Lubiprostone refining method

A technology of lubiprostone and organic solvents, which is applied in the field of refined lubiprostone, can solve the problems of reducing production costs, and achieve the effects of simple operation, stable properties and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

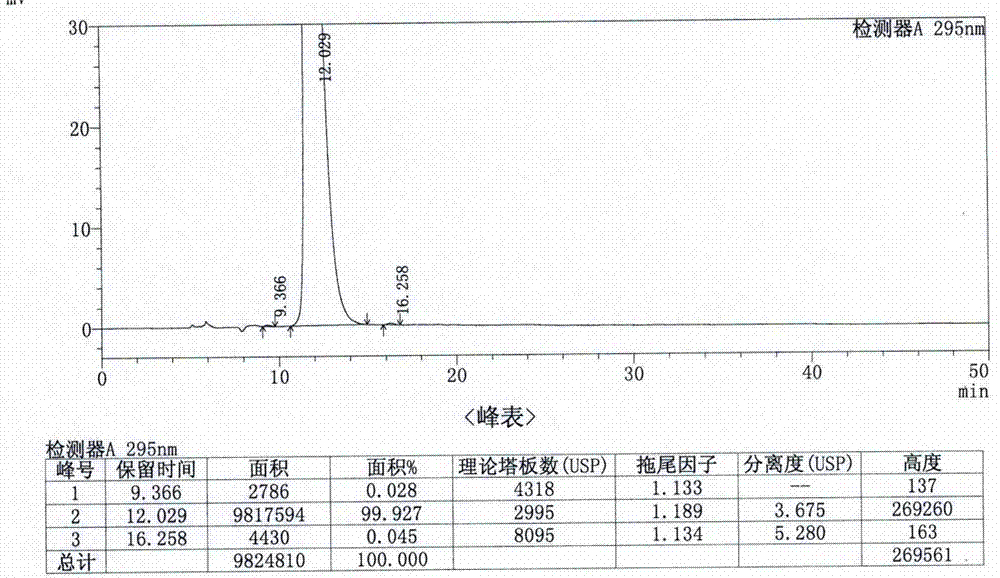

[0014] Put crude lubiprostone (100g) in isopropyl acetate (200mL), stir at 20-30°C to dissolve it. After dissolving, add activated carbon (5g) and stir at 20-30°C for 30 minutes. After stirring, filter out the activated carbon and rinse the filter cake with isopropyl acetate (50mL). Slowly add octane to the filtrate, crystallize at 15~25°C for 4 hours, filter with suction, and wash the filter cake with octane (200mL). The filter cake was vacuum-dried for 4 hours to obtain 95.3 g of off-white crystalline powder with a yield of 95.3% and a purity of 99.67%.

Embodiment 2

[0016] Put crude lubiprostone (10g) in acetone (35mL), stir at 20-30°C to dissolve it. After dissolution, tert-butyl methyl ether (100 mL) was slowly added. After the addition, keep stirring for 8 hours. After suction filtration, the filter cake was rinsed with methyl tert-butyl ether (20 mL), and dried at 25-35°C for 4 hours to obtain 7.95 g of off-white crystalline powder with a yield of 79.5% and a purity of 99.23.

Embodiment 3

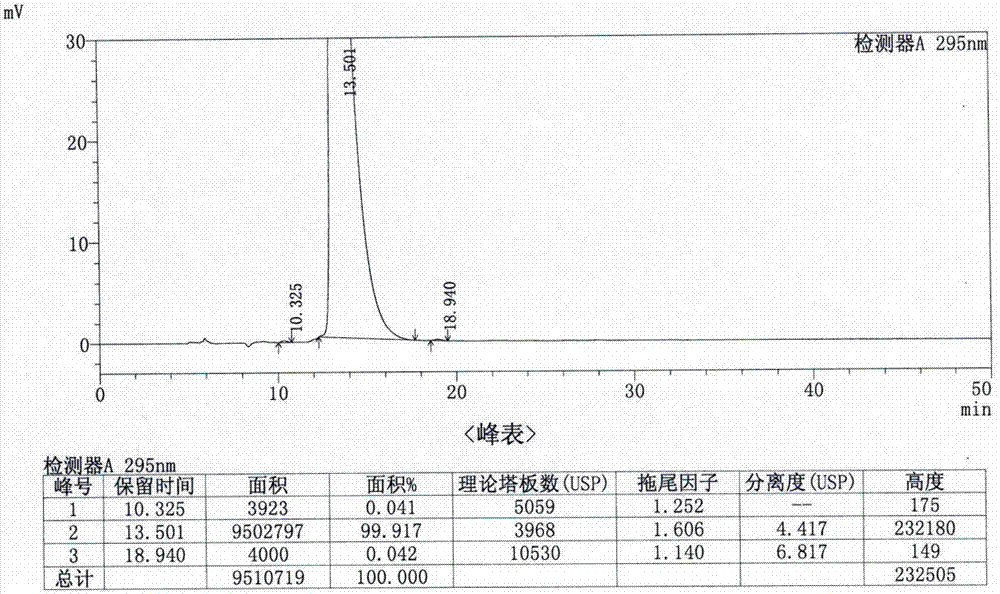

[0018] The crude lubiprostone (50g) was placed in ethyl acetate (100mL), stirred at 20-30°C to dissolve it. After dissolving, add activated carbon (5g), stir at 20-30°C for 30 minutes, filter the activated carbon, and rinse the filter cake with ethyl acetate (10mL). Isooctane (1320 mL) was slowly added to the filtrate, and after the addition was completed, it was incubated and crystallized for 2 hours. Suction filtration, rinse the filter cake with isooctane (100mL), and dry at 25-35°C for 6 hours to obtain 43.2% off-white crystalline powder with a yield of 86.4% and a purity of 99.02%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com