Oil-storage high-speed dial linking sewing machine

A technology of sewing machine and oil storage, which is applied to sewing machine components, sewing machine thread take-up devices, sewing machine control devices, etc. It can solve the problems that users forget to refuel, the oil volume is difficult to control, and the service life is affected, so as to prevent thread jumping , Easy to operate, stable operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

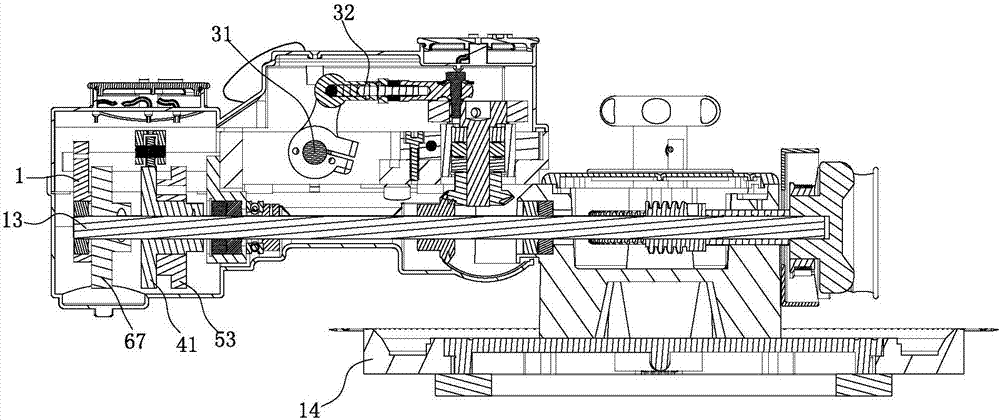

[0032] See Figure 1-10 As shown, it is an oil storage high-speed disc sewing machine, which includes: a vehicle platform 11, a bracket 12 installed on the side of the vehicle platform 11, and a transmission spindle 13 passing through the vehicle platform 11 and the bracket 12, and installed on the vehicle platform. 11 outside and used to drive the power unit 2 of the transmission spindle 13 to rotate, the dial 14 installed under the car platform 11, the worm gear assembly 15 installed in the car platform 11 and used to drive the dial 14 to rotate, installed on the outside of the bracket 12 And the hook assembly 16 that cooperates with the dial 14, is installed in the support 12 and is used to drive the eccentric wheel driving device 3 that the hook assembly 16 swings, is installed in the thread take-up device 4 in the support 12, is installed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com