Anti-attaching plate

An anti-sticking and anti-sticking technology, which is applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problems of increased pressure and affecting cleaning, so as to reduce warpage and solve warpage The effect of increasing and releasing the stress of the film layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following description of the embodiments refers to the accompanying drawings to illustrate specific embodiments in which the invention may be practiced. The directional terms mentioned in the present invention, such as "up", "down", "front", "back", "left", "right", "top", "bottom", etc., are only for reference to the attached drawings. direction. Therefore, the directional terms used are used to illustrate and understand the present invention, but not to limit the present invention.

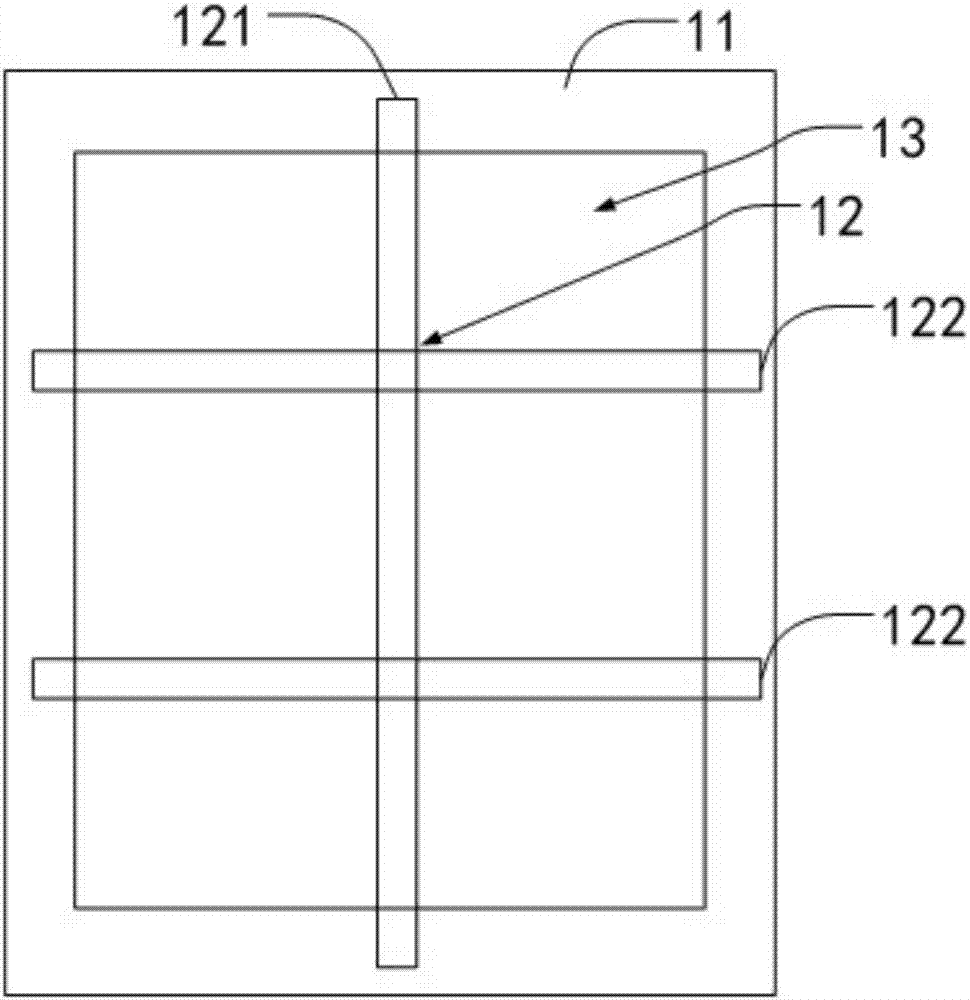

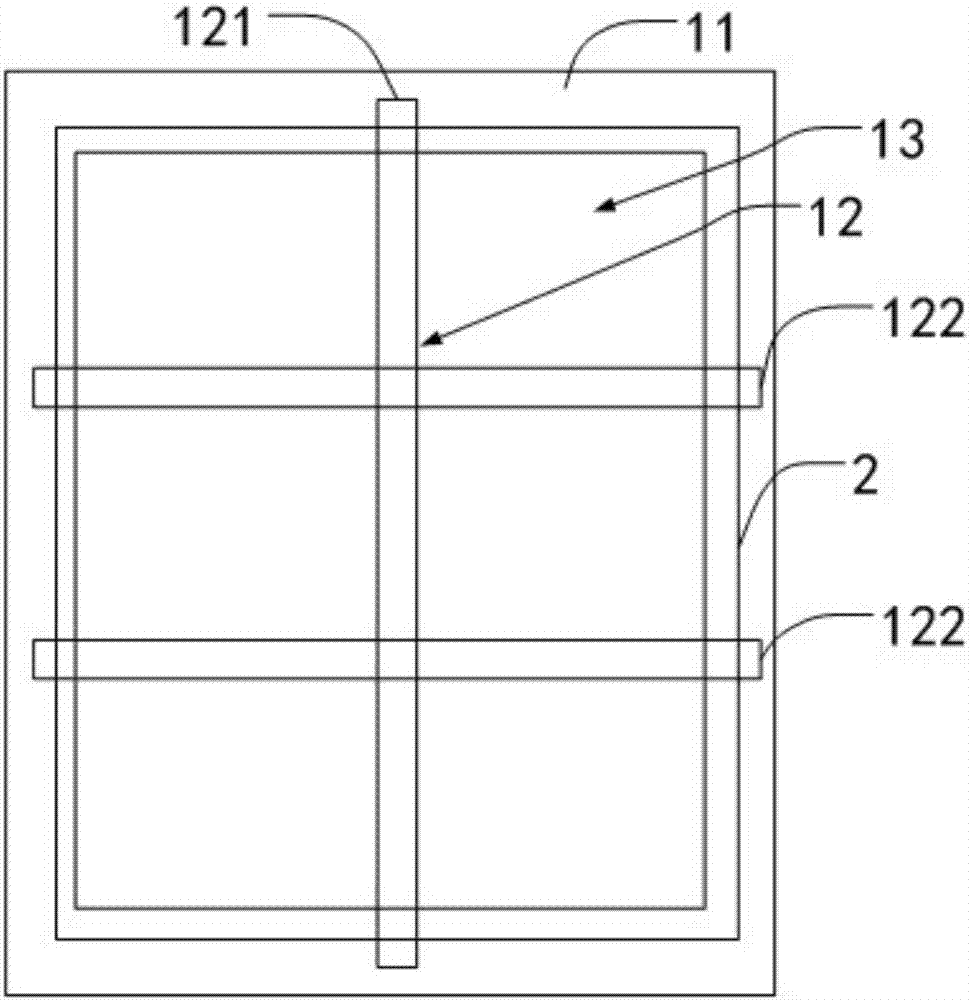

[0026] Examples such as figure 1 As shown, an anti-slip board includes a motherboard 11 and an anti-strip 12 .

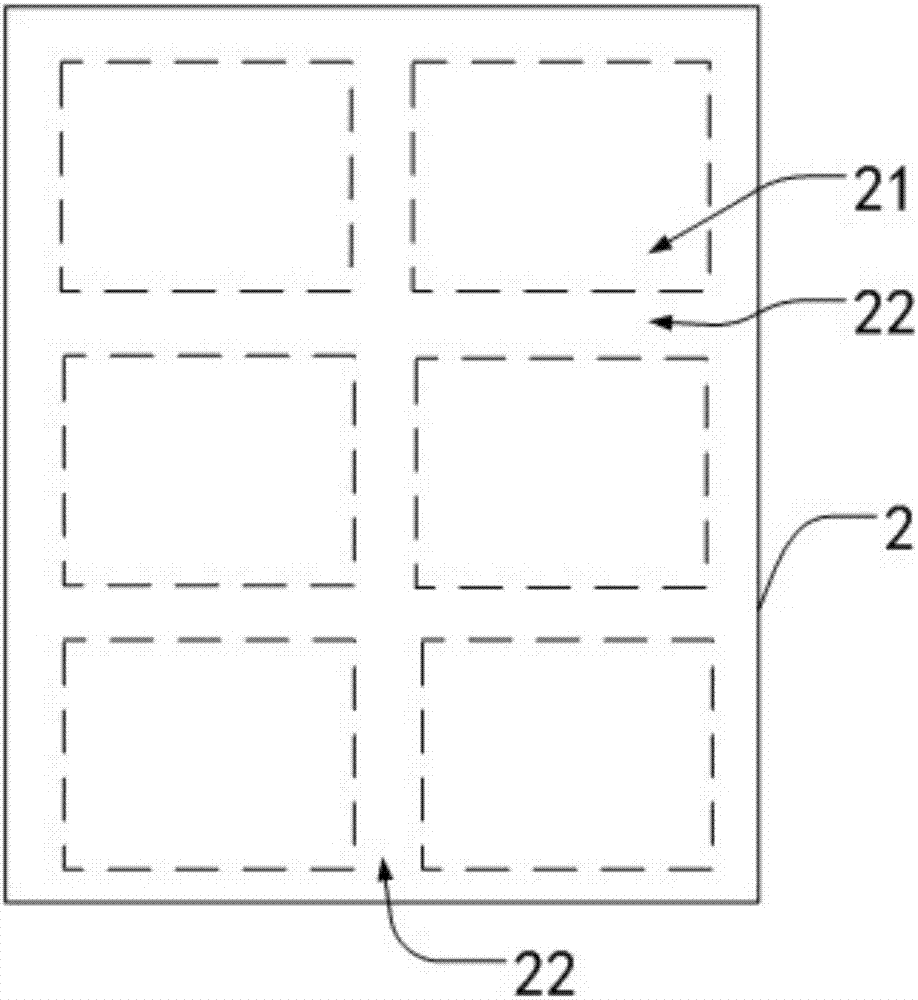

[0027] In this embodiment, a sputtering zone is provided in the middle of the motherboard 11 ; the anti-strips 12 are assembled on the motherboard 11 and divide the sputtering zone into a plurality of independent sputtering zones 13 .

[0028] Wherein, in this embodiment, the anti-stripping strip 12 includes a first strip body 121 and a second strip body 122, and the fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com