Construction process for lower component of seaborne booster station

An offshore booster station and component technology, which is applied in the directions of installing/supporting the configuration of wind turbines, etc., can solve the problems of weakening the connection accuracy and supportability of the lower component, difficult construction of the lower component, and low rolling and cutting requirements. Guarantee long-term operation and maintenance, ensure welding quality and welding accuracy, and ensure the effect of stable welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following specific examples illustrate the implementation of the present invention. Those familiar with the technology can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

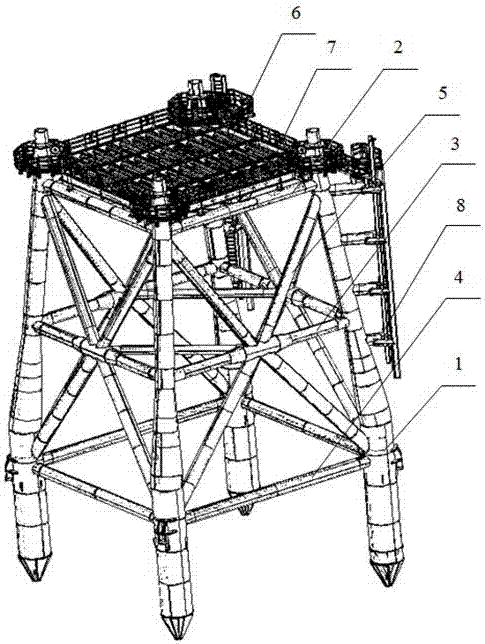

[0017] Such as figure 1 As shown, a construction process of a lower component of a sea lift station is a jacket that is vertically arranged and whose lower end extends to a bearing layer below the seabed. The jacket includes a plurality of steel pipe piles, The steel pipe pile includes a vertical part and an inclined part, the lower end of the inclined part is connected with the upper end of the vertical part, and the upper end of the inclined part is inclined inwardly, and the inclined parts of the plurality of steel tube piles are arranged correspondingly in sequence, At the same time, a first cross brace bar, a second cross brace bar, and a third cross brace bar are set between the upper end positions, the middle positions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com