Molten iron desulphurization gun

A technology of hot metal desulfurization and desulfurization gun, which is applied in the field of hot metal desulfurization gun, can solve the problem of ineffective desulfurization time and achieve the effect of improving desulfurization reaction efficiency, improving hot metal desulfurization, and increasing interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

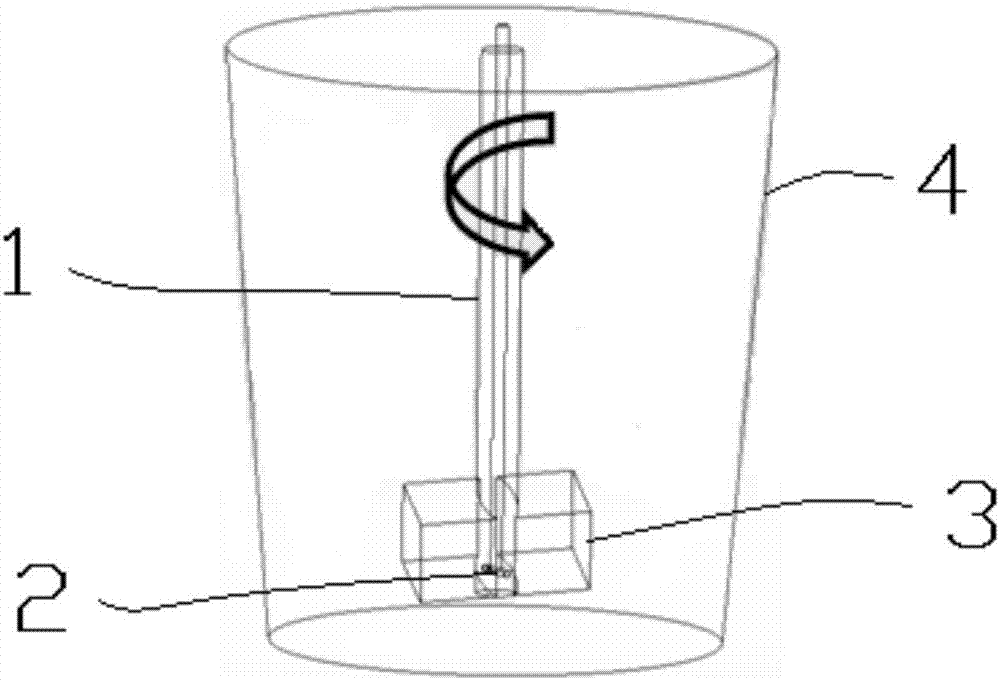

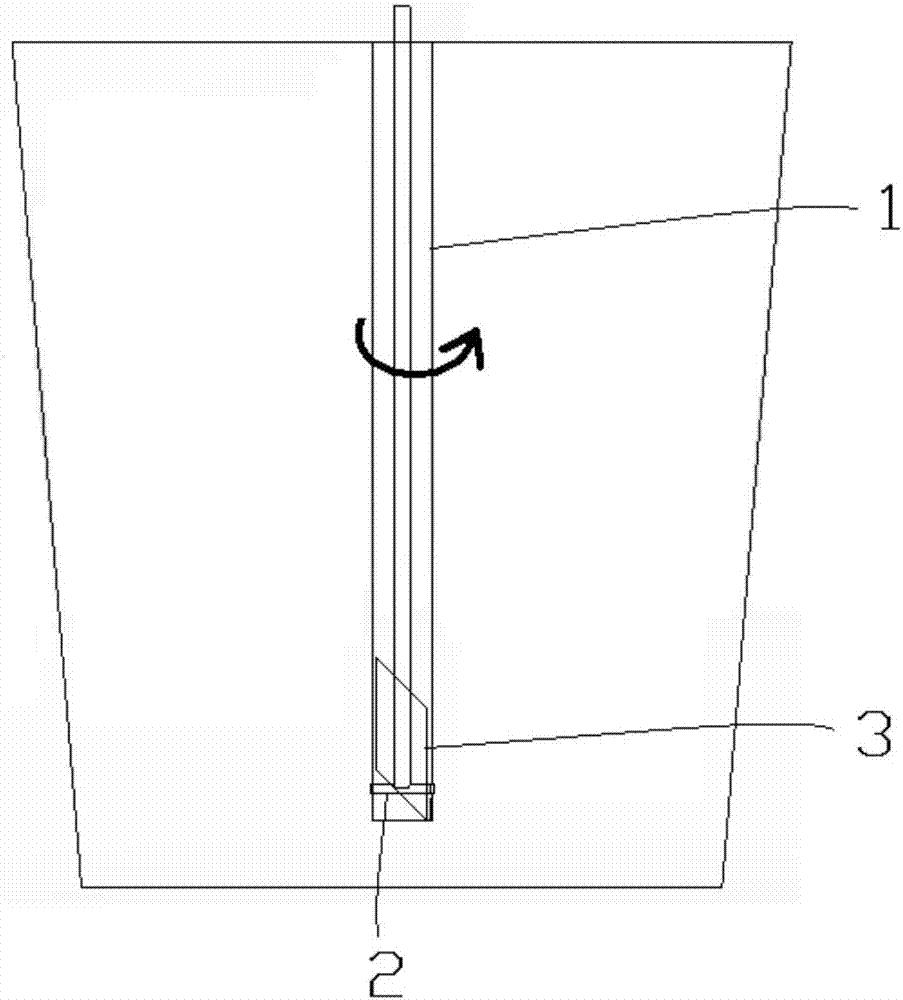

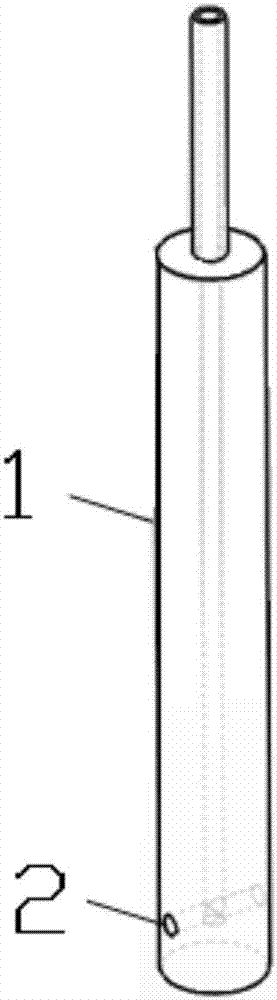

[0015] Such as figure 1 , figure 2 As shown, the present invention includes a desulfurization gun body 1, a spray gun gas outlet 2 is provided on the bottom side of the desulfurization gun body 1, and a paddle 3 is fixedly installed on the side wall of the desulfurization gun body 1, and the paddle 3 is arranged above the spray gun gas outlet 2.

[0016] In order to improve the service life of the paddle 3, the paddle 3 is a steel structure, and the outer surface is provided with a refractory coating.

[0017] In order to increase the interaction between the desulfurizer and molten iron, the paddle 3 is installed as follows: the axis of the paddle 3 is set perpendicular to the axis of the desulfurization gun body 1; The inclination angle between them is 30°~60°, and the inclination angle is preferably 45°. During implementation, it is necessary to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com