Underground coal gasification deep hole ignition system and method

An underground gasification and ignition system technology, applied in coal gasification, underground mining, construction, etc., can solve the problems of burnout, igniter contact, and inability to ignite coal seams, and achieve the effect of avoiding impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

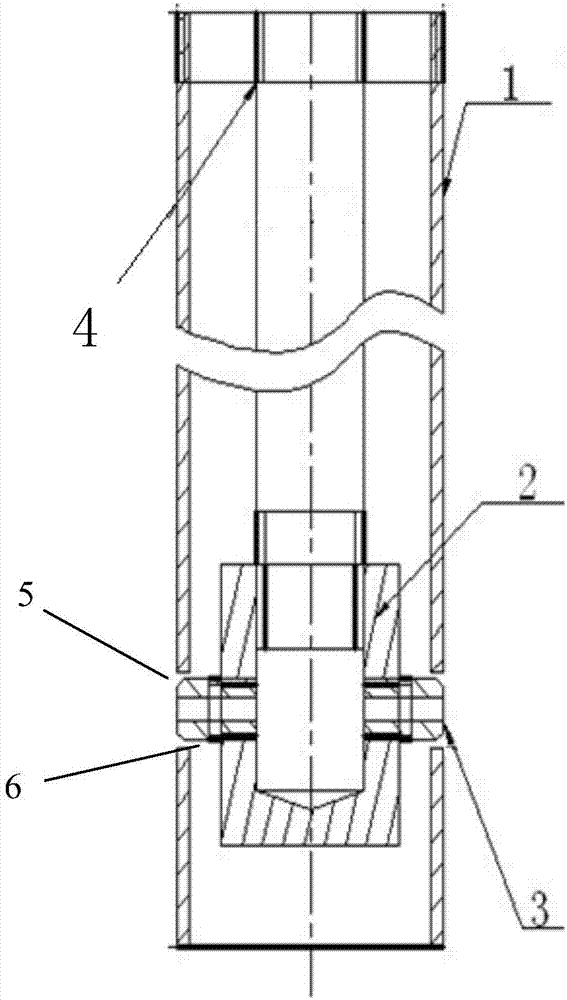

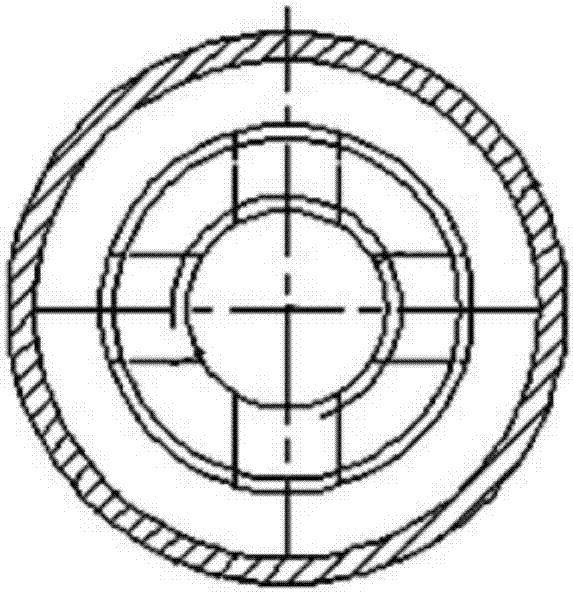

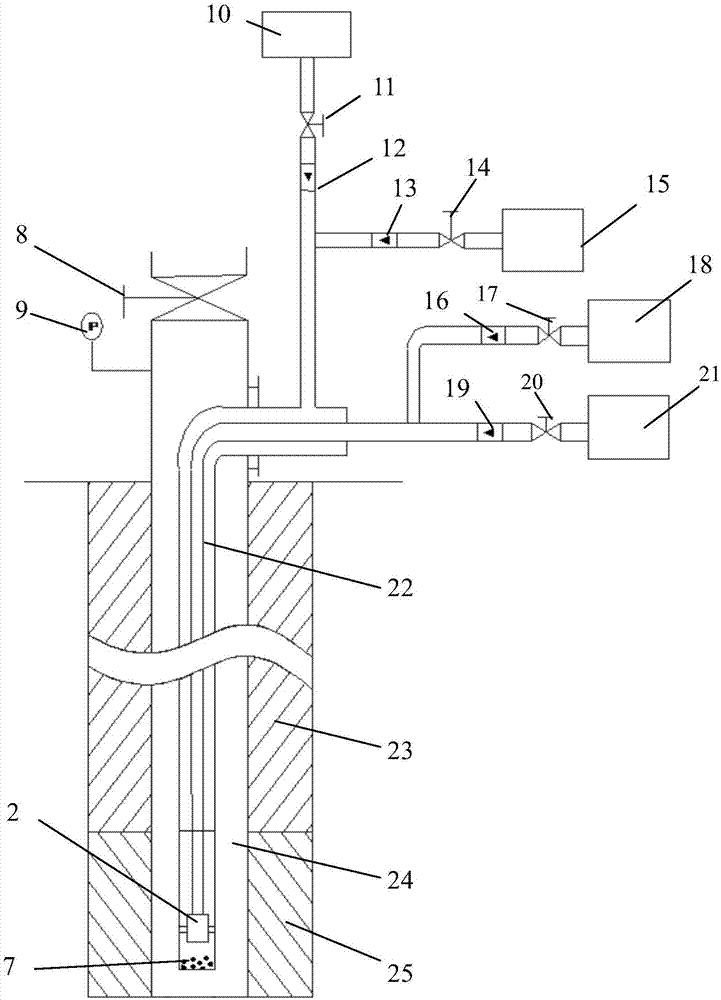

[0042] The structure of the ignition system of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0043] Such as Figure 1-Figure 3As shown, the ignition system of the present invention includes a double-sleeved gas delivery pipe 22, an ignition device, an oxygen supply device, an air supply device, a self-igniting agent delivery device and a combustion aid delivery device. One end of the double-sleeve gas delivery pipe 22 extends into the ignition borehole 24 and is connected with the ignition device. One end of the double-sleeve air delivery pipe 22 stretches out of the ignition borehole 24, and the outer pipe of this end is selectively communicated with the oxygen supply device and / or the air supply device (that is: it can only be connected with the oxygen supply device or the air supply device It can also be communicated with the oxygen supply device and the air supply device at the same time, and the opening of the pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com