Lubricant guiding cover and transmission device having the same

A transmission device and lubricant technology, which is applied in transmission device parts, gear lubrication/cooling, mechanical equipment, etc., can solve the problems of improving lubricant delivery without this, and achieve reduced mixing, low lubricant loss, and drag torque little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

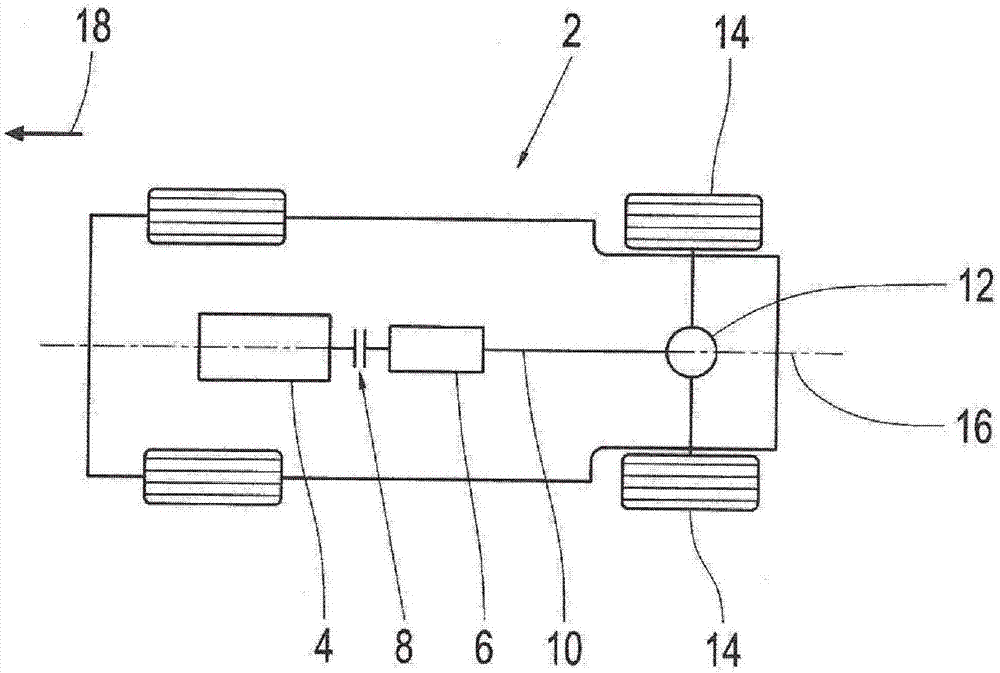

[0022] figure 1 A schematic vehicle diagram of a motor vehicle 2 is shown with a drive motor 4 , a transmission 6 and a clutch 8 arranged between the drive motor 4 and the transmission 6 . The transmission 6 is connected to the two rear wheels 14 via a drive shaft 10 and a differential 12 . A central axis 16 extends through the transmission 6 , the central axis 16 extending in a direction of travel 18 of the motor vehicle 2 .

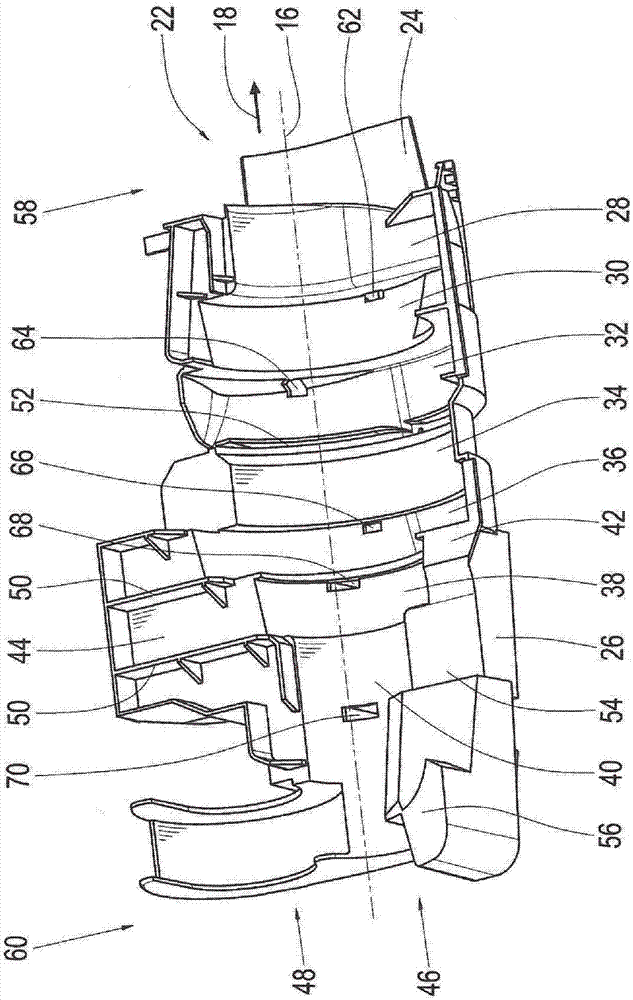

[0023] figure 2 Shown is a lubricant guide hood 22 arranged within the transmission 6 (not shown here), wherein the direction to the rotating components not shown here to be accommodated in the lubricant guide hood 22 is shown and a surface area 26 pointing in the direction of the surrounding transmission housing, also not shown here. The surface region 24 pointing in the direction of the rotating component is divided into a plurality of sections 28 , 30 , 32 , 34 , 36 , 38 , 40 . The recesses in the sections 28 to 40 have different diameters and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com