Active returning mechanism for friction plate

A return mechanism and friction plate technology, applied in the direction of brake actuators, gear transmission mechanisms, mechanical equipment, etc., can solve the problems of increasing fuel consumption and dragging torque of automobiles, and achieve the goal of reducing fuel consumption and reducing dragging torque Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

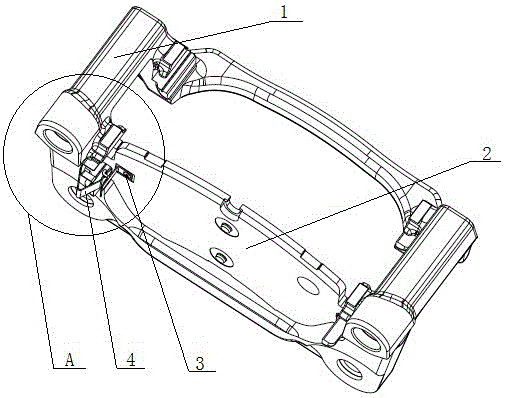

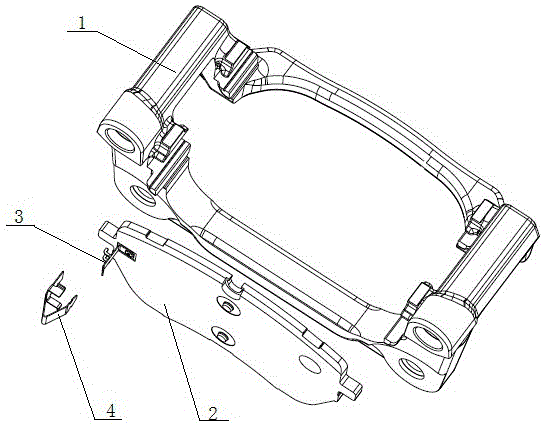

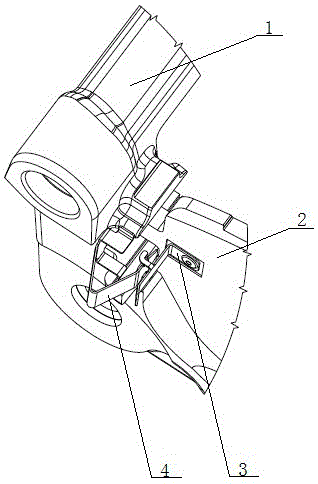

[0018] Such as figure 1 , figure 2 , image 3 As shown, a friction plate active return mechanism includes a bracket 1 and a friction plate 2. The friction plate 2 is fixedly installed in the bracket 1, and one side of the friction plate 2 is riveted with a buckle 3, and the buckle 3 It is L-shaped; a spring 4 is clamped on the bracket 1, and the spring 4 matches the buckle 3; as Figure 4 As shown, one end of the buckle 3 is provided with a fixed installation hole 31, and the other end is bent to form a free end 32 of the buckle. The spring limiter 33 is L-shaped to prevent falling off; as Figure 5 As shown, one end of the spring 4 is provided with a limit groove 41 matching the spring limiter 33, and the other end is fixedly connected with an upper clamp 42 and a lower clamp 43, and one side of the upper clamp 42 is upward. Bending to form the free end 44 of the upper clip, one end of the lower clip 43 is bent downward to form the free end 45 of the lower clip, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com