Formwork strengthening and supporting system of inverted-horn-shaped arc-shaped shear wall

A formwork reinforcement and shear wall technology, which is applied in the connection of formwork/formwork/work frame, the preparation of building components on site, construction, etc., can solve the difficulty in the construction of large overhangs and large arcs , construction period and large construction costs, etc., to achieve the effect of reducing support and reducing the cost of measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

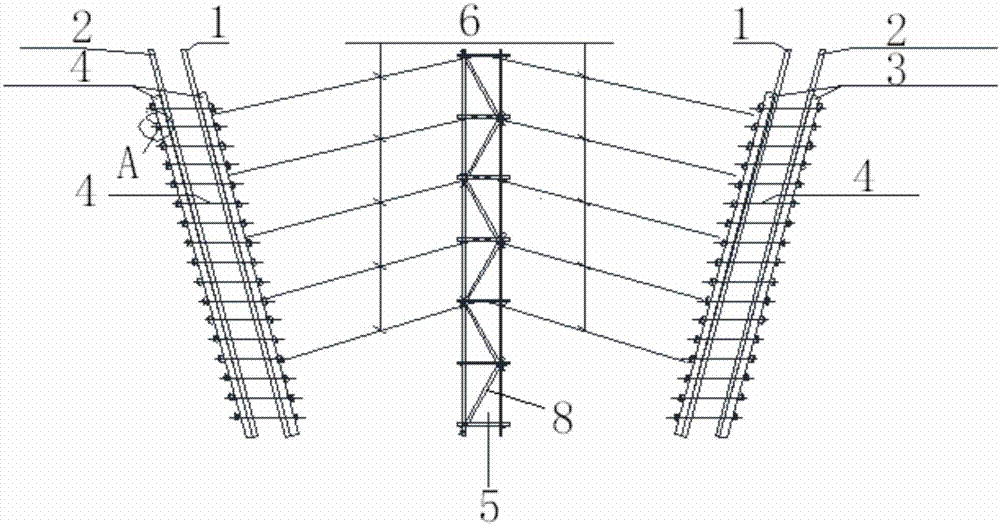

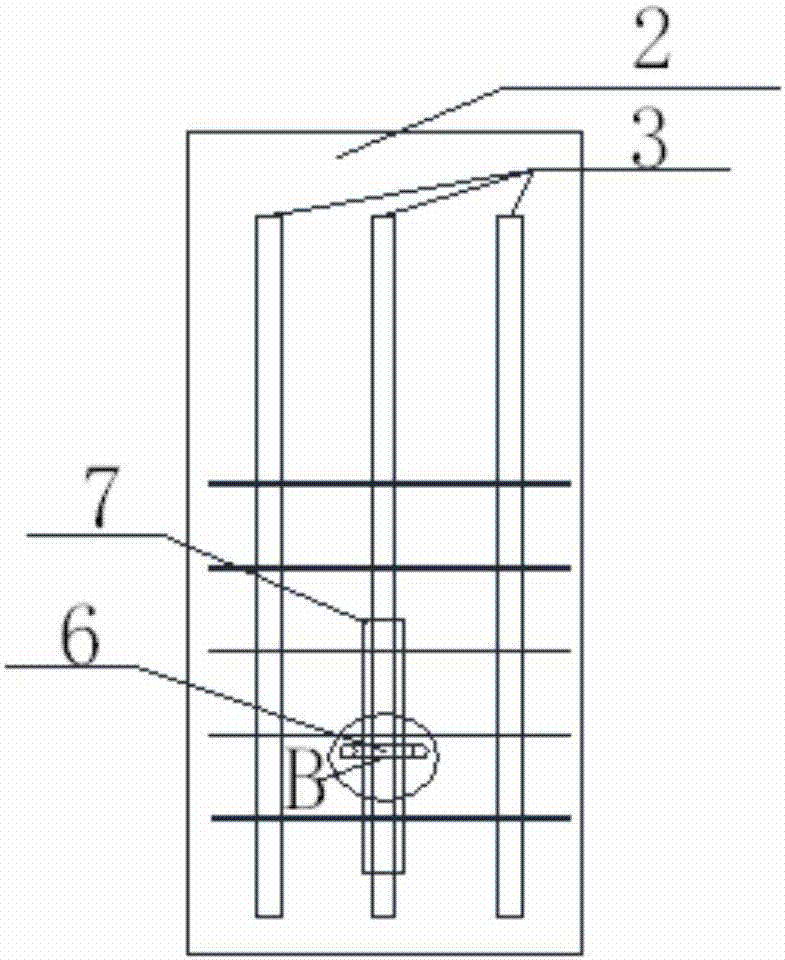

[0027] Such as Figure 1-5 As shown, a formwork reinforcement support method for an inverted flared arc shear wall includes the following steps:

[0028] 1. Lay out the line according to the drawing size and install the inner formwork 1, which is temporarily fixed by the top floor formwork;

[0029] 2. Then install the shear wall reinforcement;

[0030] 3. After the concealed acceptance of the steel bar is completed, install the outer formwork 2. During the installation of the outer formwork 2, use the steel wire to temporarily fix the inner formwork 1 and steel bars;

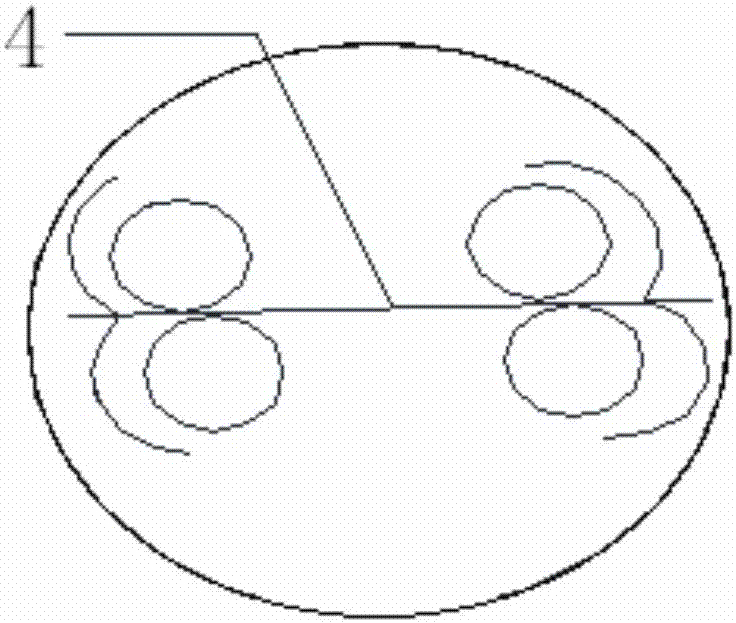

[0031] 4. Install the square timber corrugated 3 on the inner formwork 1 and the outer formwork 2, and install a number of pairs of tension bolts 4 at intervals, and fix the square timber corrugated 3, the inner formwork 1 and the outer formwork 2 through the tension bolts 4. 4 There are arcs made of steel bars with a diameter of 25mm on the inside of the mountain-shaped cards on both sides;

[0032] 5. Use a scaffold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com