Display substrate and preparing method thereof and display device

A technology of display substrate and display structure, applied in the direction of identification devices, instruments, etc., can solve the problems of low bonding yield and uneven stress, and achieve the effect of avoiding the phenomenon of IC short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

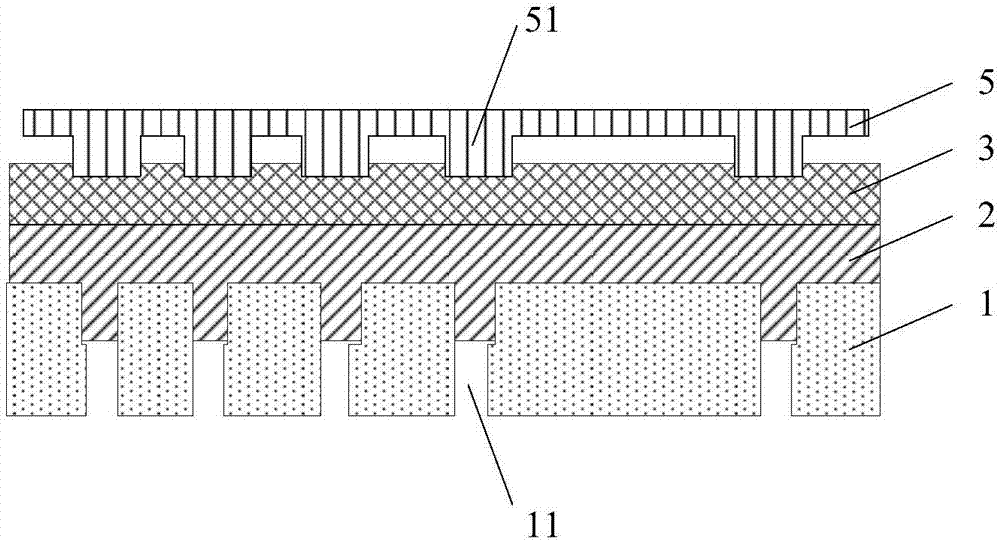

[0027] Aiming at the problem that the IC is directly crimped on the flexible display structure in the COP bonding process, the hot pressing method will cause the deformation and sag of the adhesive in the back film of the flexible display structure located at the protruding contact position of the IC. This embodiment provides a display The substrate and the corresponding preparation method can effectively improve the bonding yield of the flexible display structure, relieve the flow of the adhesive to cause the breakage of the surrounding lines, and the accumulation of particles in the sunken position, and avoid the risk of short circuit.

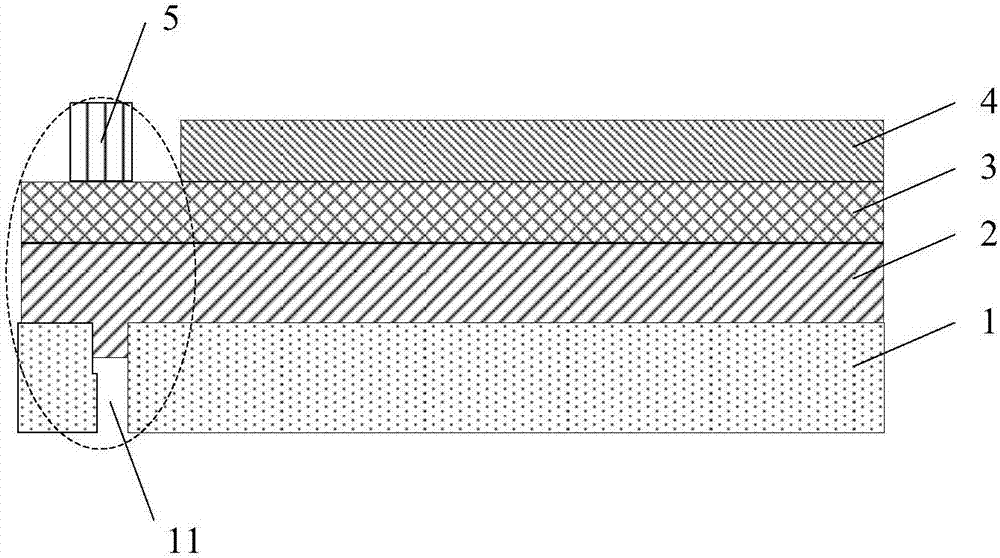

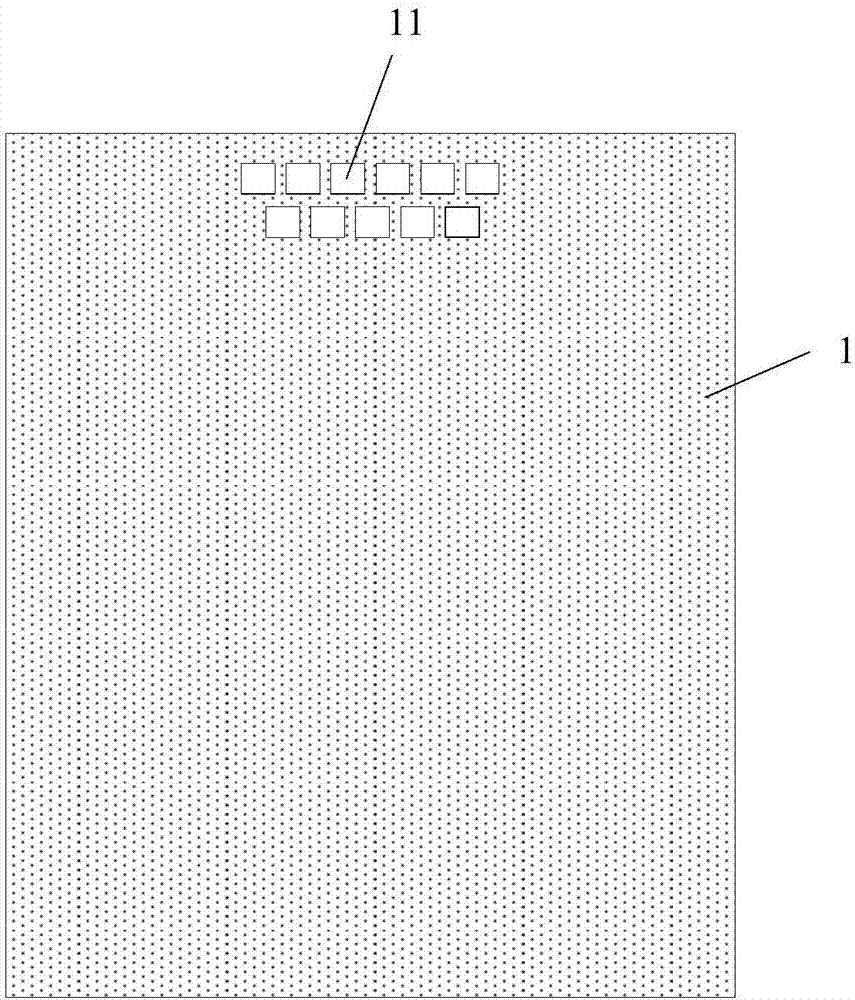

[0028] Such as figure 1 with figure 2 As shown, the display substrate includes a display structure 3, and an electronic device 5 and a base film 1 disposed on both sides of the display structure 3, wherein the display structure 3 and the base film 1 are connected by an adhesive 2, and the base film 1 is placed on the A dredging hole 11 is ...

Embodiment 2

[0058] This embodiment provides a display device, which includes the display substrate of Embodiment 1.

[0059] The display device can be: desktop computer, tablet computer, notebook computer, mobile phone, PDA, GPS, vehicle display, projection display, video camera, digital camera, electronic watch, calculator, electronic instrument, instrument, LCD panel, electronic paper, TV Computers, monitors, digital photo frames, navigators and any other products or components with display functions can be applied to multiple fields such as public display and virtual display.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com