Method for degrading nitrites in foods

A nitrite and food technology, applied in the direction of bacteria used in food preparation, food processing, food processing, etc., can solve the problems of insignificant nitrite content and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

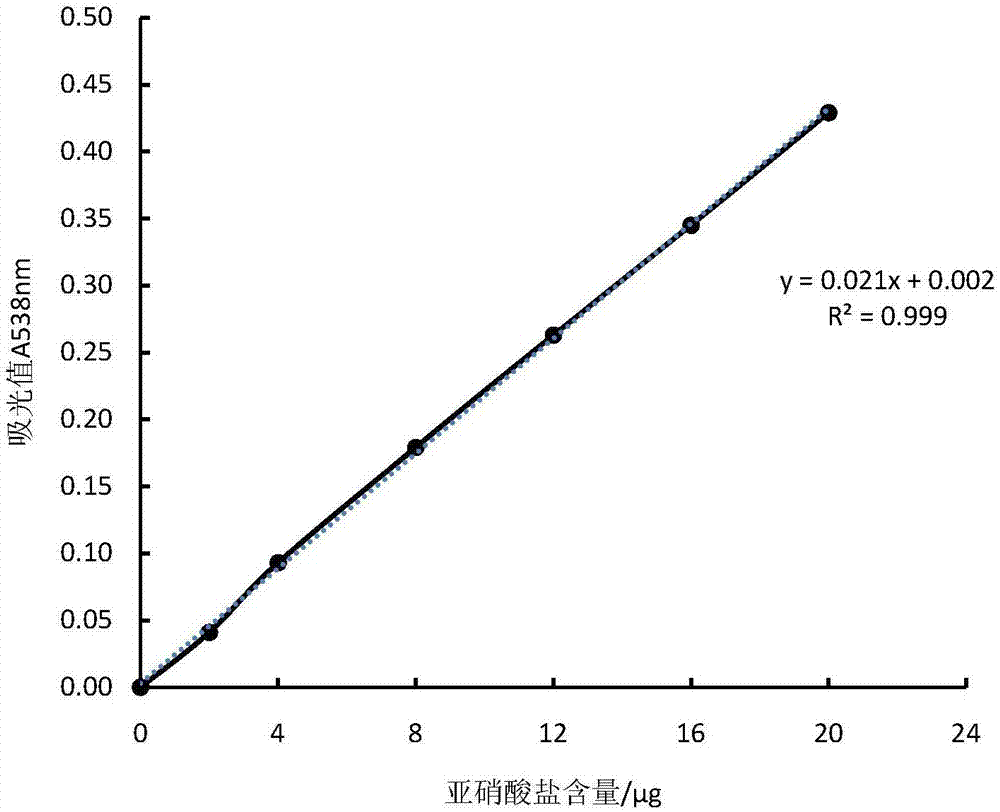

[0041] Example 1 Screening process of synergistic degradation of sodium nitrite by nitrite reductase (recombinant NiR) and malic acid.

[0042] (1) Extract crude enzyme liquid from recombinant Escherichia coli BL21

[0043] ① Bacterial culture: Inoculate the recombinant Escherichia coli BL21 strain (containing the nitrite reductase gene of Lactobacillus casei LCR6013) preserved in the laboratory into the LB liquid medium containing 50 μg / mL ampicillin, at 37°C and 180rpm Cultivate under shaking for 8 hours to obtain seed liquid; inoculate the seed liquid into LB liquid medium containing 50 μg / mL ampicillin at 2% inoculum amount, and culture with shaking at 37° C. and 180 rpm. OD was detected every 30 minutes during shaking culture 600 , when OD 600 When ≈0.6 (logarithmic growth phase), IPTG with a final concentration of 1 mmol / L was added to induce expression, and cultured with shaking at 30° C. and 180 rpm for 4 hours to obtain a culture solution.

[0044] ②Extraction of c...

Embodiment 2

[0072] Example 2 Screening process of synergistic degradation of sodium nitrite by nitrite reductase (natural NiR) and vitamin C.

[0073] (1) Extract crude enzyme liquid from Lactobacillus casei LCR6013

[0074] The activated seed solution was inoculated with 2% volume fraction to contain 100 μg / mL NaNO 2 In the LB liquid medium, cultured on a shaker at 30°C and 180r / min for 24h, centrifuged the medium for 10min (8000r / min, 4°C), discarded the supernatant, washed with sterile water and centrifuged for 10min ( 8000r / min, 4°C), washing and centrifugation were repeated twice to obtain NiR-containing cells and weighed, and the collected cells were suspended in 50mM HEPES buffer (pH 7.4, 5mmol / LDTT, 0.2% trypsin inhibitor) to become The bacterial suspension with a final concentration of 200g / L (wet bacterial weight / buffer solution) was subjected to sonication (35%, 10min, 2s off for 2s) in an ice-bath environment, and after centrifugation for 20min (8000r / min, 4°C), The supernat...

Embodiment 3

[0076] Example 3 Screening process of synergistic degradation of sodium nitrite by nitrite reductase (recombinant NiR) and citric acid.

[0077] (1) Crude enzyme solution extracted from recombinant Escherichia coli BL21

[0078] ① Bacterial culture: inoculate the recombinant Escherichia coli BL21 (containing the nitrite reductase gene of Bacillus cereus LJ01) preserved in the laboratory into LB liquid medium containing 100 μg / mL ampicillin, and inoculate at 37°C and Shake culture at 180 rpm for 12 hours to obtain seed liquid; inoculate the seed liquid into LB liquid medium containing 100 μg / mL ampicillin at 1.5% inoculum amount, and shake culture at 37°C and 180 rpm. OD was detected every 30 minutes during shaking culture 600 , when OD 600 When ≈0.7 (logarithmic growth phase), the expression was induced by adding IPTG at a final concentration of 0.5 mmol / L, and cultured with shaking at 16°C and 180 rpm for 20 hours to obtain a culture solution.

[0079] ②Extraction of crude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com