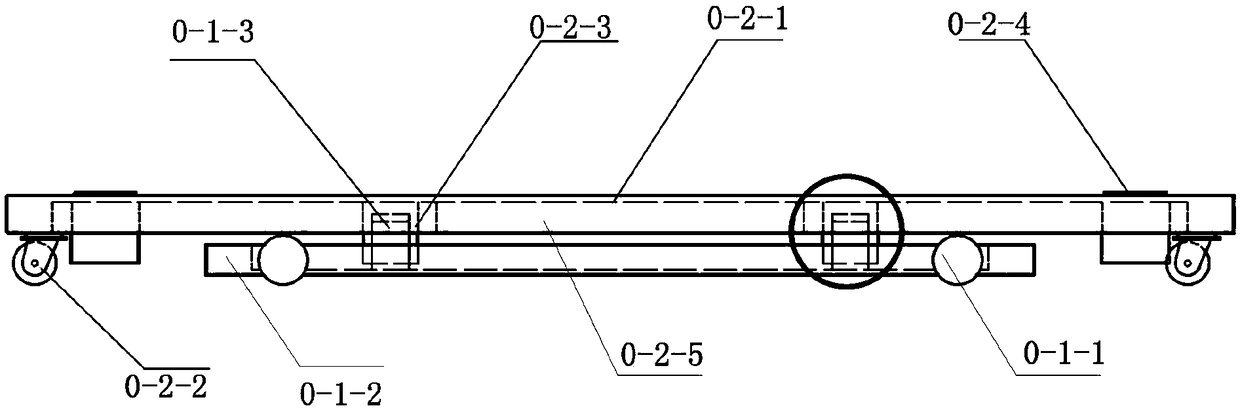

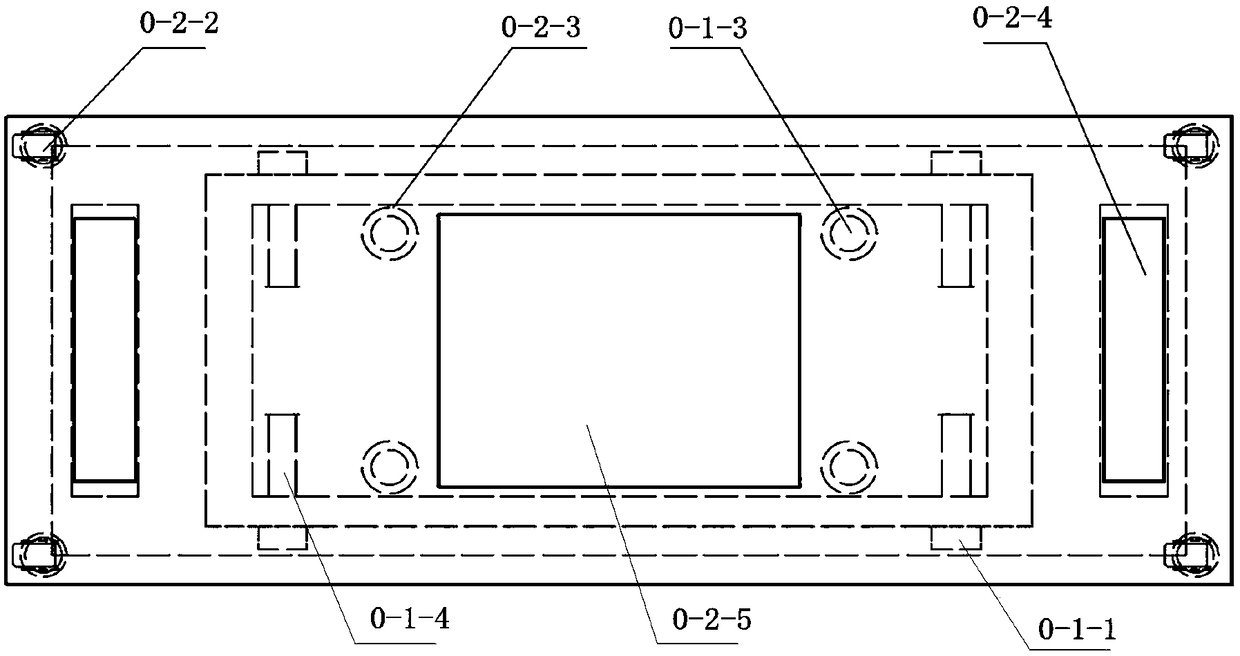

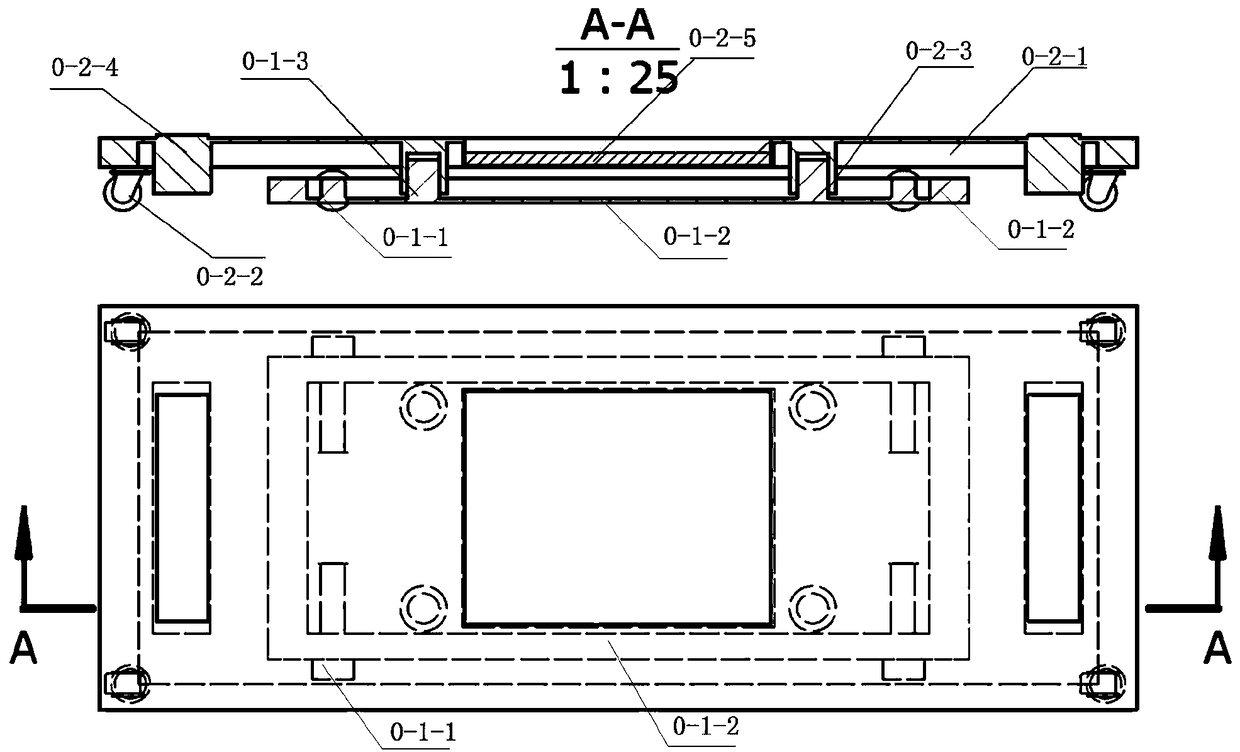

A double-deck AGV vehicle, its driving method, and robot handling system

A double-layer, push mechanism technology, applied in the fields of handling AGV, warehousing and logistics, and intelligent parking, it can solve the problems of height and load wheel diameter restrictions, and achieve the effect of movement flexibility and high movement efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is described in detail below in conjunction with accompanying drawing:

[0043] Design principle of the present invention is:

[0044] 1. The principle that "push and walk" is much easier than "hold and walk". There are many examples like this in daily life: if the suitcase, if no wheels are installed to the suitcase, then the suitcase is directly placed on the ground to drag or manually lift the suitcase and walk will make people feel very tired. Dragging on the ground is a kind of sliding friction. If wheels are installed on the suitcase, the sliding friction will be changed into rolling friction. Rolling friction will be much easier than sliding friction. The same is true for robots. When the load of the AGV exceeds 2 tons and the height of the car body is required to be limited to a low range, simply adding omni-directional wheels to each set of mecanum wheels is like replacing one by two people. People lift a very heavy box case, although ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com