Novel harmful gas adsorbing particle, and preparation method thereof

A technology for harmful gas and adsorption particles, which is applied in the field of new harmful gas adsorption particles and their preparation, and achieves the effects of outstanding nanometer characteristics, remarkable adsorption characteristics, and increased specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

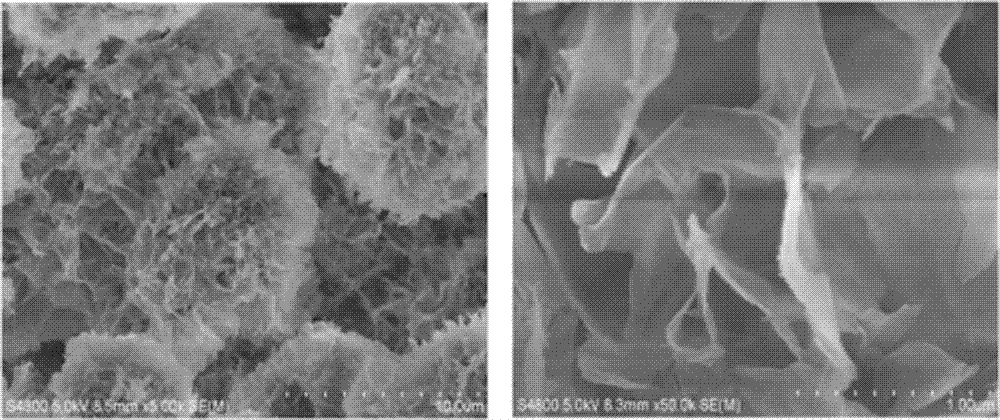

Image

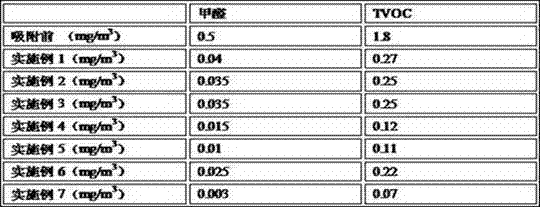

Examples

Embodiment 1

[0037] A new type of harmful gas adsorption particles, including the following raw materials: calcium silicate powder 100kg, photocatalytic nano powder material 0.5kg, modifier 2kg, coagulant 5kg and wetting agent 3kg;

[0038] Among them, the performance requirements of calcium silicate powder are: specific surface area ≥ 350m 2 / g, pore volume ≥ 0.6cm 3 / g, average pore diameter 20-50nm, alkali content Na 2 O ≤ 0.2%; the photocatalytic nano powder material is nano TiO 2 ; The modifying agent is sodium hypochlorite; The coagulating agent is dicalcium silicate; The wetting agent is sodium oleate.

Embodiment 2

[0040] A new type of harmful gas adsorption particles, including the following raw materials: calcium silicate powder 100kg, photocatalytic nano powder material 3kg, modifier 20kg, coagulant 20kg and wetting agent 8kg;

[0041] Among them, the performance requirements of calcium silicate powder are: specific surface area ≥ 350m 2 / g, pore volume ≥ 0.6cm 3 / g, average pore diameter 20-50nm, alkali content Na 2O ≤ 0.2%; the photocatalytic nano-powder material is nano-ZnO; the modifier is potassium permanganate; the coagulant is tricalcium silicate; the wetting agent is ethylene glycol methyl ether .

Embodiment 3

[0043] A new type of harmful gas adsorption particles, including the following raw materials: calcium silicate powder 100kg, photocatalytic nano powder material 1kg, modifier 8kg, dicalcium silicate 4kg, tricalcium silicate 6kg and wetting agent 5kg;

[0044] Among them, the performance requirements of calcium silicate powder are: specific surface area ≥ 350m 2 / g, pore volume ≥ 0.6cm 3 / g, average pore diameter 20-50nm, alkali content Na 2 O ≤ 0.2%; the photocatalytic nano-powder material is nano-SiO 2 ; The modifying agent is chlorine dioxide; The wetting agent is ethylene glycol ether.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com