3D printing molding modular system suitable for automatic production line and using method of 3D printing molding modular system

An automated production line and 3D printing technology, applied in the direction of additive manufacturing, process efficiency improvement, additive processing, etc., can solve the problems of small size, manual work, and inability to adapt to mass production of the production line, so as to achieve high production efficiency and solve equipment problems. The effect of continuous large-scale production and high industrial production value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

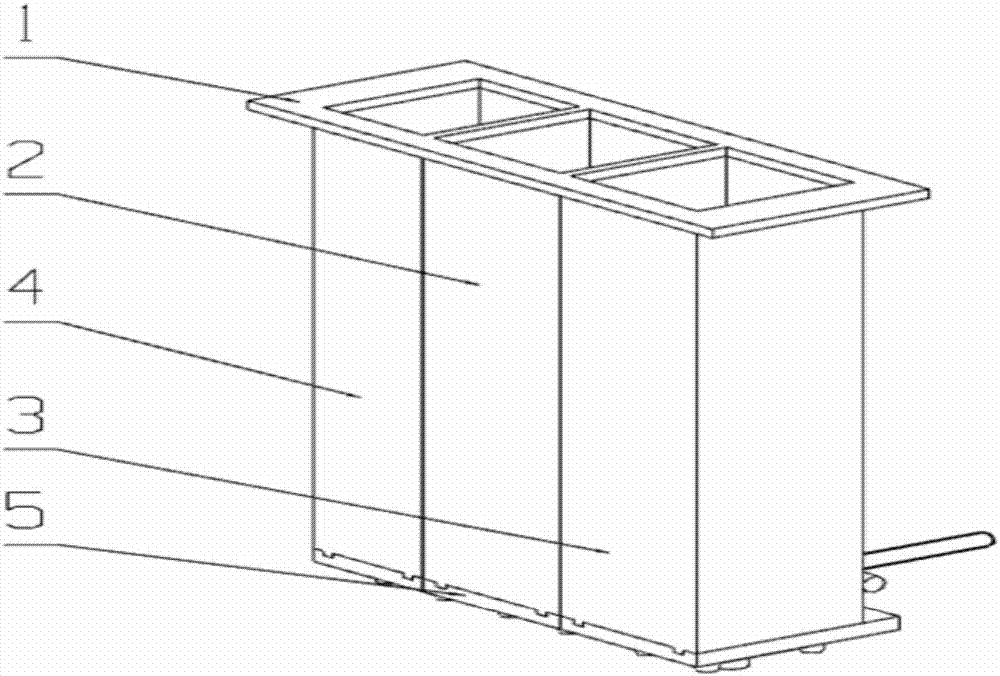

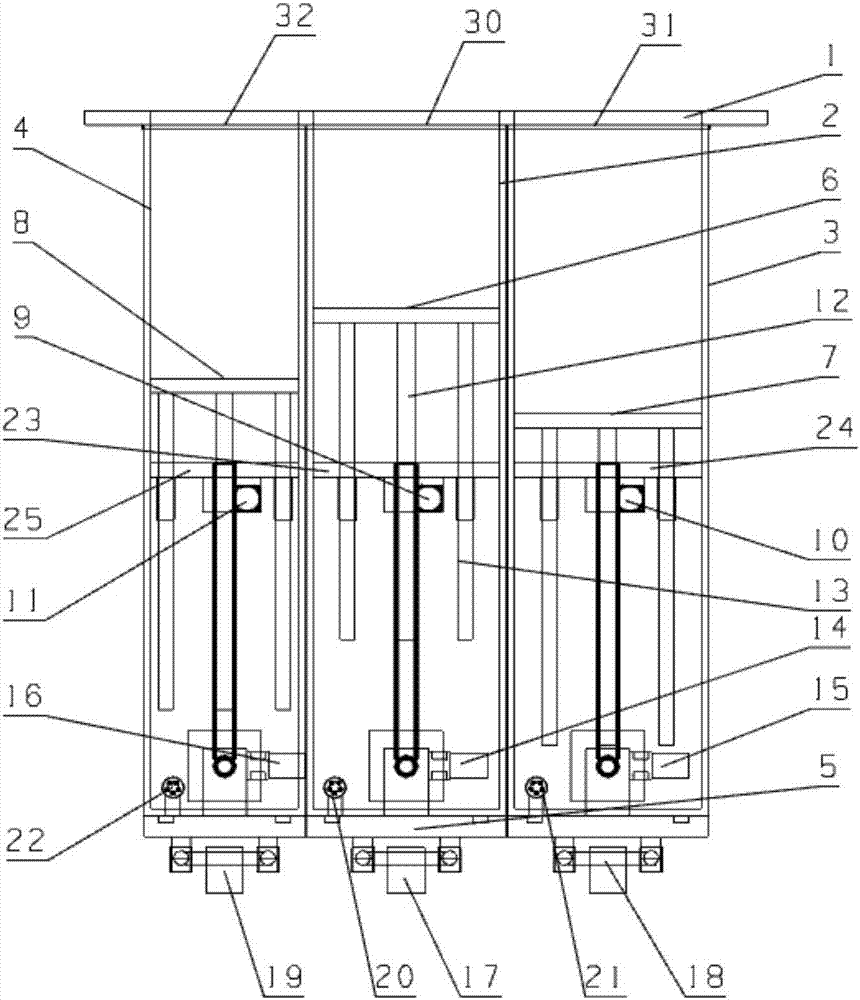

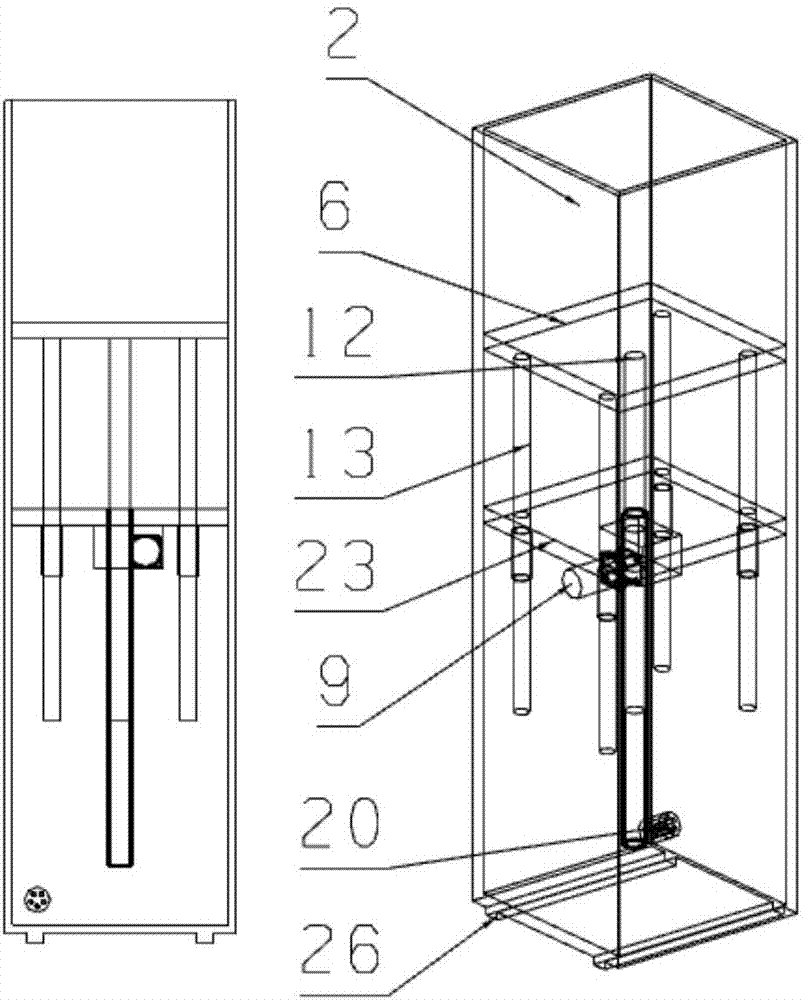

[0025] A modular forming system suitable for 3D printing equipment in an automated production line, comprising a working cabin frame 1, a forming cylinder 2, a material feeding cylinder 3, a collecting cylinder 4, and a lower base 5, characterized in that the working cabin frame 1 and 3D The skeleton of the printing equipment is supported and fixed, and the first pressure sensor 30, the second pressure sensor 31, and the third pressure sensor 32 are respectively installed between the working cabin frame 1 and the lower forming cylinder 2, feeding cylinder 3, and collecting cylinder 4 to form the lower part. Cylinder 2, feeding cylinder 3, and collecting cylinder 4 play the role of limiting and fixing; among them, the internal structure of forming cylinder 2, feeding cylinder 3, and collecting cylinder 4 is the same;

[0026] The internal structure of the form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com