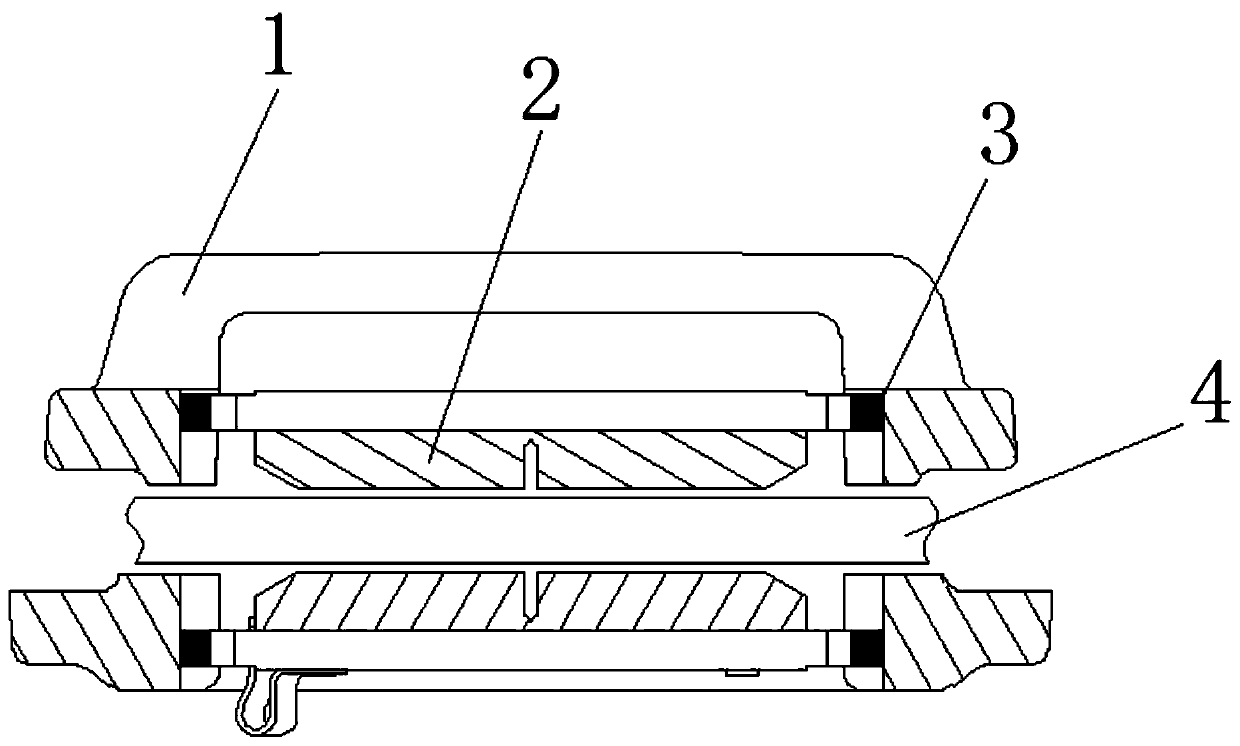

[0012] As shown in the figure, this friction plate noise reduction and active return structure mainly includes bracket 1 and friction plate 2. The bumps at both ends of the back of the friction plate 2 are embedded in the grooves at the corresponding positions of the bracket 1, and rubber is provided on the bumps. Part 3, the bump is in contact with the groove through the rubber part 3, so as to solve the problem of noise generated by the collision between metals during driving. The rubber part 3 and the groove of the bracket 1 are interference fit, and the friction plate 2 is pushed and braked by the piston Disk 4 is in contact. Bosses 5 are provided at the bottom of the bumps at both ends of the back of the friction plate 2, and the bosses 5 at both ends of the back of the friction plate 2 are stressed during braking, thereby solving the problem that the rubber part 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com