Plant processing device for circularly extracting natural active components of plant

A technology of active ingredients and cyclic extraction, which is applied in solvent extraction, separation method, solid solvent extraction, etc., can solve the problems of long extraction time of effective ingredients of plants, incomplete analysis of effective ingredients of plants, long time of decoction of plants, etc. , to achieve the effect of improving the utilization rate of plants, facilitating even heating, and reducing the cooking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

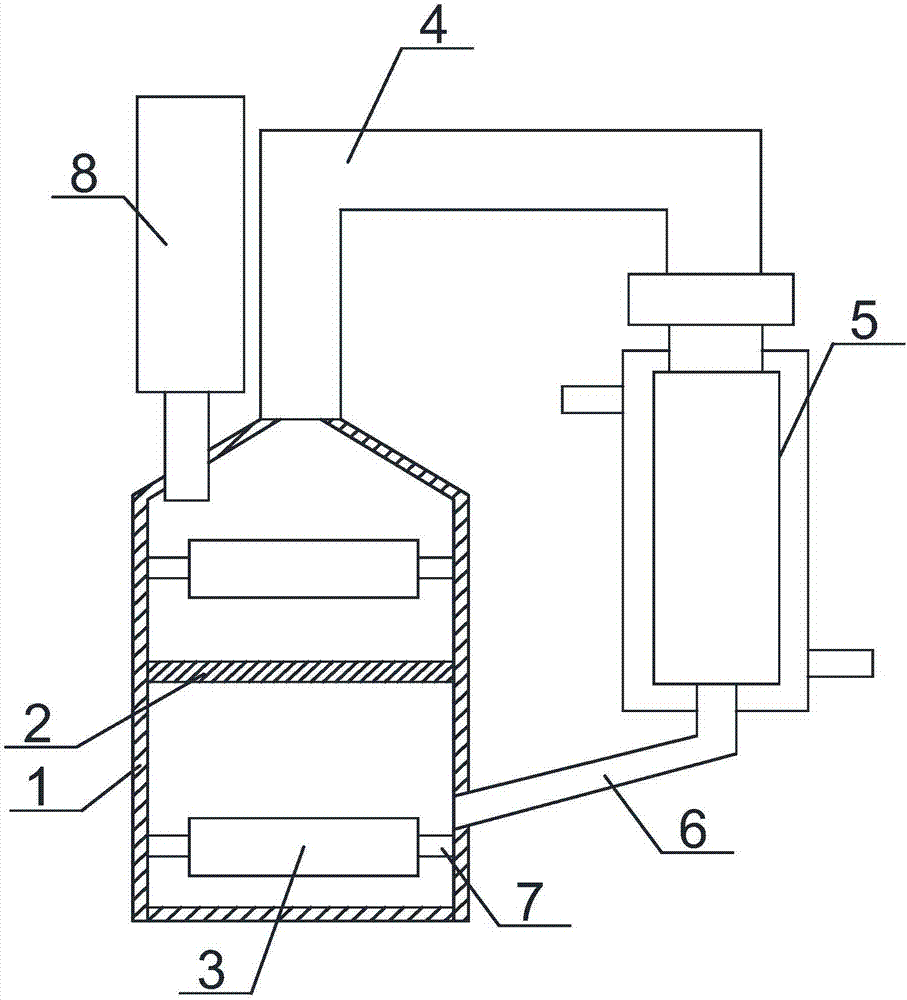

[0022] Such as figure 1 As shown, the plant processing equipment that can recycle extract natural active ingredients of plants in the present invention includes a reaction tank 1, and a horizontal partition 2 is installed inside the reaction tank 1, and the partition 2 divides the reaction chamber of the reaction tank 1 into upper and lower Two sealed cavities, the material cylinder 3 is installed in the two sealed cavities, the wall of the material cylinder 3 is hollowed out, the inner wall of the material cylinder 3 is covered with filter cloth, and the connecting pipe 4 is connected to the top of the reaction tank 1, and the connecting pipe 4 One end of the connecting pipe 4 communicates with the sealed chamber above the partition 2, and the other end of the connecting pipe 4 communicates with a vertically placed condenser tube 5, which is located on one side of the reaction tank 1 and is located at the inclined side of the sealed chamber below the partition 3. Above, the l...

Embodiment 2

[0025] Based on Embodiment 1, the lower wall of the partition 2 is provided with a metal condensation plate. The metal condensing plate is used to recover the active ingredients precipitated by the plants in the sealed cavity under the partition to avoid volatilization of the active ingredients. Aluminum cold plates are generally used.

Embodiment 3

[0027] Based on the above embodiment, a vertically placed water cylinder 8 is connected above the sealed cavity above the partition 2 , and the water outlet of the water cylinder 8 communicates with the sealed cavity above the partition 2 . The outer wall of the water cylinder 8 is provided with scale marks. The water cylinder is used to supply the decoction solvent to the sealed cavity above the bulkhead. The scale line is used for one-time water addition to the sealed cavity above the dose partition to avoid adding too much water and low decoction concentration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com