A method for preparing iron oxide black and calcium chloride by using waste acid from iron and steel plant

An iron oxide black, iron and steel plant technology, applied in the direction of iron oxide/iron hydroxide, ferrous oxide, calcium/strontium/barium chloride, etc., can solve the problem of harsh reaction conditions of iron oxide, and achieve heavy metal Low content, mild reaction conditions, and the effect of reducing displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

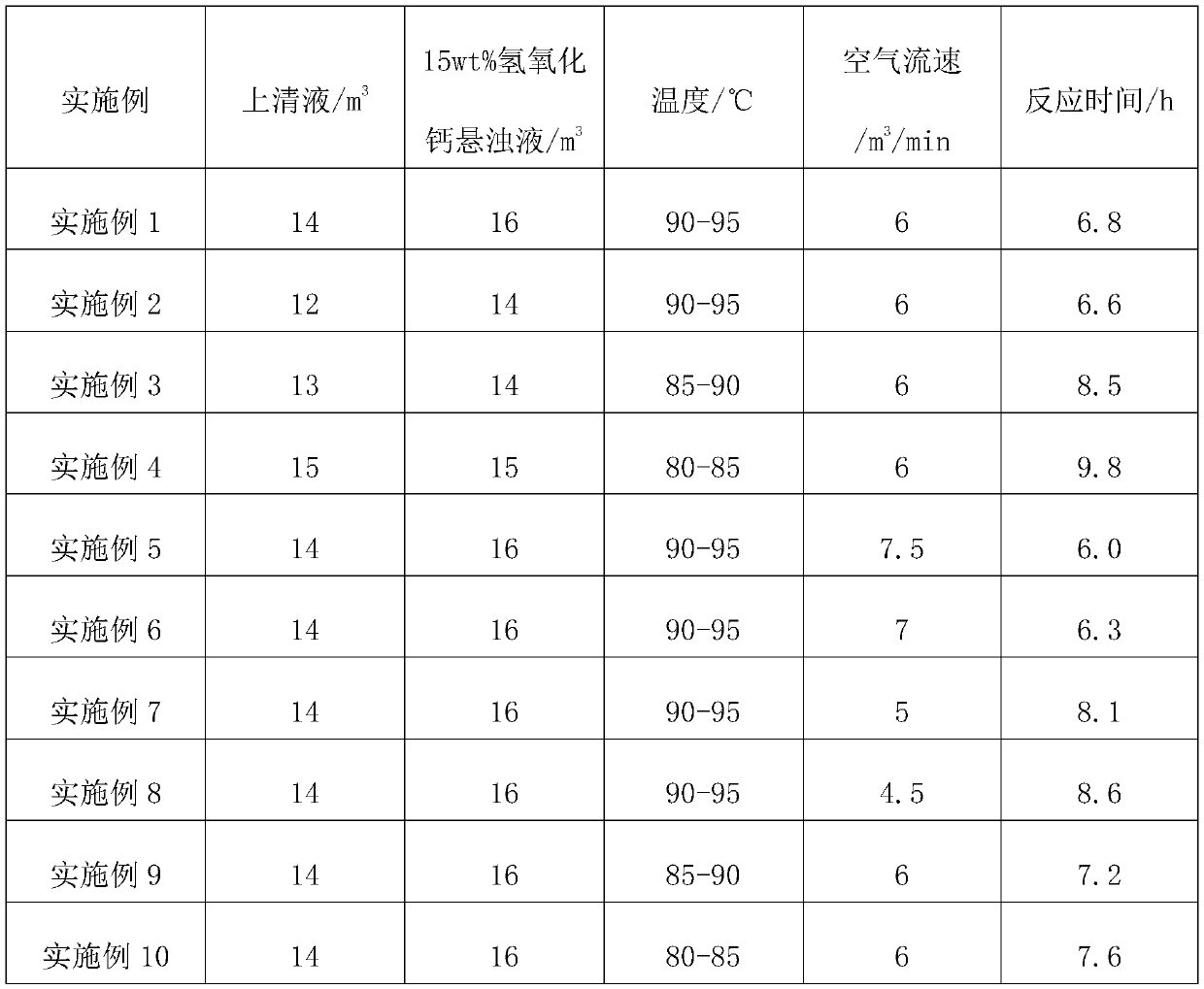

[0024] Embodiment 1: A method for preparing iron oxide black and calcium chloride by using waste acid from iron and steel plants, comprising the following steps: S1: adding clean iron sheets to the waste acid from iron and steel plants to fully react with hydrochloric acid to make excess iron sheets, and then adding The coagulant aid improves the sedimentation speed, and the coagulant aid is allowed to stand for clarification. The concentration of the coagulant aid added is 8ppm; in the present embodiment, the coagulant aid adopts polyacrylamide;

[0025] S2: Take 14m 3 The supernatant was added to 50m 3 In the reactor, add 16m 3 Calcium hydroxide suspension with a mass fraction of 15 wt%, adjust the pH value to 6-9, and heat up to 95°C;

[0026] S3: Oxidation by blasting air, the air velocity is 6m 3 / min, when the pH is read from the pH meter and is less than 6.5 during the oxidation process, immediately add a calcium hydroxide suspension with a mass fraction of 15wt%, an...

Embodiment 2

[0029]Embodiment 2: a kind of method adopting iron and steel plant waste acid to prepare iron oxide black and calcium chloride comprises the steps:

[0030] S1: Add clean iron sheet to the waste acid of the iron and steel plant and fully react with hydrochloric acid to make the iron sheet excessive. After the reaction, add a coagulant to increase the precipitation speed, and let it stand for clarification. The concentration of the coagulant is 5ppm; in this embodiment, Polyacrylamide is used as coagulant aid;

[0031] S2: take 12m 3 The supernatant was added to 50m 3 Reactor, add 14m 3 Calcium hydroxide suspension with a mass fraction of 15 wt%, adjust the pH value to 6-9, and heat up to 95°C;

[0032] S3: Oxidation by blasting air, the air velocity is 6m 3 / min, when the pH is read from the pH meter and is less than 6.5 during the oxidation process, immediately add a calcium hydroxide suspension with a mass fraction of 15wt%, and the amount added each time is 0.5m 3 ; Ke...

Embodiment 3

[0035] Embodiment 3: a kind of method adopting iron and steel plant waste acid to prepare iron oxide black and calcium chloride comprises the steps:

[0036] S1: Add clean iron sheet to the waste acid of iron and steel plant and fully react with hydrochloric acid to make the iron sheet excessive. After the reaction, add a coagulant to increase the precipitation speed, and let it stand for clarification. The concentration of the coagulant is 10ppm; in this embodiment, The coagulant is sodium carboxymethyl cellulose;

[0037] S2: take 13m 3 The supernatant was added to 50m 3 Reactor, add 14m 3 The mass fraction is 15wt% calcium hydroxide suspension, the pH value is adjusted to 6-9, and the temperature is raised to 90°C;

[0038] S3: Oxidation by blasting air, the air velocity is 6m 3 / min, when the pH is read from the pH meter and is less than 6.5 during the oxidation process, immediately add a calcium hydroxide suspension with a mass fraction of 15wt%, and the amount added ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com