Pump gear

A transmission device, pump head technology, applied in the direction of pumps, components of pumping devices for elastic fluids, multi-cylinder pumps, etc., can solve the limitation of proximity, the high cost of laying pipelines, and the difficulty of satisfying pump location requirements And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

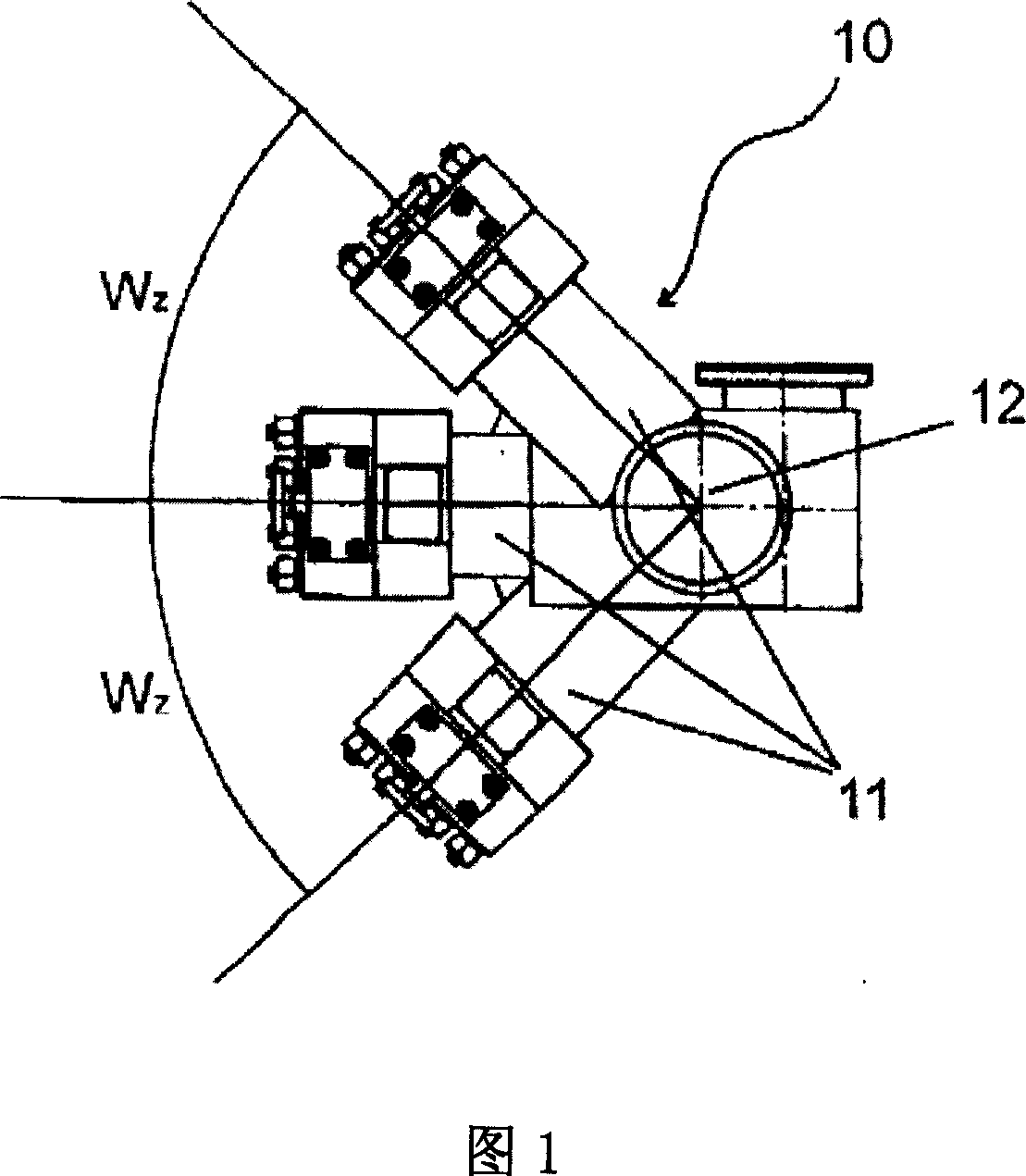

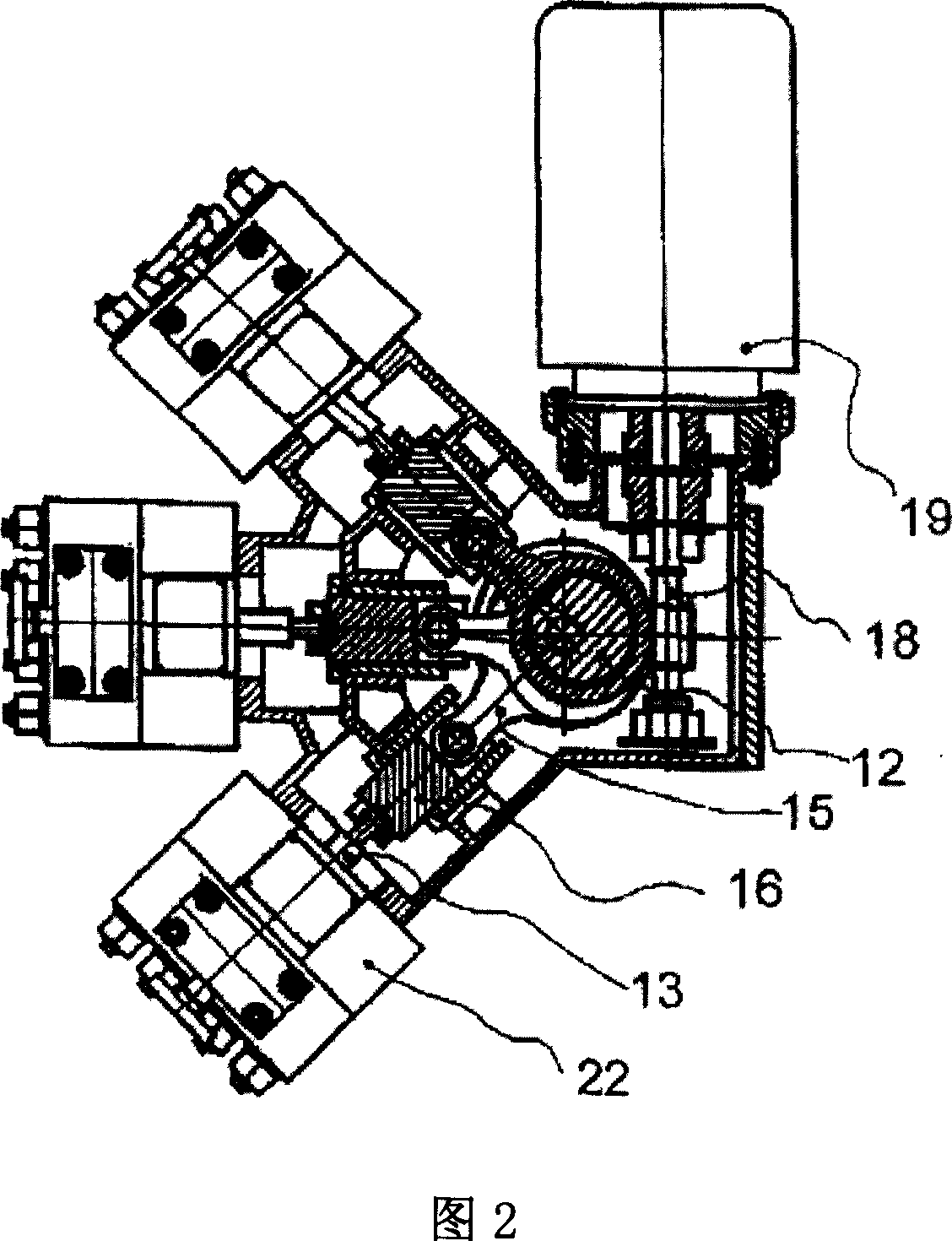

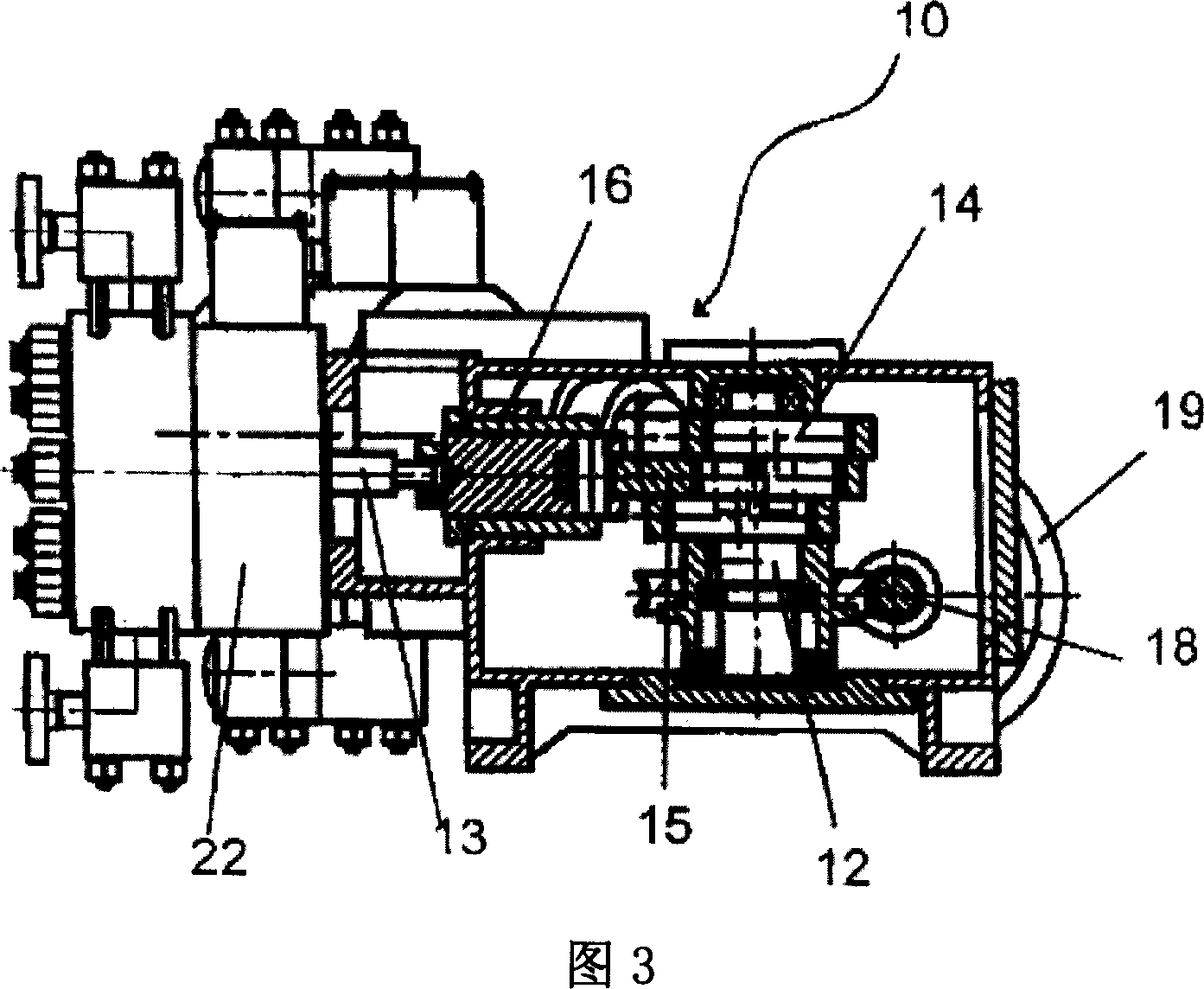

[0037] FIG. 1 shows a possible geometric arrangement of a pump drive 10 according to the invention with three cylinders 11 , viewed from above. The cylinders 11 are shown horizontally radially away from the vertically oriented crankshaft 12 . In this embodiment, the cylinders 11 are arranged symmetrically and each include a rotation angle W relative to one another in projection on a plane perpendicular to the crankshaft 12 z . A pump drive 10 with the same geometrical profile is depicted in more detail in FIG. 2 . The sectional plane of the drawing extends through the uppermost connecting rod 15 . In contrast, the two further connecting rods 15 are supported on the crankshaft 12 directly below the uppermost connecting rod 15 without spacing therebetween. The vertically arranged crankshaft 12 is driven by a drive motor 19 via a horizontally arranged worm gear 18 . On the crankshaft 12, three connecting rods 15 are supported on the respective crank 14, respectively. At thei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com