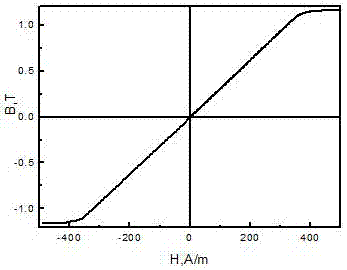

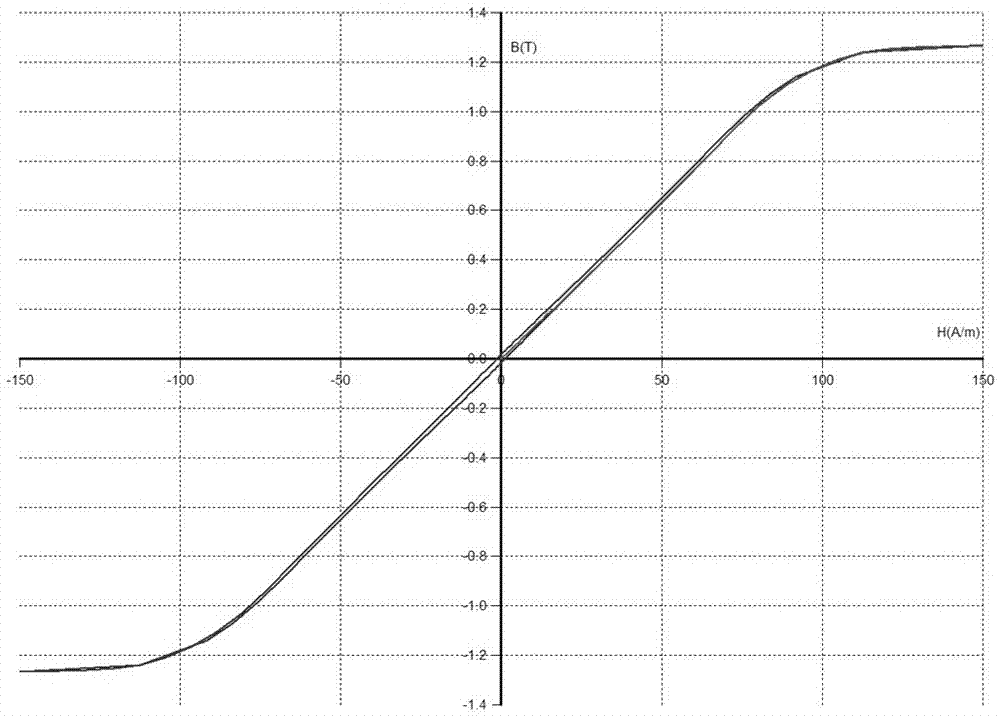

Magnetic core with linear hysteresis loop

A technology of hysteresis loop and magnetic core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A magnetic core with a linear hysteresis loop, including a magnetic core body, the magnetic core body is made of iron-based nanocrystalline soft magnetic alloy, and the iron-based nanocrystalline soft magnetic alloy is composed of the following components in atomic ratio: 72.7 parts of iron , 13.5 parts of silicon, 5.5 parts of boron, 3 parts of niobium, 1.5 parts of vanadium, 1 part of copper, 2 parts of nickel and 0.5 parts of cobalt;

[0035] The above-mentioned preparation method of a magnetic core with a linear hysteresis loop, the steps are as follows:

[0036] S1. The amorphous thin ribbon having the above-mentioned iron-based nanocrystalline soft magnetic alloy composition is prepared by the single-roller spinning method, and the casting temperature is 1420° C. when spraying the ribbon;

[0037] S2, winding the amorphous thin strip into a magnetic core;

[0038]S3. Carry out crystallization annealing treatment in a vacuum environment, keep warm at 470°C for 120...

Embodiment 2

[0041] A magnetic core with a linear hysteresis loop, including a magnetic core body, the magnetic core body is made of iron-based nanocrystalline soft magnetic alloy, and the iron-based nanocrystalline soft magnetic alloy is composed of the following components in atomic ratio: 74 parts of iron , 14.5 parts of silicon, 5.8 parts of boron, 2.3 parts of niobium, 1 part of vanadium, 1 part of copper, 1 part of nickel and 0.4 parts of cobalt;

[0042] The above-mentioned preparation method of a magnetic core with a linear hysteresis loop, the steps are as follows:

[0043] S1. The amorphous thin ribbon having the above-mentioned iron-based nanocrystalline soft magnetic alloy composition is prepared by the single-roller stripping method, and the casting temperature is 1400° C. when spraying the ribbon;

[0044] S2, winding the amorphous thin strip into a magnetic core;

[0045] S3. Carry out crystallization annealing treatment in a vacuum environment, hold at 475°C for 120 minute...

Embodiment 3

[0048] A magnetic core with a linear hysteresis loop, including a magnetic core body, the magnetic core body is made of iron-based nanocrystalline soft magnetic alloy, and the iron-based nanocrystalline soft magnetic alloy is composed of the following components in atomic ratio: 72.6 parts of iron , 15.5 parts of silicon, 7.2 parts of boron, 2.8 parts of niobium, 1.2 parts of vanadium, 1 part of copper, 0.5 parts of nickel and 0.2 parts of cobalt;

[0049] The above-mentioned preparation method of a magnetic core with a linear hysteresis loop, the steps are as follows:

[0050] S1. The amorphous thin ribbon having the above-mentioned iron-based nanocrystalline soft magnetic alloy composition is prepared by the single-roller spinning method, and the casting temperature is 1380° C. when spraying the ribbon;

[0051] S2, winding the amorphous thin strip into a magnetic core;

[0052] S3. Carry out crystallization annealing treatment in a vacuum environment, keep warm at 480°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Residual magnetic induction | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com